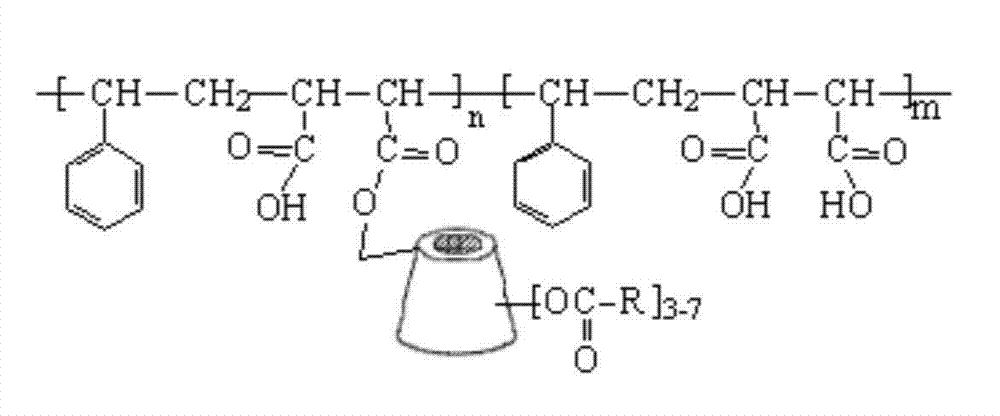

Cyclodextrin immobilized macromolecular polymer and preparation method and application thereof

A high-molecular polymer and cyclodextrin technology, applied in chemical instruments and methods, other chemical processes, adsorption water/sewage treatment, etc., can solve problems such as non-absorbable materials, and achieve simple preparation methods, easy industrialization, and raw material sources Wide and cheap effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] Put 3.0g styrene-maleic anhydride copolymer and 25.0g dry β-cyclodextrin in 60ml N,N-dimethylformamide, react at 50°C for 10h, remove most of the solvent under reduced pressure, and use 30°C Warm water washes the residue repeatedly to obtain β-cyclodextrin-immobilized styrene-maleic anhydride copolymer.

[0021] Dissolve 5.0 g of the solid substance in 80 ml of DMF, add 3.0 g of chloroacetyl chloride, and then raise the temperature to 90° C. for 24 hours. Most of the solvent was distilled off under reduced pressure, and the residue was washed with warm water at 50°C to obtain a cyclodextrin-immobilized polymer.

Embodiment 2

[0023] Put 3.0g styrene-maleic anhydride copolymer and 25.0g dry carboxymethyl-β-cyclodextrin in 60ml N,N-dimethylformamide, react at 70°C for 24h, remove most of the solvent under reduced pressure, Repeated washing of the detergent residue with warm water at 30°C yielded carboxymethyl-β-cyclodextrin immobilized styrene-maleic anhydride copolymer.

[0024] Dissolve 5.0 g of the solid substance in 80 ml of DMF, add 3 g of propionyl chloride dropwise, and raise the temperature to 70° C. for 24 h. Most of the solvent was distilled off under reduced pressure, and the residue was washed with warm water at 50°C to obtain a cyclodextrin-immobilized polymer.

Embodiment 3

[0025] Example 3: Adsorption of cyclodextrin-immobilized polymers to organic basic dyes

[0026] Put 0.025g of cyclodextrin-immobilized polymer in 100ml of a certain concentration of organic basic dye basic fuchsin (methylene blue) solution, seal it, and stir at a certain temperature for 12h. Centrifuge to remove the adsorbent, measure the concentration of the solution before and after adsorption with a UV-Vis spectrophotometer, and calculate the adsorption amount and adsorption rate.

[0027] The results show that: at 35°C, the saturated adsorption capacity of the adsorbent for basic fuchsin and methylene blue calculated by the Langmuir isotherm adsorption equation is 170 mg.g -1 and 200 mg.g -1 ; For an initial concentration of 50 mg.L -1 The following basic dye removal rate is above 98%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com