Testing system and testing method for air tightness of main valve body component of 120 valve

An air tightness test, main valve body technology, applied in the direction of using liquid/vacuum degree for liquid tightness measurement, by measuring the acceleration and deceleration rate of fluid, etc., can solve the sealing reliability of clamping and micro leakage slide valve sleeve The problems such as the failure to detect the leakage of the gas path and the atmosphere, affecting the pass rate of the first-time inspection of the final assembly, and the inability to quantify the leakage value, achieve the effect of fast sealing, low cost and strong function

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

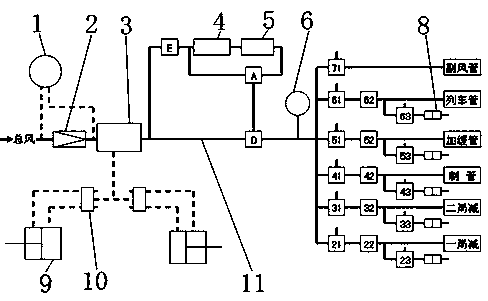

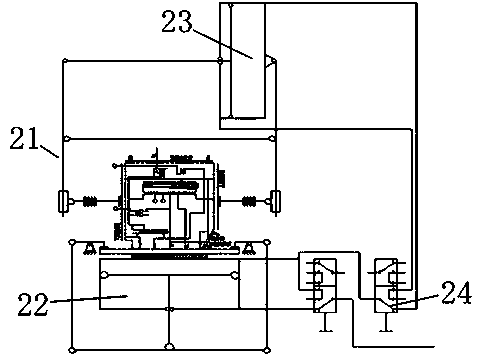

[0026] A 120-valve main valve body constitutes an airtight test system, such as figure 1 and figure 2 As shown, it includes: double-needle pressure gauge 1, pressure regulating valve 2, air storage cylinder 3, stable air cylinder 4, differential pressure gauge 5, pressure transmitter 6, two-position three-way solenoid valve (21, 31, 41 , 51, 61, 71, 23, 33, 43, 53, 63, A, D), micro transmitter 8, cylinder 9, two-position five-way solenoid valve 10, copper tube 11, two-position two-way solenoid valve (22, 32, 42, 52, 62, E), a control system composed of programmable logic controller (PLC) and programmable touch screen, and an actuator composed of cabinet, bench, clamping mechanism and sealing structure. in:

[0027] The programmable logic controller (PLC) is the central control unit of the test system, which realizes functions such as logic control of each solenoid valve, test data detection, calculation, judgment and storage.

[0028] The programmable touch screen performs...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com