Underground two-fluid grouting device

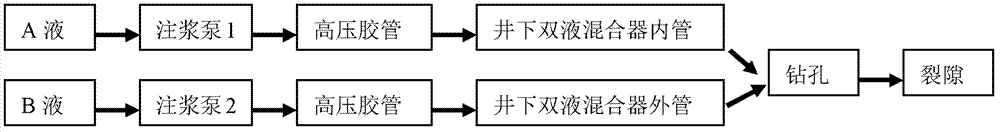

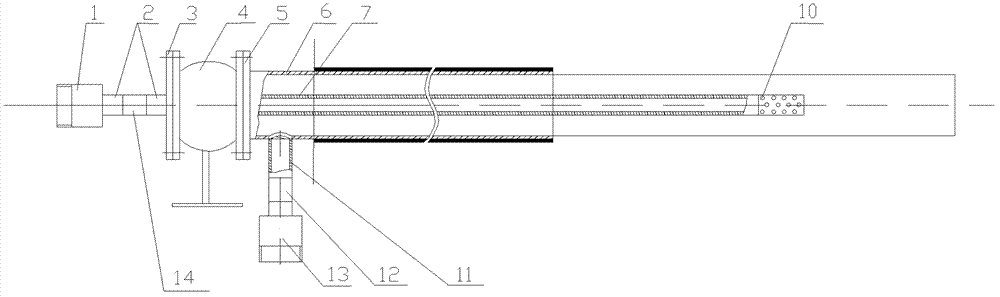

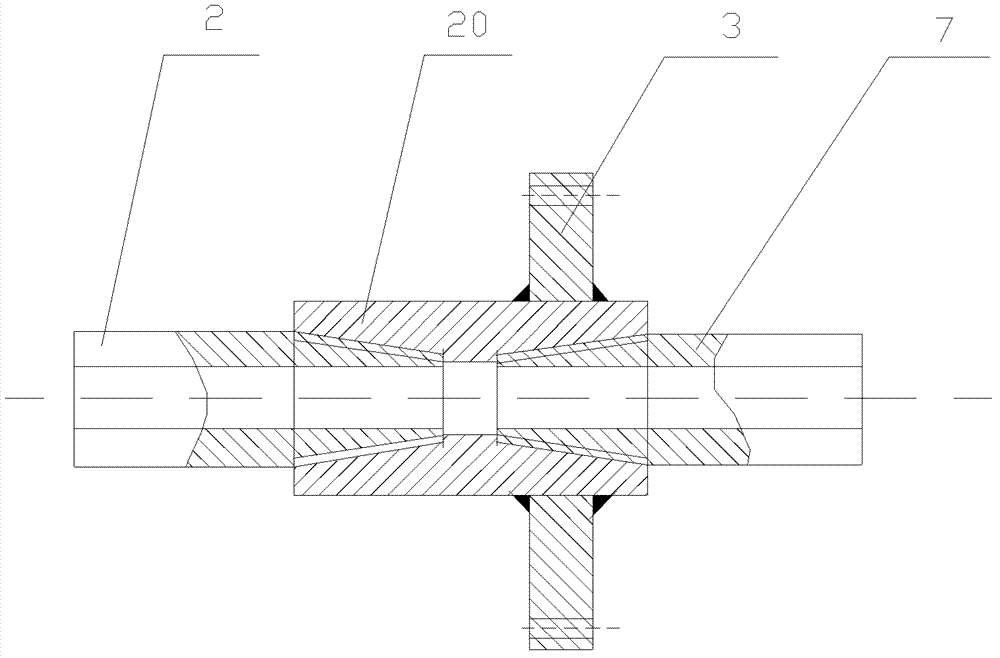

A dual-liquid grouting and grouting technology, which is used in vertical shaft equipment, wellbore lining, underground chambers, etc., can solve the problems of difficult maintenance and repair, poor grouting effect, complicated pipeline connections, etc., to eliminate the slurry plugging holes. , Good grouting effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

[0098] The on-site solidification test of cement-water glass (C-S) two-liquid ratio is described as follows:

[0099] It is difficult to use the traditional two-liquid grouting process in the treatment of water inflow in the second auxiliary road of Xinjulong Mining Co., Ltd. Because the grouting holes for construction are relatively deep (most of the holes are more than 60m), when the traditional two-liquid grouting process is used for grouting, the mixed slurry has not had time to enter the water-conducting fractures in the drilling holes. The phenomenon of solidification occurs, which leads to the plugging accident during grouting. According to the characteristics of water gushing in the second main road, the cement-water glass slurry was selected, and the proportioning test under normal temperature (25℃) was not only carried out on site. The temperature environment was also expanded, the setting time and strength of cement water glass at different temperatures of 35℃ and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com