Buffering bolt sealing device for ball milling machine

A technology of sealing device and ball mill, which is applied in the direction of engine sealing, mechanical equipment, engine components, etc., can solve the problems of large impact of mill cylinder liner and liner bolts, impact on social environment, serious ash leakage, etc., to achieve Improvement of operation rate and effect of protecting social environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] In order to further understand the content, features, and effects of the present invention, the following embodiments are exemplified and described in detail with the accompanying drawings as follows:

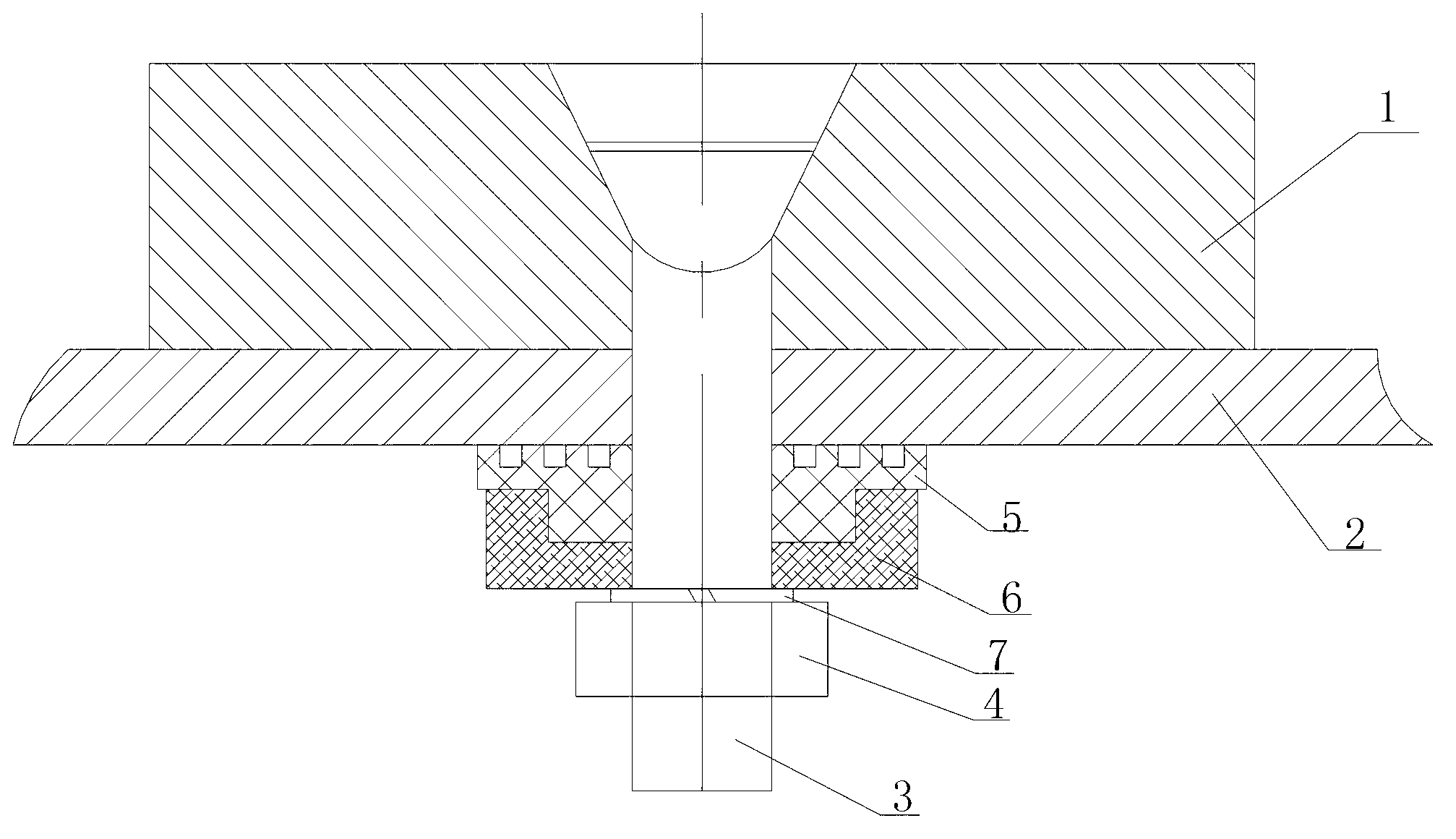

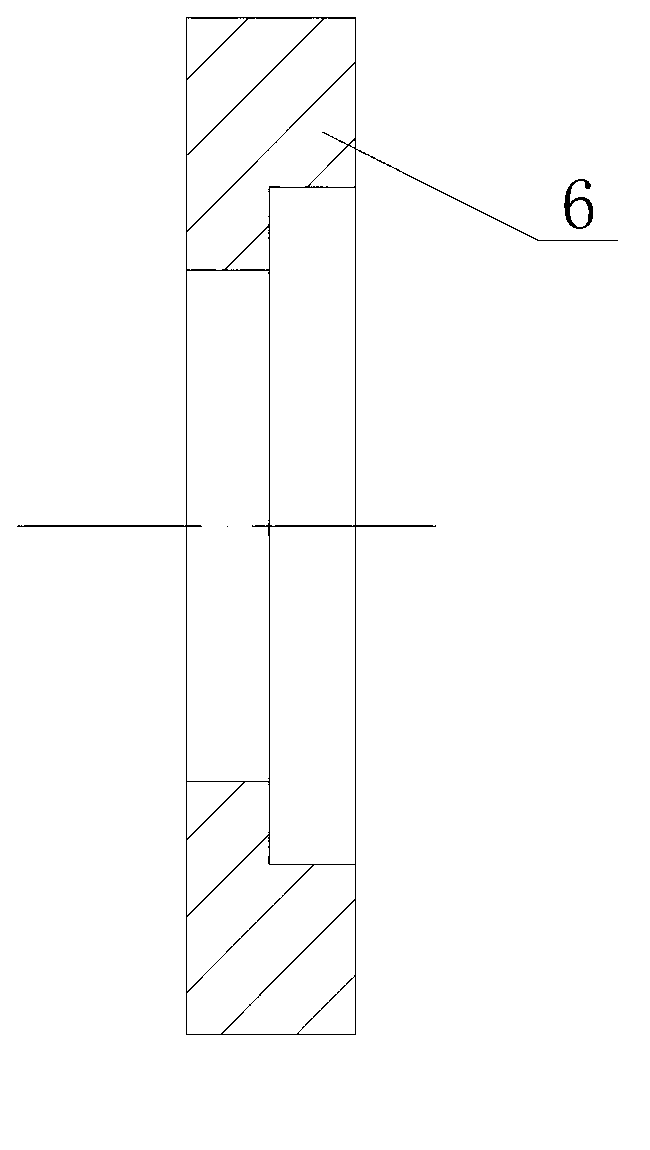

[0015] See Figure 1 to Figure 3 , A ball mill grinding bolt sealing device, comprising a mill liner 1 and a mill cylinder 2. The mill liner 1 and the mill cylinder 2 are connected by a grinding bolt 3, and the grinding bolts are equipped with pressure A tightening nut 4, the grinding bolt 3 on the lower surface of the mill barrel 2 is sleeved with a sealing ring 5, the sealing ring is made of fluorine rubber, and the lower surface of the sealing ring 5 is provided with a boss 5-1 , The apron gland 6 is sleeved on the boss, and the design of the boss structure ensures that the apron gland is evenly pressed when it is compressed. The lower surface of the apron gland 6 is provided with a spring pad 7. A compression nut 4 is installed on the skinned bolt 3 under the spring pa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com