Anti-clogging type air blowing method liquid level gauge that can be used in polyester reactor

A technology of air blowing method and reactor, which is applied in the field of anti-blocking type air blowing method liquid level gauge, which can solve problems such as blockage and failure of air blowing liquid level gauge, and achieve the effect of expanding adaptability to occasions and improving reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

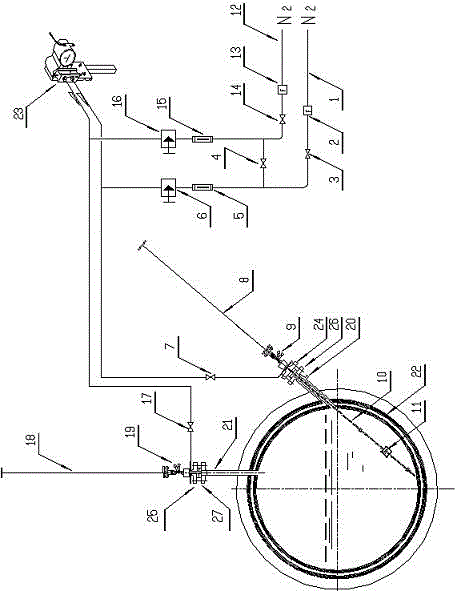

[0007] see figure 1 , the present invention provides a kind of anti-clogging type gas blowing liquid level gauge that can be used in polyester reactor, and it comprises the first bushing 20 and the second bushing 21 that are used to be installed on tank body 22, and described first The upper ends of the bushing and the second bushing are respectively connected with a first sealing ball valve 9 and a second sealing ball valve 19, and the upper ends of the first sealing ball valve and the second sealing ball valve are respectively equipped with a first stabbing device and a second stabbing device. Needle devices, the first needle device and the second device are respectively provided with a first needle 8 and a second needle 18 . The needle-throwing device can adopt any suitable form, which is used to install the needle and ensure that the needle can move axially and extend into the corresponding sleeve through the corresponding sealing ball valve, so that after opening the corr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com