Energy-saving gas stove

A stove and gas technology, which is applied to heating fuels, household stoves/stoves, gaseous heating fuels, etc., can solve the problems of rising use costs, low combustion completeness, indurability, etc., and achieves simple and convenient maintenance and use, improved thermal efficiency, Easy ignition effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

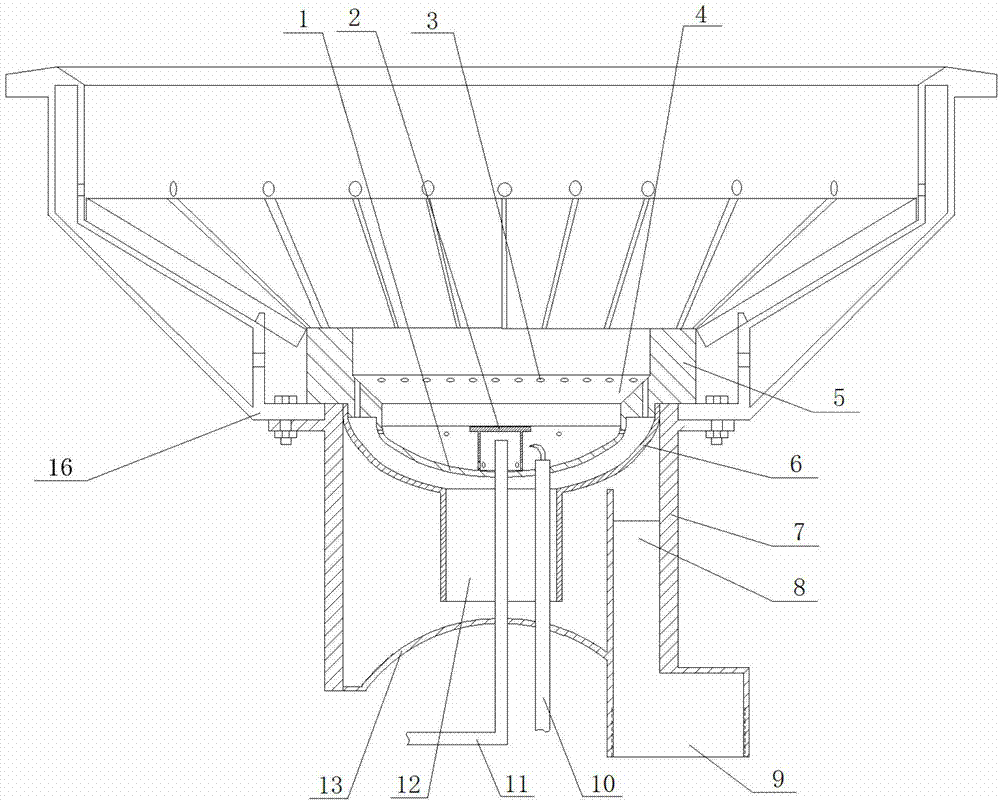

[0022] Such as figure 1 and figure 2 As shown, an energy-saving gas cooker head includes a furnace 16, a flame nozzle 5, an open flame cover 2, an open flame mixing gas pipe 11 and an ignition wire 10; Guide cover 6 and gas mixing chamber 7 positioned under the guide cover;

