Preparation method and application method for zinc cathode active material of zinc-nickel secondary battery

A secondary battery, active material technology, applied in battery electrodes, alkaline battery electrodes, circuits, etc., can solve problems such as performance dependence, achieve the effects of slowing migration, adjustable material composition, and resisting impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

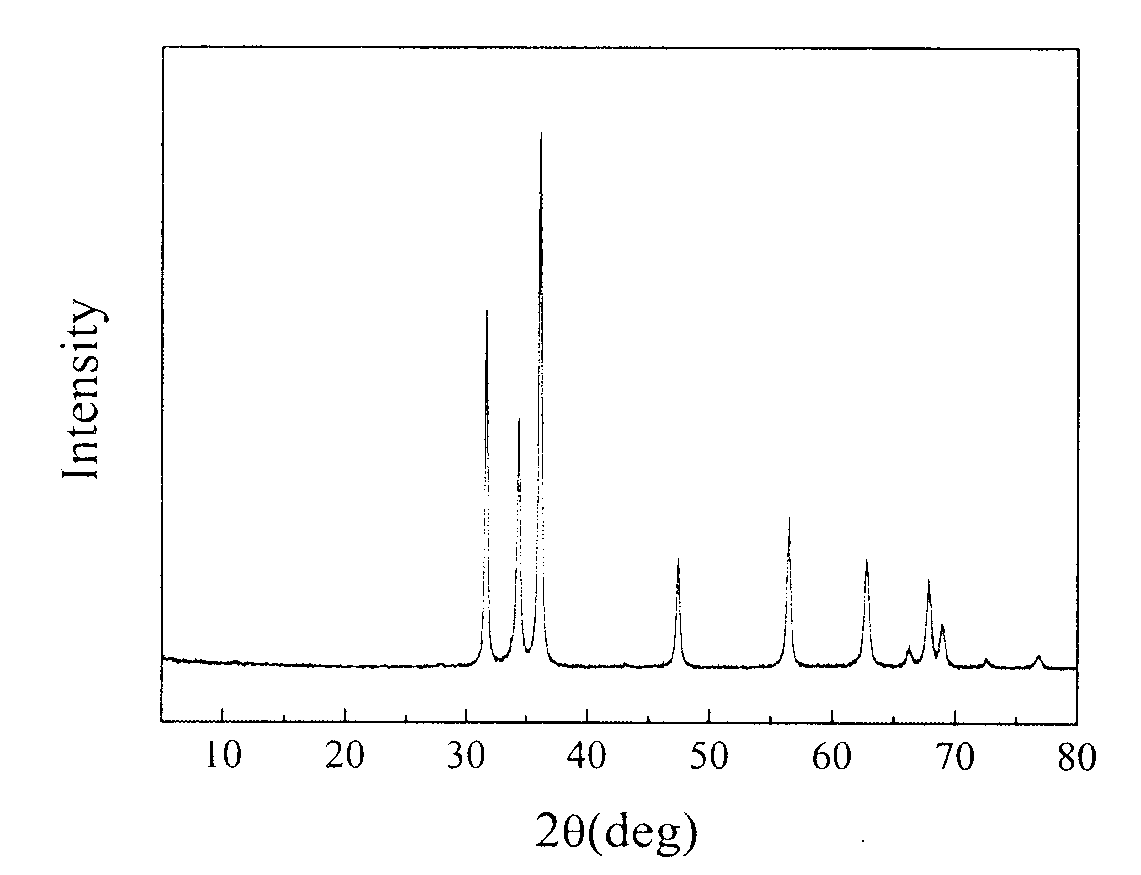

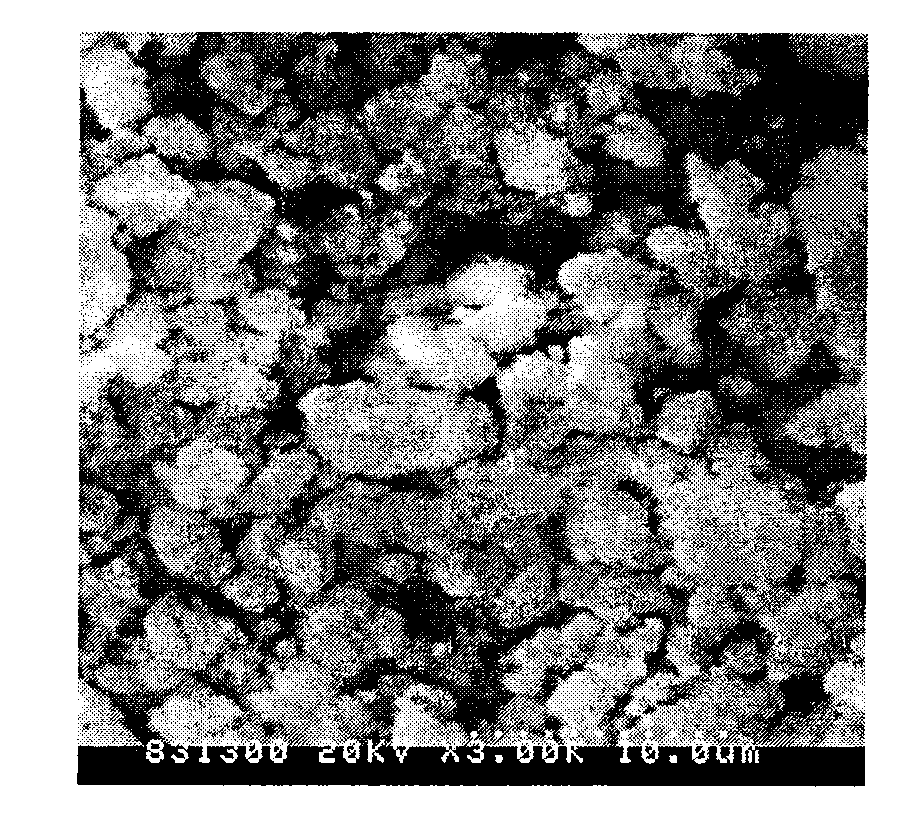

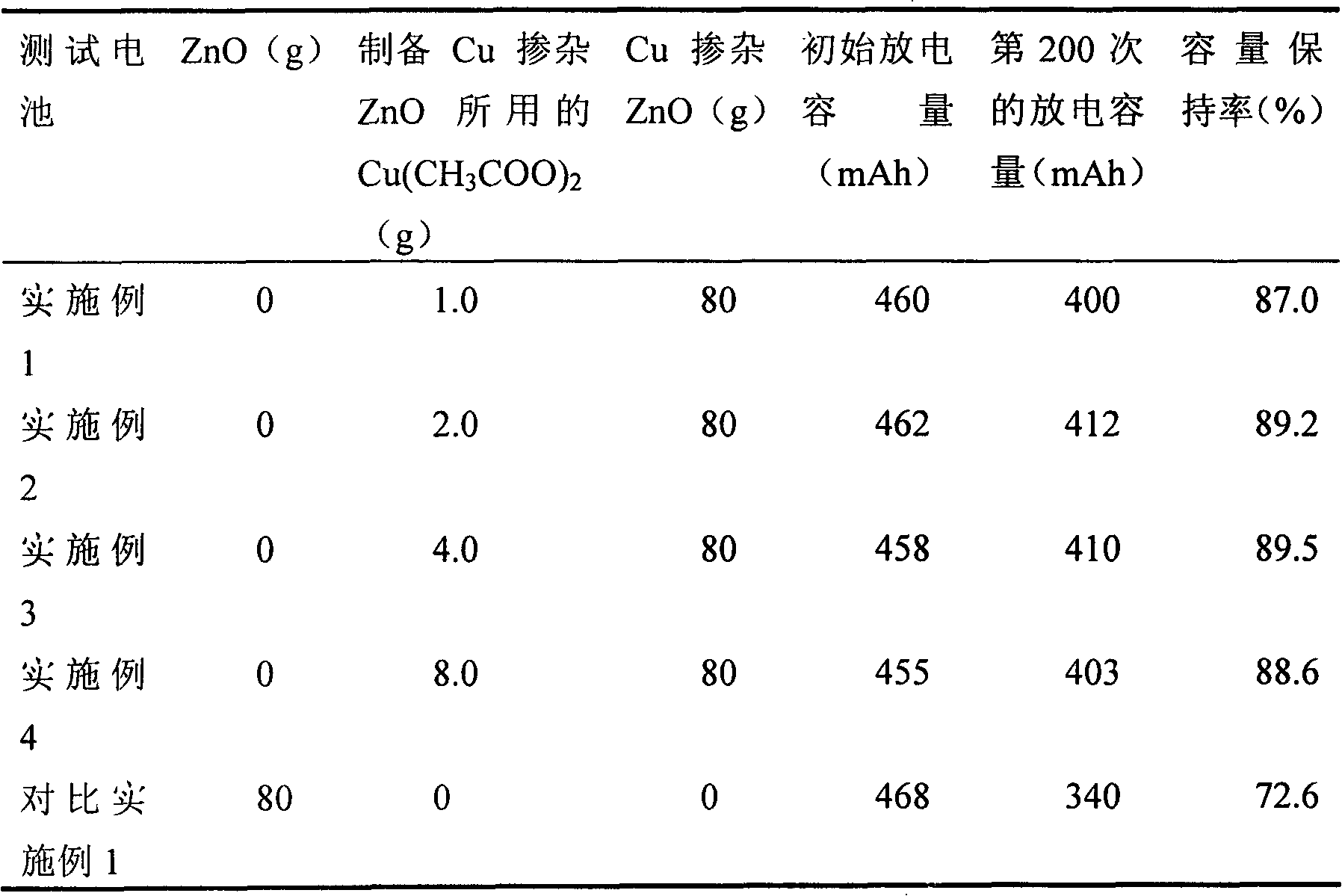

Embodiment 1

[0027] 1 part by weight of analytically pure Cu(CH 3 COO) 2 , 100 parts by weight of analytically pure Zn(CH 3 COO) 2 15 parts by weight of analytically pure urea are dissolved in 300 parts by weight of deionized water to form a transparent mixed solution. The above-mentioned mixed solution was ultrasonically dispersed for 10 minutes, and then transferred to a hydrothermal reaction kettle, and the reaction kettle was placed in an oven at 300° C. for 5.0 hours. Finally, the obtained precipitate was filtered, washed, dried at 80° C. for 3.0 h, and calcined at 600° C. for 2.0 h to obtain Cu-doped ZnO. Put 0.1g sodium dodecylbenzenesulfonate