Field emergency non-woven isolation hood operating room

A non-woven fabric and operating room technology, which is applied in the field of medical equipment, can solve the problems of high cost of mobile surgical vehicles, unsuitable for strategic reserves, and inability to participate in medical treatment, etc., and achieves the effect of low cost and low price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be described in further detail below in conjunction with the accompanying drawings.

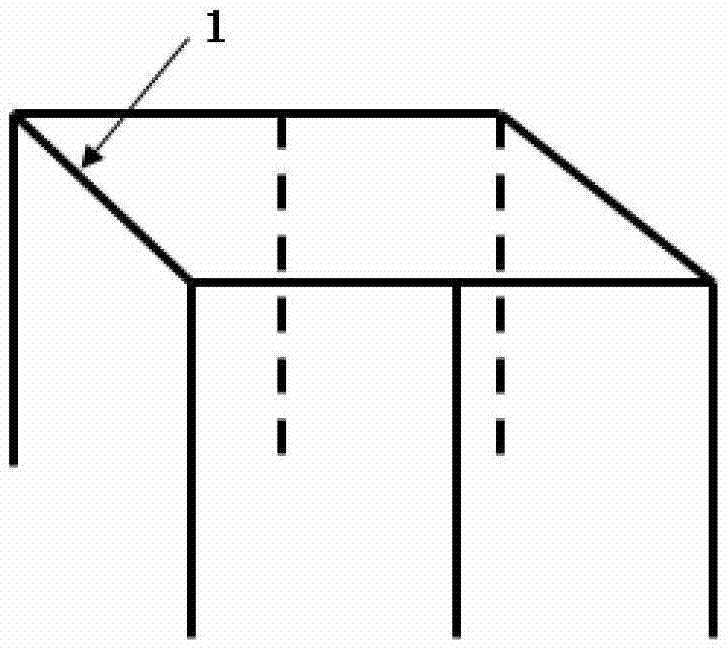

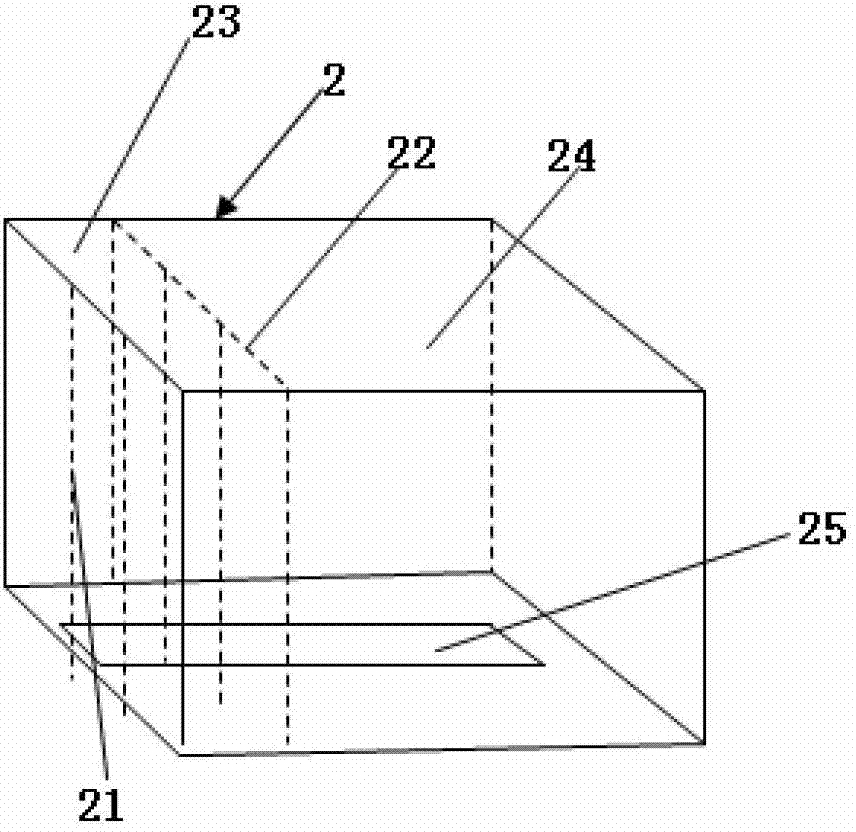

[0022] see Figure 1 to Figure 3 As shown, the present invention is a field first aid non-woven isolation cover operating room, including a bracket 1 and a filter cover 2 supported by the bracket 1 .

[0023] The support 1 is a square support assembled from a plurality of steel pipes with a diameter of 16mm, and its height is 2 meters, its length is 3.5 meters, and its width is 2.5 meters.

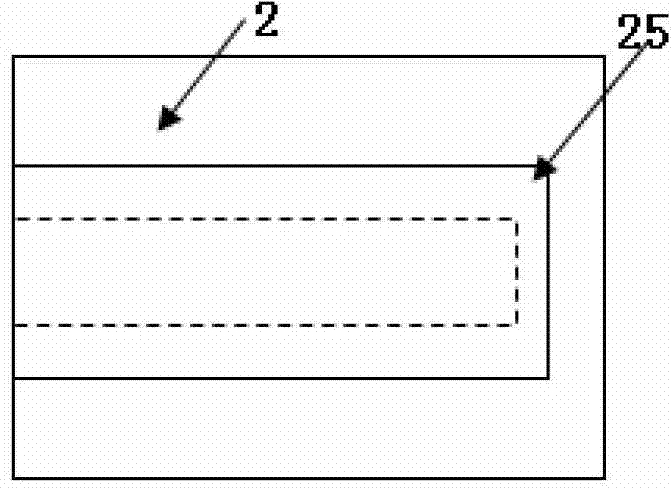

[0024] The filter cover 2 covers the outer periphery of the bracket 1, and wraps the top and the five sides of the bracket 1; the material length of the four sides of the filter cover 2 is greater than the height of the bracket, so that the filter cover 2 covers the bracket 1 After being put on, the materials on the four sides of the filter cover 2 can be laid flat on the ground, which can facilitate the quick installation of the filter cover 2 . When assembling, carry ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com