High-toughness electric conduction nylon composite material and preparation method thereof

A nylon composite material, high toughness technology, applied in the field of nylon composite materials, can solve the problems of difficult to bear heavy load, nylon electrical insulation, high water absorption, limited application range, etc. low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~9

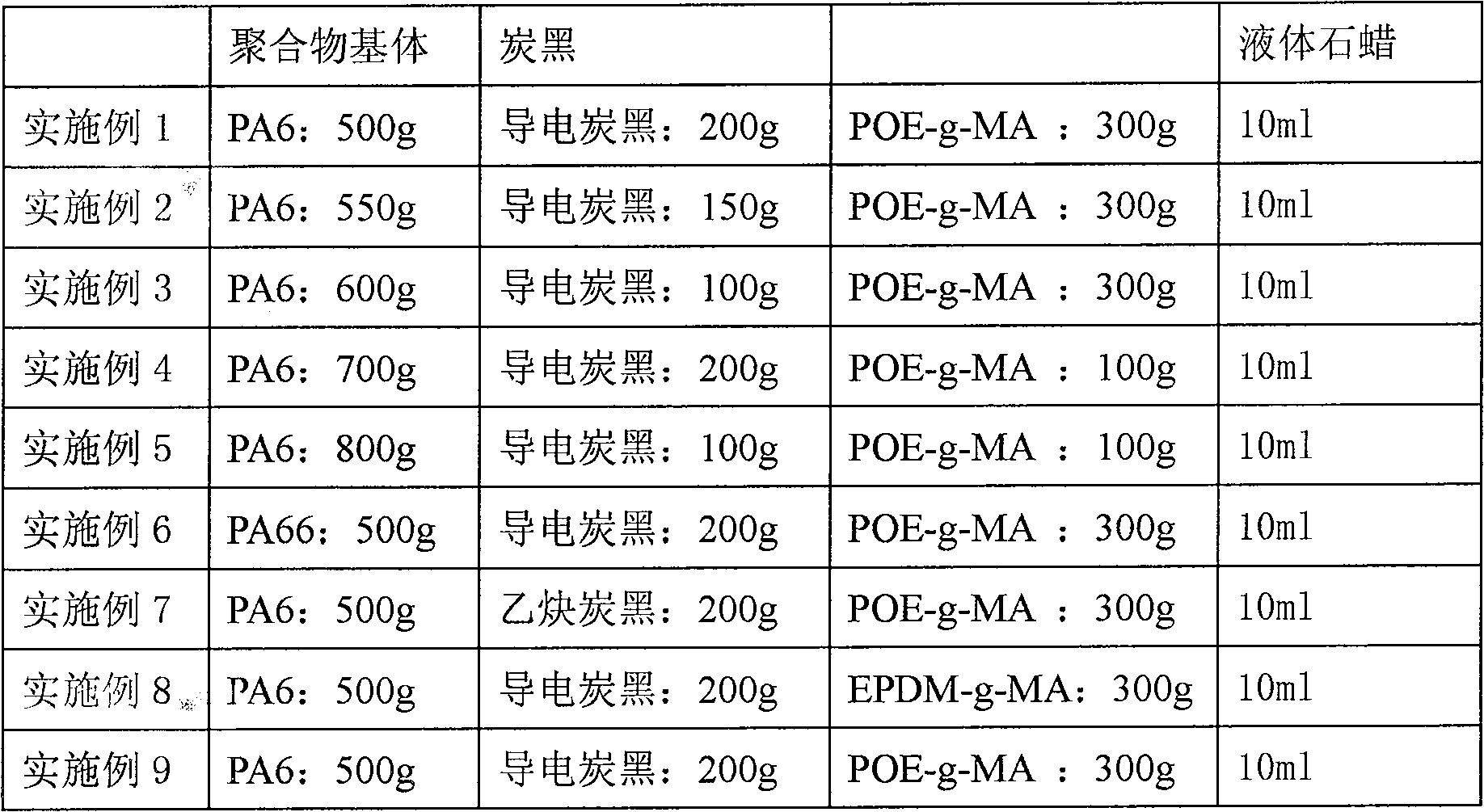

[0040] Take the raw materials according to the ratio shown in Table 1:

[0041] Table 1:

[0042]

[0043] in:

[0044]The preparation method of Examples 1-5 is as follows: weigh the dried polymer matrix slices, conductive carbon black, maleic anhydride grafted ethylene-octene copolymer (POE-g-MA), add 10ml liquid paraffin and mix well It is directly added into a twin-screw extruder with an aspect ratio of 25, melted and kneaded at a temperature of 220 / 230 / 240 / 240 / 235°C, and granulated. The screw speed is 62r / min. After the pellets are dried, they are injection molded into test samples. The injection molding temperature is 230 / 245 / 250 / 250 / 245°C, the injection pressure is 80MPa, and the mold temperature is 80°C. The performance test results of the obtained composite materials are shown in Table 2.

[0045] The preparation method of Examples 6-8 is as follows: weigh the dried polymer matrix slices, conductive carbon black, and ethylene-octene copolymer grafted with maleic...

Embodiment 9

[0046] The preparation method of Example 9 is as follows: Weigh 500g of dried PA6 slices, 200g of conductive carbon black, and 300g of POE-g-MA, add 10ml of liquid paraffin and mix evenly, add to a double-roller mill for mixing, and the mixing temperature is 240°C , The mixing time is 15min. After mixing, the compound was preheated at 245°C for 10 minutes without pressure, and then hot-pressed at 10 MPa for 10 minutes to prepare test samples. The performance test results of the obtained composite materials are shown in Table 2.

