Agglomerate cyclone separator

A cyclone separator and cyclone separation technology, applied in the direction of separation methods, dispersed particle separation, chemical instruments and methods, etc., can solve problems such as easy fluctuations, easy blockages, unstable impurity content, etc., and achieve high separation efficiency. The effect of small floor area and compact equipment structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

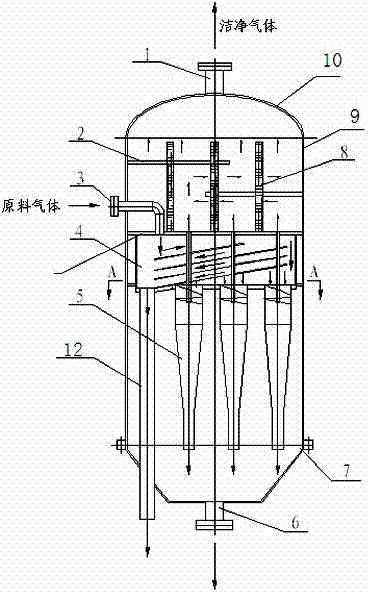

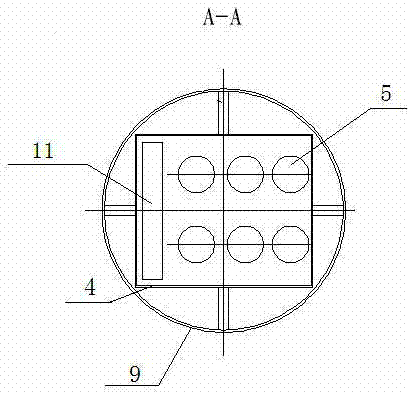

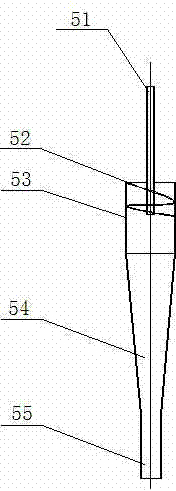

[0018] Such as figure 1 As shown, it includes a natural gas outlet 1, a baffle plate 2, a natural gas inlet 3, a louver separator 4, a cyclone pipe 5, a sewage outlet 6, an ash hopper 7, a coalescing filter element 8, an outer cylinder 9, and an upper head 10.

[0019] The above-mentioned outer cylinder 9 is vertical, and the ratio of cylinder height to diameter is between 1:1 and 2:1. The outer cylinder 9 is divided from top to bottom along the axial direction into a coalescing and filtering zone, an inertial separation zone, and a cyclone. In the separation area, the upper end of the outer cylinder 9 is provided with an upper head 10, and the center of the upper head 10 is provided with a natural gas outlet 1, and the lower end of the outer cylinder 9 is provided with an ash hopper 7, and the center of the bottom end of the ash hopper 7 is provided with a sewage outlet 6.

[0020] The louver separator 4 is set in the inertial separation area. The baffle length of the louver ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com