Three-dimensional ordered macroporous InVO4 visible light-responsive photocatalyst, preparation and application

A three-dimensional ordered, catalyst technology, used in physical/chemical process catalysts, chemical instruments and methods, chemical/physical processes, etc., can solve the problems of uncontrollable products, uneven size, high temperature requirements, and achieve low price, Simple operation and efficient degradation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

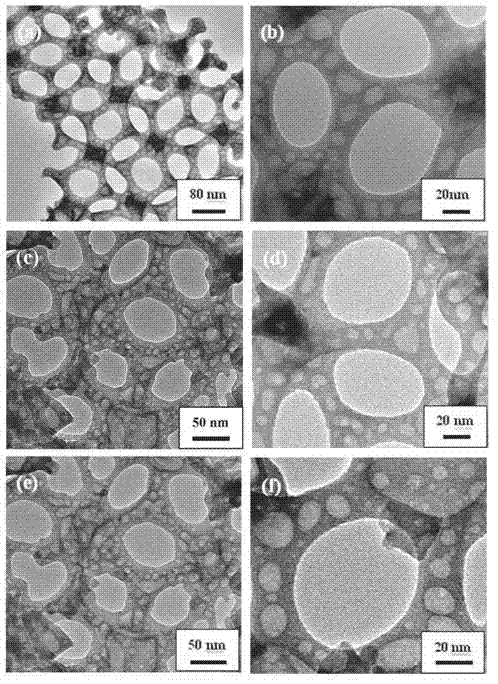

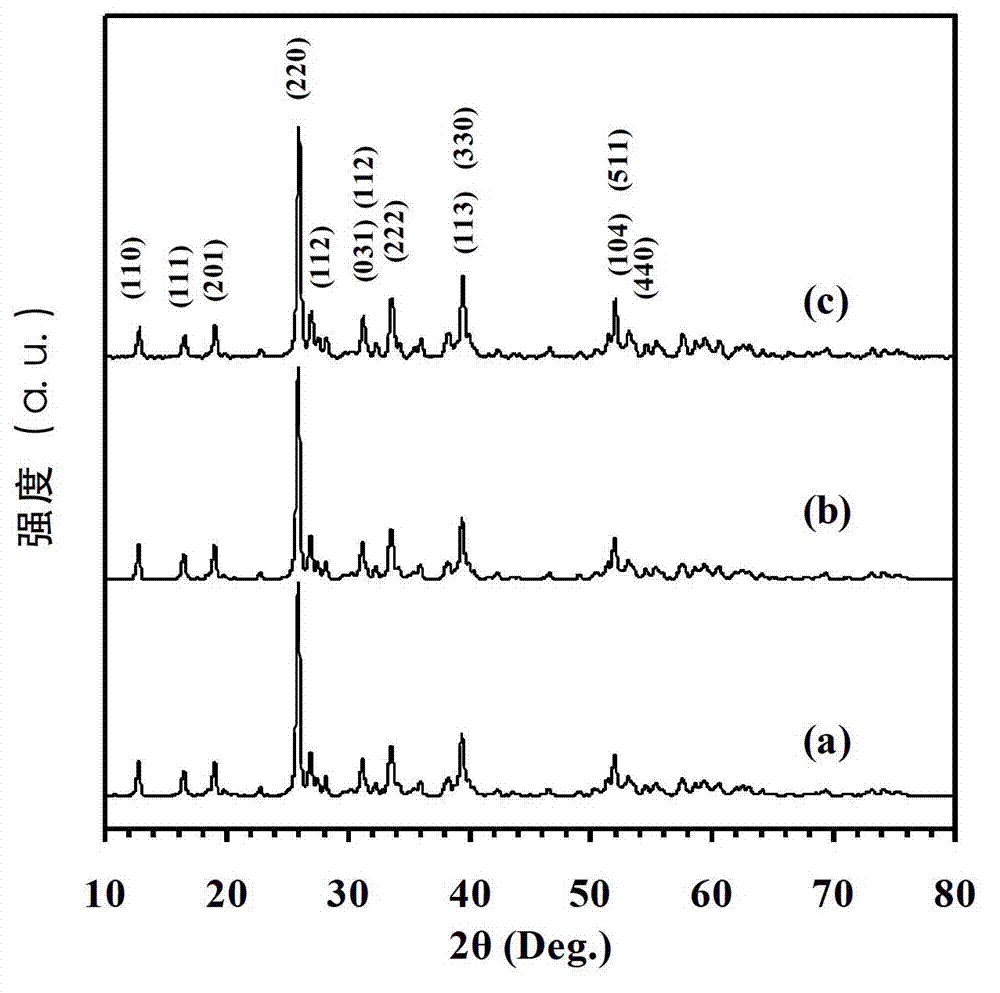

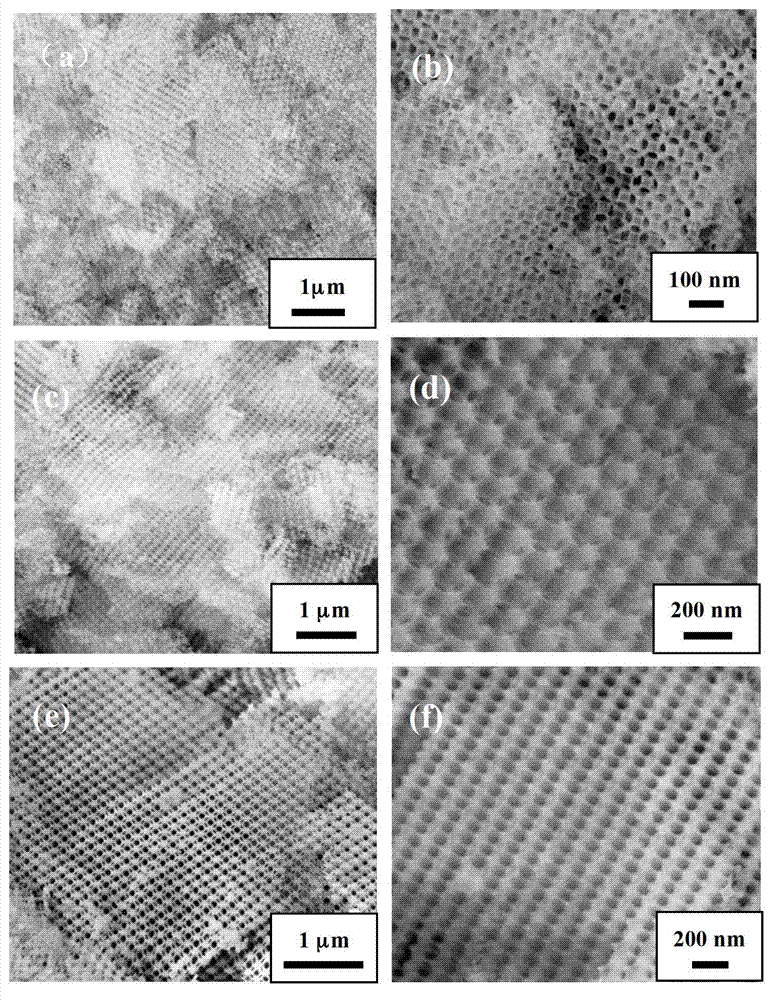

Embodiment 1

[0024] Measure 7ml of deionized water, 6ml of anhydrous methanol, and 3ml of ethylene glycol in a 50ml small beaker, respectively add 10mmol of indium nitrate, 10mmol of citric acid, and 10mmol of ammonium metavanadate under stirring conditions, stir magnetically for 1 hour until completely dissolved, and weigh Take 4g of PMMA template and impregnate in the above precursor solution for 3h, vacuum filter and dry at room temperature for 12h, raise from room temperature to 300°C at a rate of 1°C / min in a tube furnace under nitrogen atmosphere and keep at this temperature 3h, after the furnace temperature was cooled to room temperature, it was raised from room temperature to 500°C at a rate of 1°C / min in an air atmosphere and kept at this temperature for 4h to prepare InVO with a monoclinic three-dimensional ordered macroporous structure. 4 catalyst. The pore diameter is about 166nm, and the mesopore diameter of the pore wall is 2~10nm. Prepare 100ml of MB solution with a concent...

Embodiment 2