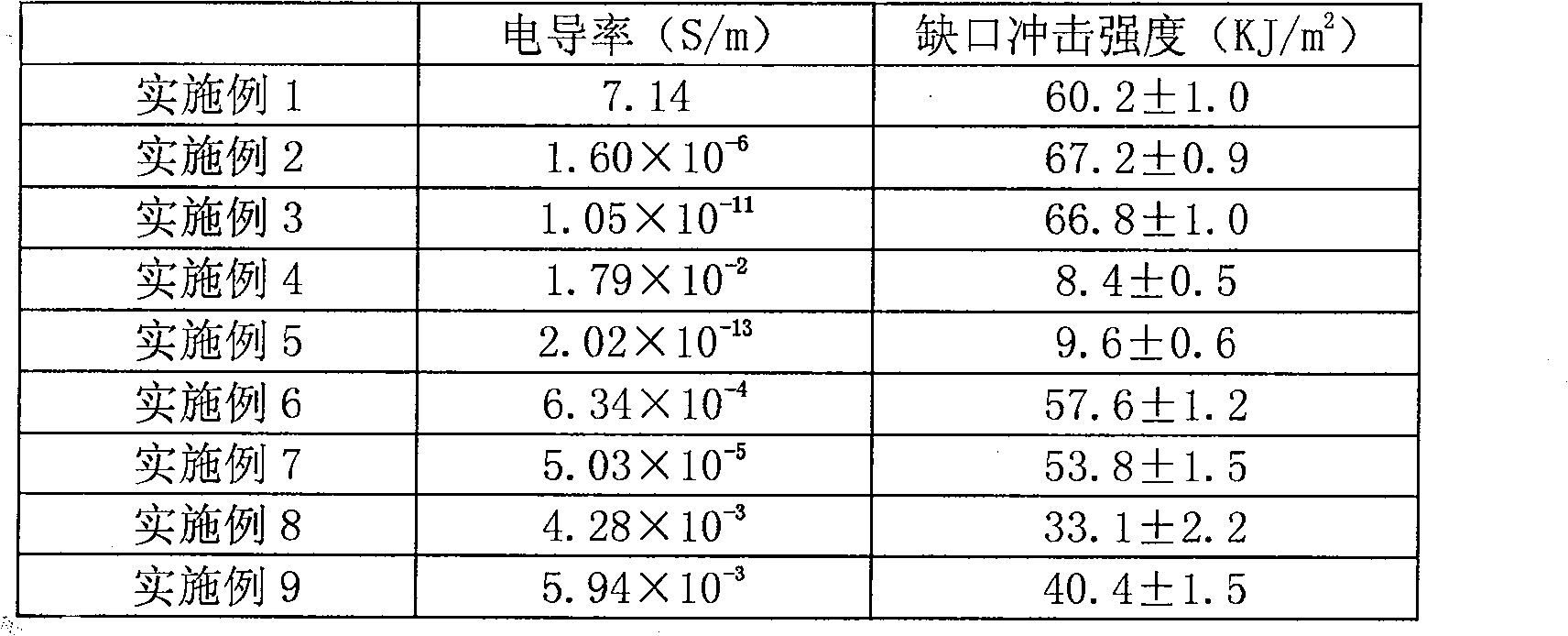

[0047] Table 2: Composite performance test results

[0048]

Embodiment 1

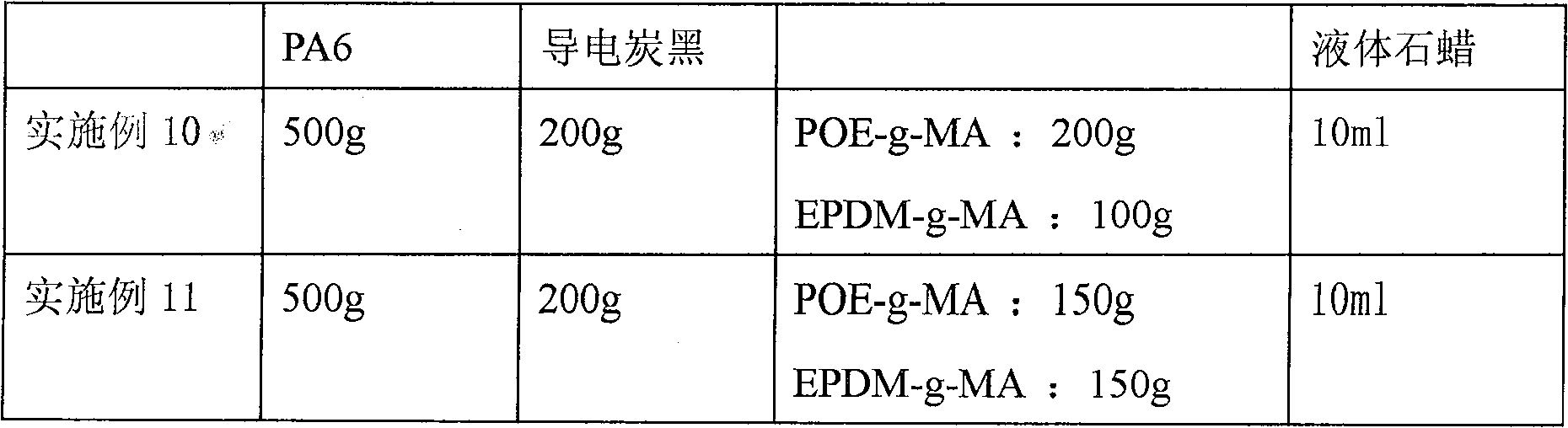

[0050] Examples 10-14 weighed the raw materials according to the proportions in Table 3, the preparation method was the same as that of Example 1, and the performance test results of the obtained composite materials were shown in Table 4.

[0051] table 3:

[0052]

[0053]

[0054] Table 4: Composite performance test results

[0055]

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com