Anti-jamming reducing cone drive mechanism

A technology of transmission mechanism and decompression cone, which is applied in the direction of transmission device, mechanical equipment, belt/chain/gear, etc., can solve problems such as blockage and ineffective decompression cone blockage, achieve broad market prospects, improve work efficiency, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The specific embodiment of the present invention is further described below in conjunction with accompanying drawing:

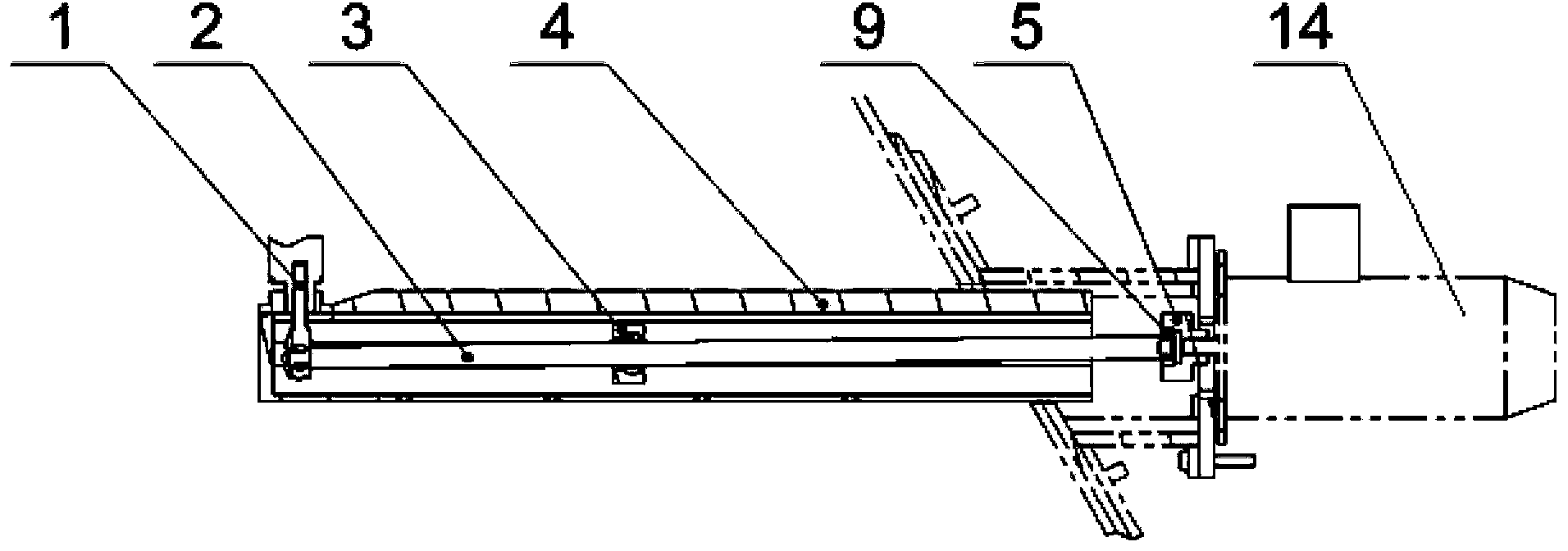

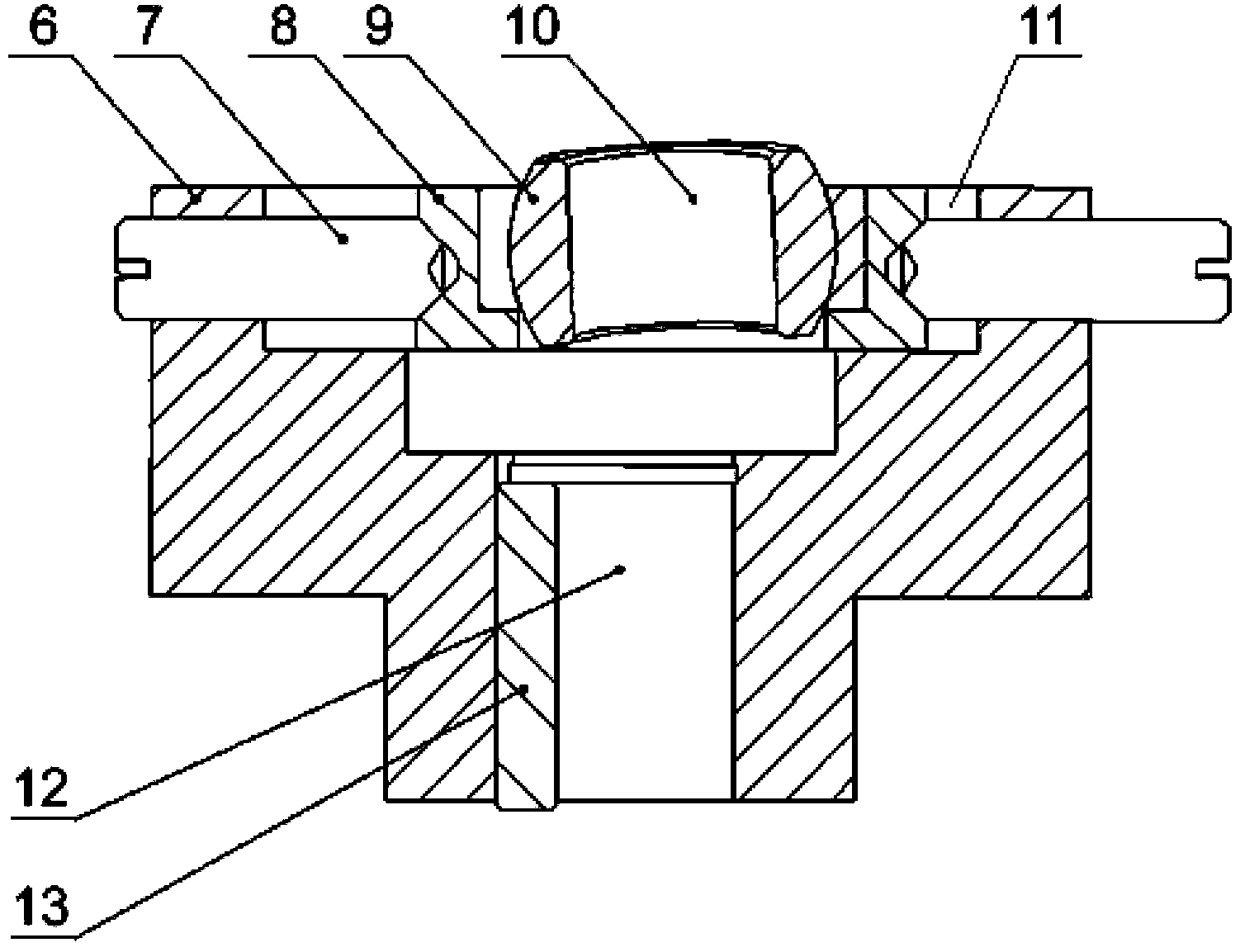

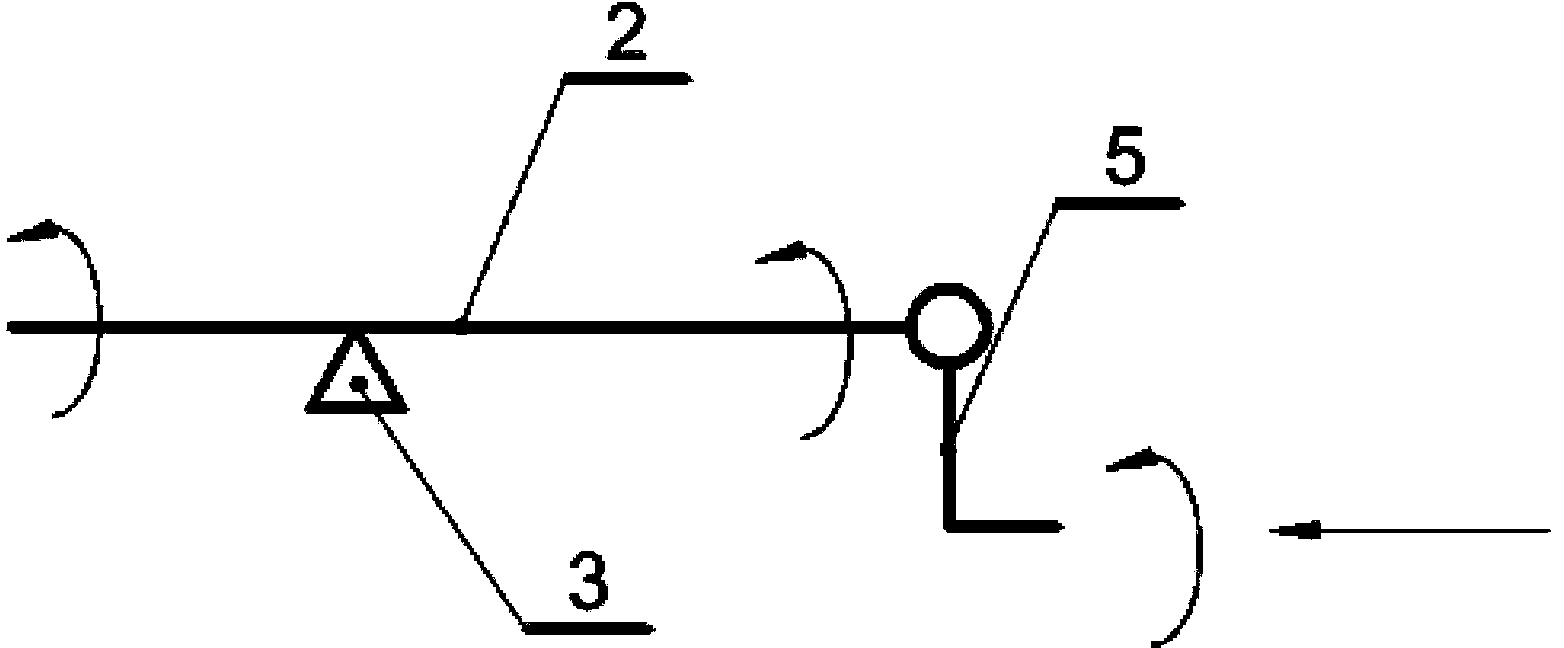

[0015] Such as figure 1 As shown, an anti-blocking decompression cone transmission mechanism of the present invention includes a transmission mechanism and a transmission box 4 composed of a rod end joint bearing 1, a swing rod 2, a movable fulcrum 3, and a converter 5. The converter 5 One end is connected with the motor 14, the other end is connected with one end of the swing rod 2, the other end of the swing rod 2 passes through the movable fulcrum 3 and is connected with the rod end joint bearing 1, and the rod end joint bearing 1 is connected with the connection part of the decompression cone The transmission mechanism is partially enclosed in the transmission box 4. The movable fulcrum 3 is composed of a support body and a self-aligning bearing. The split design can meet the needs of installation and dust prevention. Slide along the length direct...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com