Prestress pressure container

A pressure vessel, prestressing technology, used in pressure vessels, fixed-capacity gas storage tanks, mechanical equipment, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

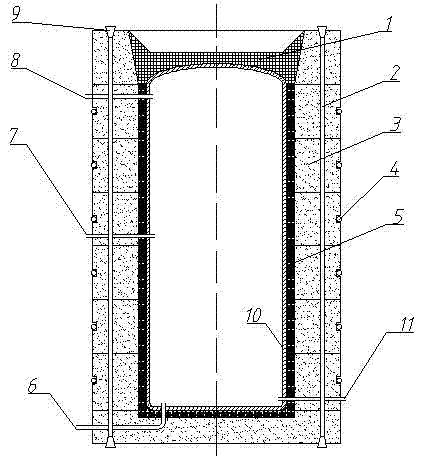

[0015] Below in conjunction with accompanying drawing this equipment is described in detail as follows:

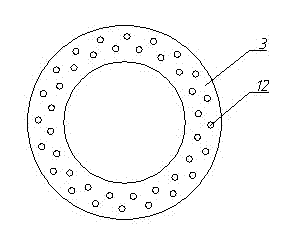

[0016] A prestressed pressure vessel, which is composed of axial prestressed tendons 2, circumferential prestressed tendons 4, prestressed concrete blocks 3, etc., and the detachable prestressed concrete blocks 3 The stress tendon 4 is fixed into a cylinder, and the inner wall of the prestressed concrete block 3 is provided with an insulating material layer 5. The inner wall of the insulating material layer 5 has a bushing 10, and the bushing 10 is used to hold the solution, and an end cap is arranged at the upper end of the container 1. The maintenance of the large container is facilitated, the middle, upper and bottom are provided with pipes leading to the outside of the container, and the middle pipe 7 and the upper pipe 8 can be used to enter and exit the solution. The prestressed concrete block 2 is provided with a plurality of axial prefabricated holes 12 in the axia...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com