[0026] Measure 7ml of deionized water, 6ml of anhydrous methanol, and 3ml of ethylene glycol in a 50ml small beaker, add 10mmol of indium nitrate, 10mmol of tartaric acid, and 10mmol of ammonium metavanadate under stirring conditions, stir magnetically for 1 hour until completely dissolved, and weigh 4g of PMMA templates were immersed in the above precursor solution for 3h, dried at room temperature for 12h after vacuum filtration, raised from room temperature to 300°C at a rate of 1°C / min in a tube furnace under a nitrogen atmosphere and kept at this temperature for 3h , after the furnace temperature was cooled to room temperature, it was raised from room temperature to 500 °C at a rate of 1 °C / min in air atmosphere and kept at this temperature for 4 hours to prepare InVO with a monoclinic three-dimensional ordered macroporous structure. 4 catalyst. The pore diameter is about 142nm, and the mesopore diameter of the pore wall is 2~10nm. Prepare 100ml of MB solution with a con...

Embodiment 3

[0028] Measure 7ml of deionized water, 7.5ml of anhydrous methanol, and 1.5ml of ethylene glycol into a 50ml small beaker, add 10mmol of indium nitrate, 10mmol of ascorbic acid, and 10mmol of ammonium metavanadate under stirring conditions, and stir magnetically for 1 hour until completely dissolved. Weigh 4g PMMA template and immerse in the above precursor solution for 3h, vacuum filter and dry at room temperature for 12h, raise from room temperature to 300°C at a rate of 1°C / min in a tube furnace under a nitrogen atmosphere and at this temperature Keep for 3h, after the furnace temperature is cooled to room temperature, rise from room temperature to 500°C at a rate of 1°C / min in air atmosphere and keep at this temperature for 4h to prepare InVO with monoclinic three-dimensional ordered macroporous structure 4 catalyst. The pore diameter is about 138nm, and the mesopore diameter of the pore wall is 2~10nm. Prepare 100ml of MB solution with a concentration of 10mg / L in a quar...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| energy | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com