Electric connector capable of being electromagnetically unlocked and assembly of electric connector

An electrical connector and unlocking technology, which is applied to the parts, connections, electrical components and other directions of the connecting device, can solve the problem that the electrical connector cannot be separated reliably.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

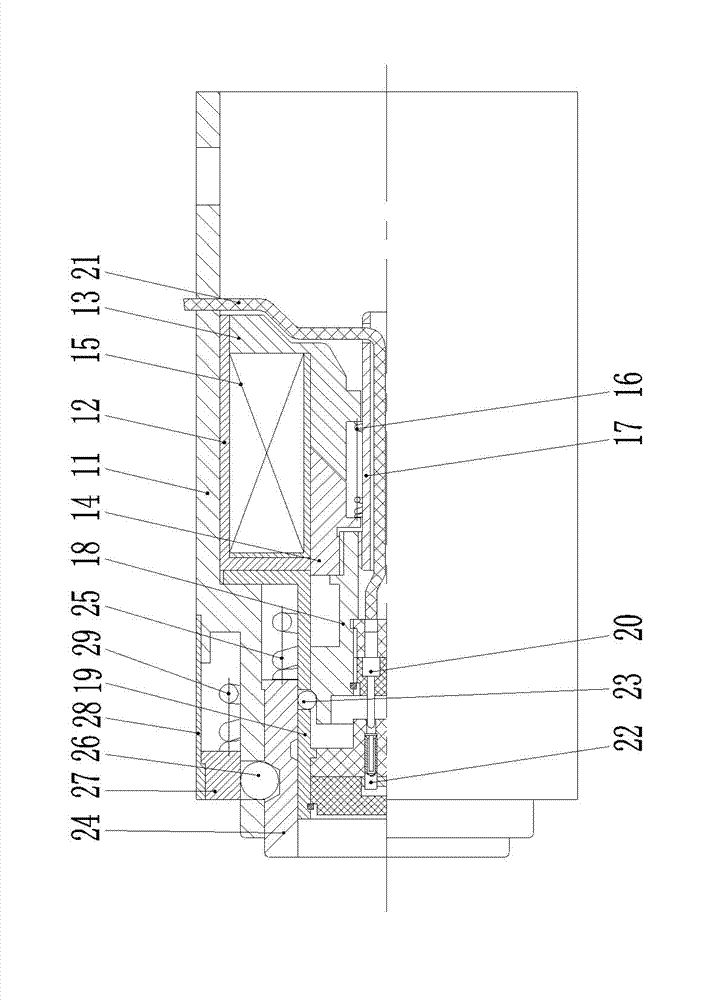

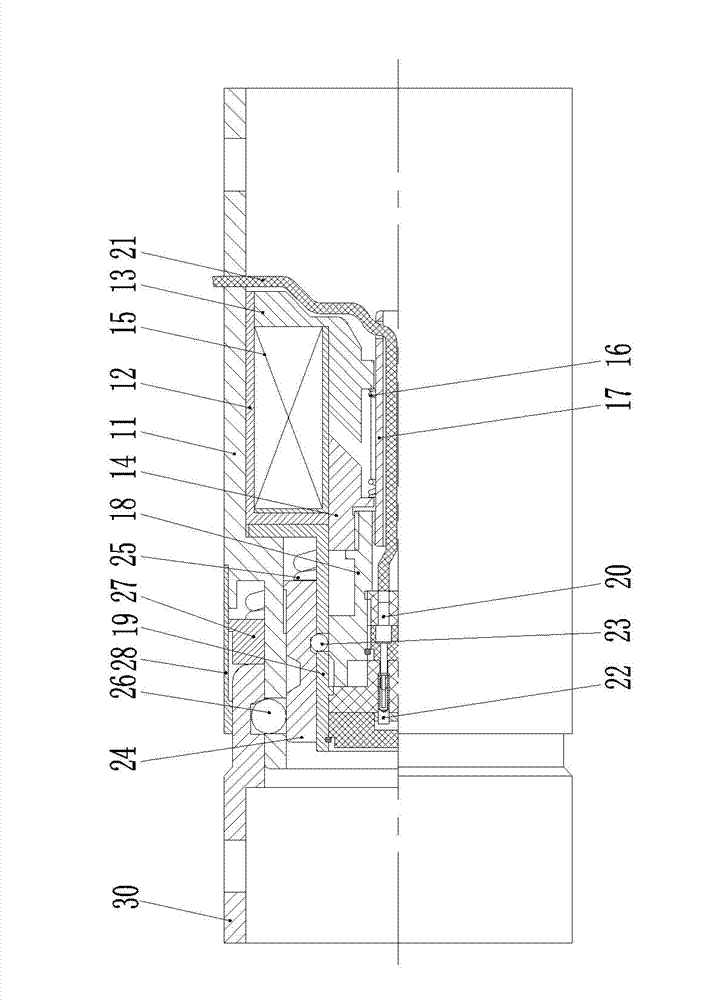

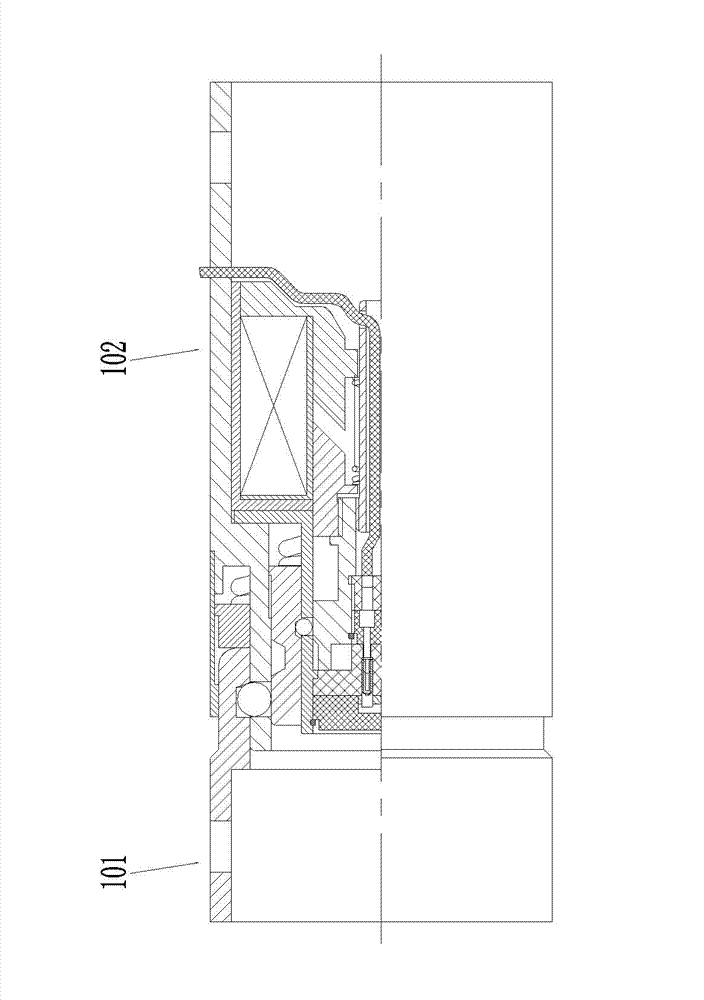

[0021] Embodiment 1 of the electromagnetic unlocking electrical connector of the present invention, such as Figure 1-2As shown, it includes housing 11, electromagnetic mechanism, center spring 16, wire inlet sleeve 17, center lock sleeve 18, seat cover 19, needle contact 20, wire 21, hole contact 22, inner steel ball 23, middle lock Cover 24, energy storage spring 25, outer layer steel ball 26, outer layer locking sleeve 27 and pushing spring 29. The housing 11 is in the shape of a stepped sleeve, including a small-diameter section at the front end and a large-diameter section at the rear end, and its inner hole also includes a small-diameter section at the front end and a large-diameter section at the rear end. The electromagnetic mechanism is fixedly assembled on the large-diameter section of the inner hole of the housing In the section, including the shell 12, the fixed armature 13 assembled in the shell 12, the movable armature 14, and the electromagnetic coil 15, the fix...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com