Quasi-close loop starting method of brushless direct current motor free of position sensor

A brushed DC motor and sensor technology, applied in the field of mechanical engineering, can solve problems such as out-of-step, back EMF zero-crossing detection cannot be effectively detected, and the rotor position cannot be predicted

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

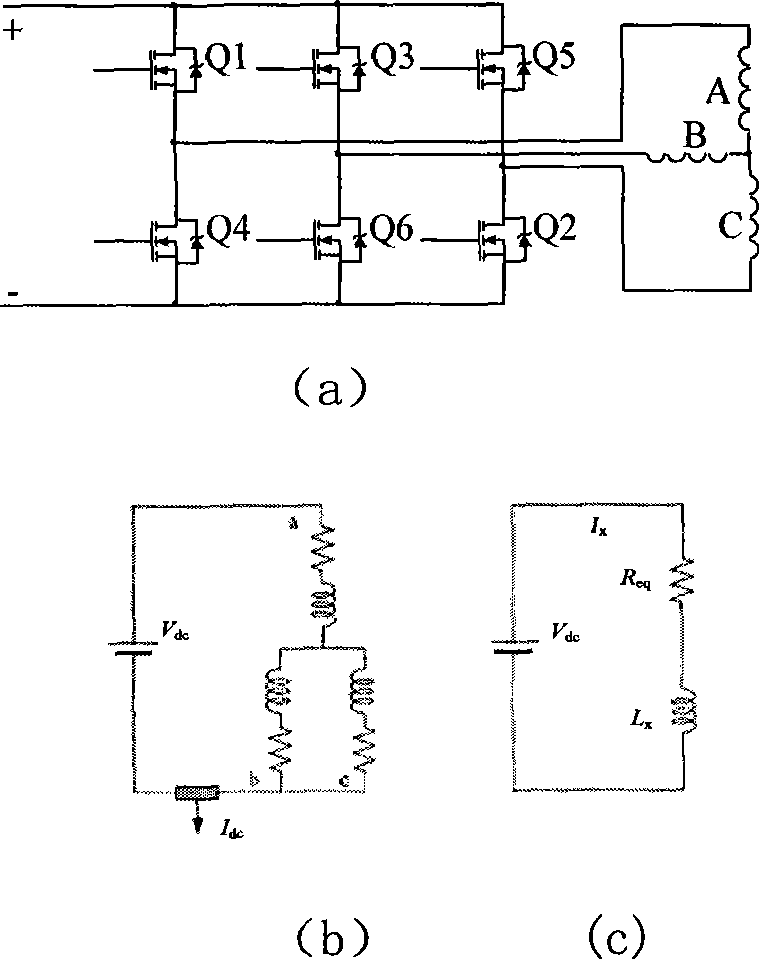

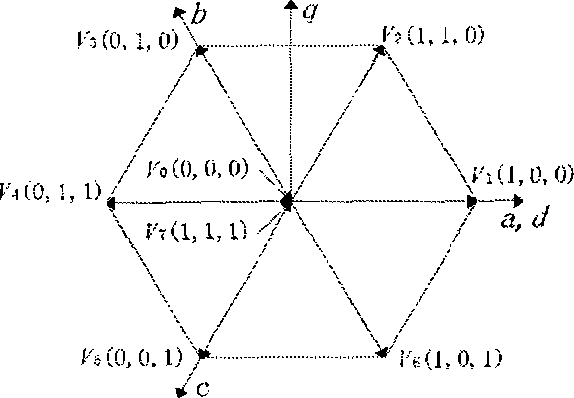

Method used

Image

Examples

Embodiment 1

[0109] The sensorless brushless DC motor control system test platform consists of a brushless DC motor body, a DSP (TMS3202812) control board, a power drive board, a magnetic powder brake, and measuring instruments. During the test, the H_PWM-L_PWM modulation method is adopted, the PWM modulation carrier frequency is 20KHz, the positioning detection pulse period is set to 10μs, and the motor parameters are shown in Table 7. The magnetic powder brake is the load of the motor test system. The excitation current of 0.1A is passed into the magnetic powder brake, that is, the load torque is set to 1N.m.

[0110] Table 7 Motor parameters

[0111]

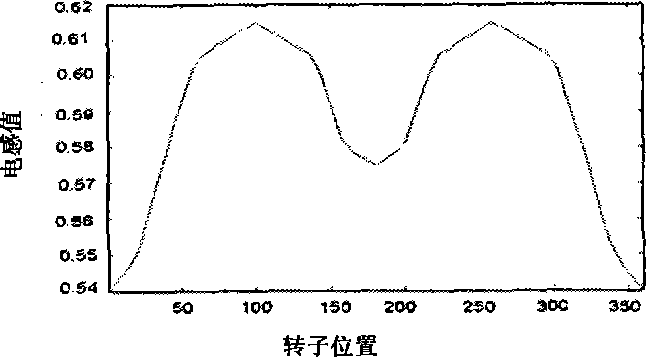

[0112] After measuring the equivalent time constant of the motor is 10μs, in this example the period of the short pulse voltage vector is 10μs. Figure 8 The starting waveform of the quasi-closed-loop starting mode proposed by the present invention is adopted when the rotating speed of the motor test platform is set to 2000rpm. Figu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com