and 0.1g hexadecyltrimethylammonium bromide in a beaker, add 35g distilled water, place the beaker on an electric heating stirrer and stir slowly until the dodecyl trimethylammonium bromide After sodium phenylsulfonate and cetyltrimethylammonium bromide are completely dissolved, add 95g of Cu-doped ZnO and other zinc compounds, 3.5g of gra...

Embodiment 2

[0029] 2 parts by weight of analytically pure Cu(CH 3 COO) 2 , 125 parts by weight of analytically pure Zn(CH 3 COO) 2 25 parts by weight of analytically pure urea are dissolved in 315 parts by weight of deionized water to form a transparent mixed solution. The above-mentioned mixed solution was ultrasonically dispersed for 10 minutes, and then transferred to a hydrothermal reaction kettle, and the reaction kettle was placed in an oven at 300° C. for 5.0 hours. Finally, the obtained precipitate was filtered, washed, dried at 80° C. for 3.0 h, and calcined at 600° C. for 2.0 h to obtain Cu-doped ZnO. Put 0.1g sodium dodecylbenzenesulfonate and 0.1g hexadecyltrimethylammonium bromide in a beaker, add 35g distilled water, place the beaker on an electric heating stirrer and stir slowly until the dodecyl trimethylammonium bromide After sodium phenylsulfonate and cetyltrimethylammonium bromide are completely dissolved, add 95g of Cu-doped ZnO and other zinc compounds, 3.5g of gr...

Embodiment 3

[0031] 4 parts by weight of analytically pure Cu(CH 3 COO) 2 , 125 parts by weight of analytically pure Zn(CH 3 COO) 225 parts by weight of analytically pure urea are dissolved in 315 parts by weight of deionized water to form a transparent mixed solution. The above-mentioned mixed solution was ultrasonically dispersed for 10 minutes, and then transferred to a hydrothermal reaction kettle, and the reaction kettle was placed in an oven at 300° C. for 5.0 hours. Finally, the obtained precipitate was filtered, washed, dried at 80° C. for 3.0 h, and calcined at 600° C. for 2.0 h to obtain Cu-doped ZnO. Put 0.1g sodium dodecylbenzenesulfonate and 0.1g hexadecyltrimethylammonium bromide in a beaker, add 35g distilled water, place the beaker on an electric heating stirrer and stir slowly until the dodecyl trimethylammonium bromide After sodium phenylsulfonate and cetyltrimethylammonium bromide are completely dissolved, add 95g of Cu-doped ZnO and other zinc compounds, 3.5g of gra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com