Method for preparing photonic crystal fiber for light-catalyzed reaction

A technology of photonic crystal fiber and photocatalytic reaction, which is applied in the direction of catalyst carrier, chemical instrument and method, cladding fiber, etc., which can solve the problems of hindered light penetration, difficulty in separation and recovery of catalyst, and loss of activity, so as to improve contact Effects of area and reaction time, high energy density, and improved utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

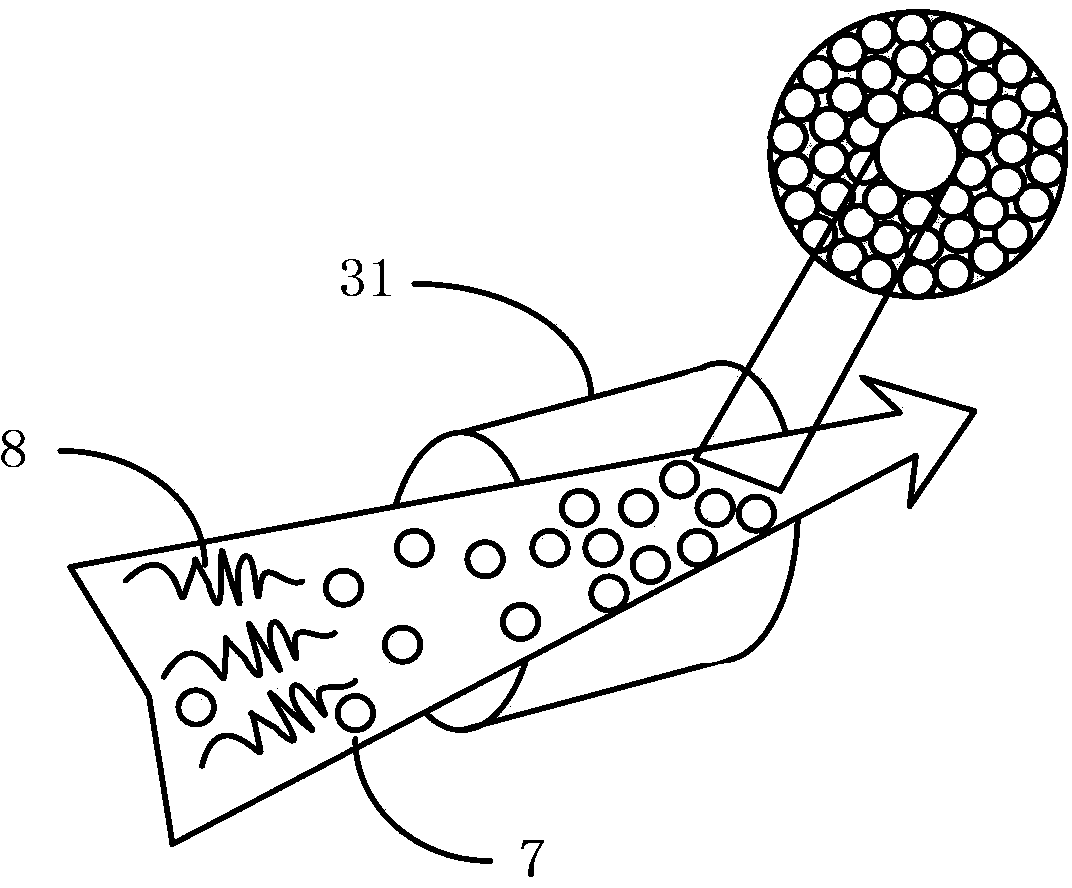

[0030] In the embodiment of the present invention, by using the photonic crystal fiber as the light transmission medium and the carrier of the catalyst, and at the same time as the transport channel of the reactant, combined with the laser, it has the advantages of high energy density, high beam quality, high electro-optical conversion efficiency, and easy fiber coupling. , effectively improving the contact area and reaction time between the gaseous reactant and the catalyst, as well as the utilization rate of laser energy.

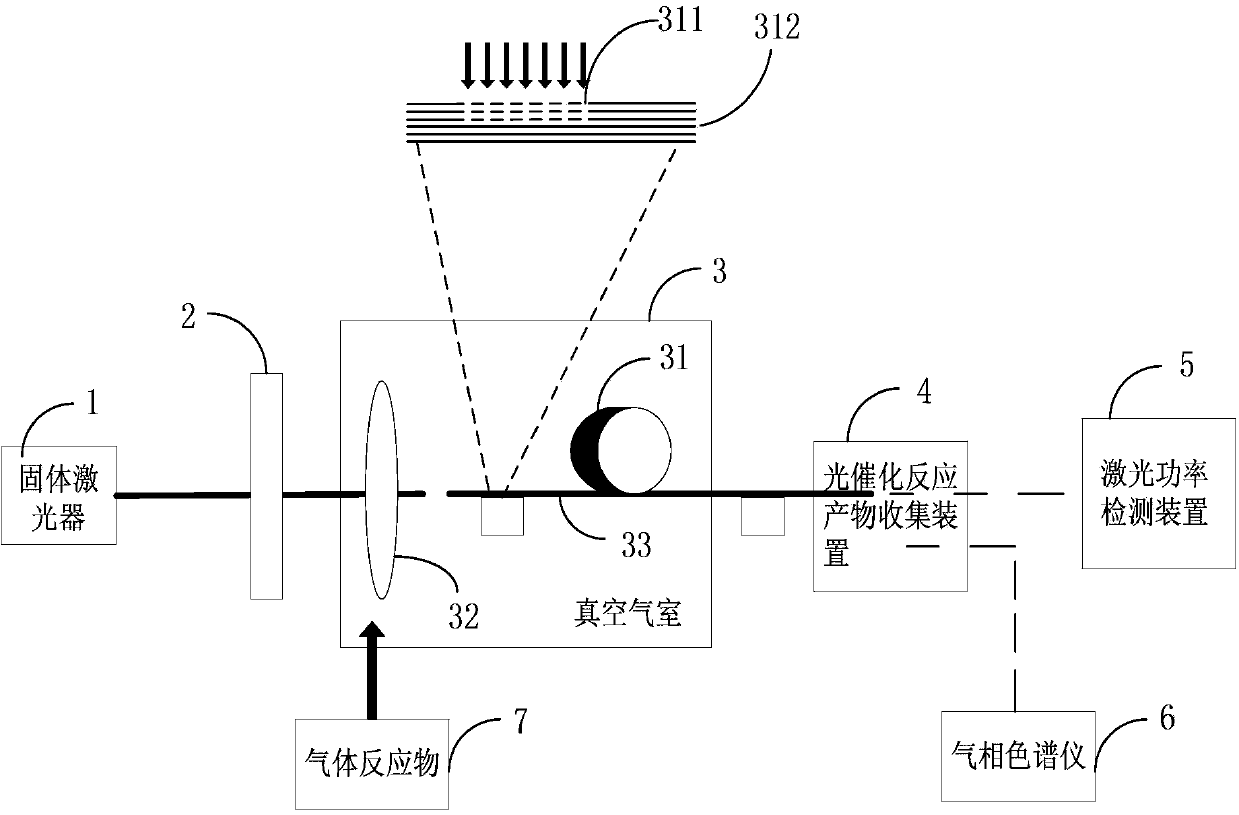

[0031] Such as figure 1 Shown is a schematic diagram of the structure of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com