Fiber grating strain sensor

A strain sensor, fiber grating technology, applied in instruments, optical devices, measuring devices, etc., can solve the problems of complex installation and small measurement range, and achieve the effect of not easy to fall off, small solder joints, and firm soldering

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in conjunction with the accompanying drawings, but they do not constitute a limitation to the present invention, but are only examples to make the advantages of the present invention more clear and easy to understand.

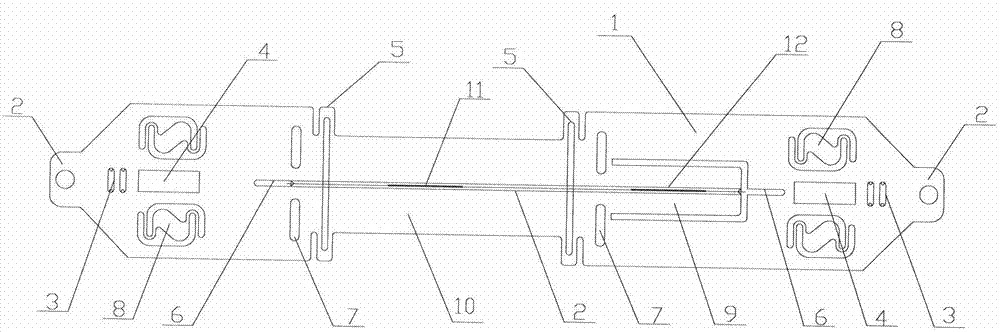

[0026] Such as figure 1 , 2, 3, 4 and 5, the proposed FBG strain sensor includes elastic strain gauge 1, FBG 11 and 12, armored sheath 14 and attachment 15. The elastic strain gauge 1 has a longitudinal axis and is symmetrical along the longitudinal axis, including a pair of symmetrical U-shaped beam elastic structures 5, a flat plate 10 connected to the U-shaped beam elastic structure 5, and a fiber grating 11 located on the longitudinal axis of the elastic strain gauge 1 and 12 thin slots 13, a pair of rectangular holes 6, temperature compensating means 9, fixing means 7, 8, armored sheath fixing means 2, 3, 4 positioned at the two ends of the thin slot 13 for passing pigtails; The device includes ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com