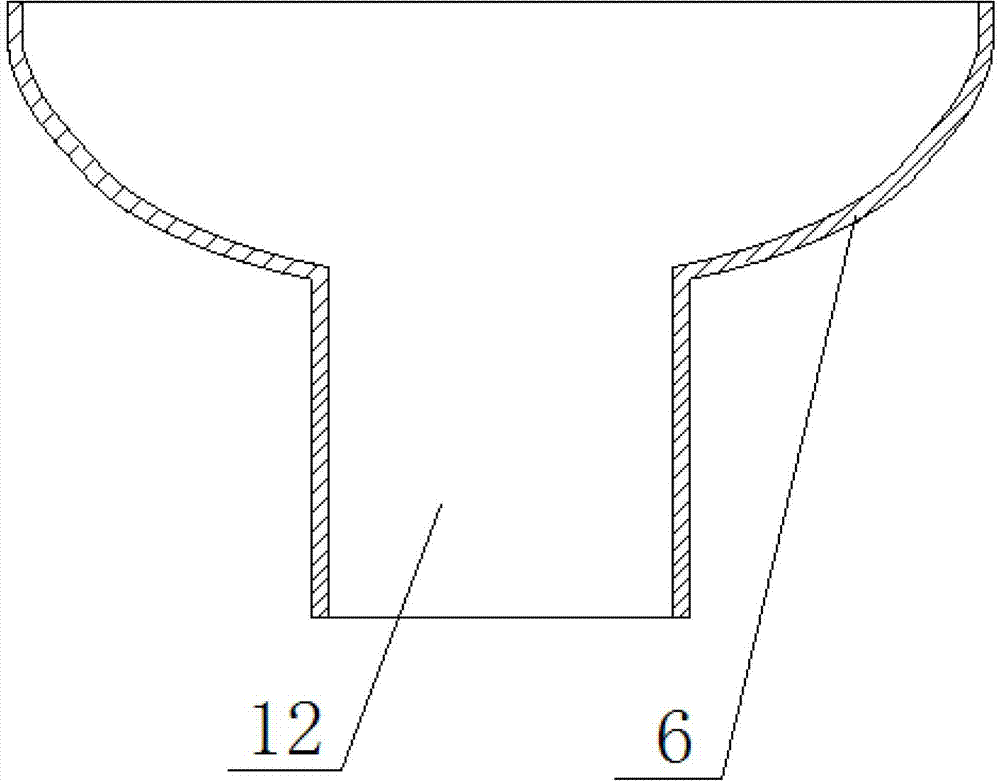

[0023] Such as image 3 As shown, the upper part of the guide cover 6 is a concave spherical surface, and the lower part is a tubular guide cover tube 12, and the upper opening communicates with the lower part;

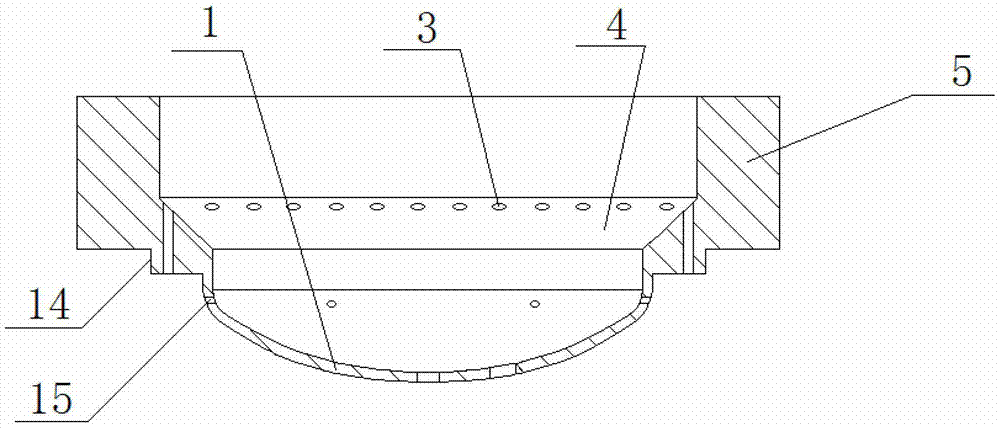

[0024] Such as figure 1 and figure 2 As shown, the fire nozzle 5 is located at the middle and lower part of the hearth 16, and its upper part is tubular, and the lower part of the tube is provided with an inclined plane boss 4 along the circumferential direction, and the inclined fire nozzle 3 is arranged on the inclined plane boss. Concave spherical surface 1, a number of combustion-supporting fire injection holes 15 are distributed along the circumferential direction on the side of the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com