Method for preparing polyvinyl chloride product from waste carbon paste produced by plasticizer production

A production process and technology of polyvinyl chloride, applied in the field of preparing polyvinyl chloride (PVC) products, can solve problems such as environmental pollution, and achieve the effect of reducing cost and consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] Example 1: A processing method for 95-degree grade PVC cable materials, including batching, kneading, mixing and compression molding, etc. In these steps, except that the batching has been improved, the remaining steps and corresponding process conditions are the same current technology.

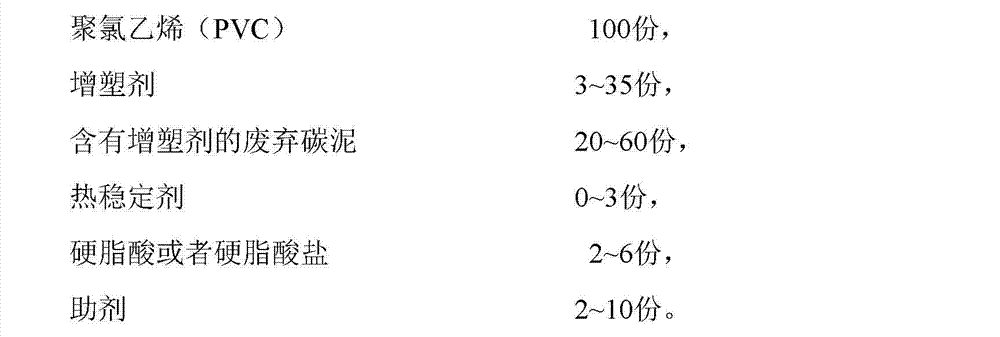

[0033] The batching is: the raw material is composed of the following ingredients in parts by weight:

[0034]

[0035]After testing, in the above waste carbon mud containing plasticizer, the weight content of TOTM is about 40%, the weight content of activated carbon is about 58%, and the weight content of refined additive is about 2%. Refined additives mainly refer to diatomaceous earth, aluminum oxide, kaolin, magnesium oxide, white clay, etc.

[0036] TOTM, ie, tris(2-ethyl)hexyl trimellitate.

[0037] The organotin heat stabilizer, for example, can be selected from the HTM-2010 methyl tin heat stabilizer in the HTM series of Zhejiang Hepton New Materials Co., Ltd.

[0038] P...

Embodiment 2

[0042] Example 2: A processing method for 105-degree PVC ordinary sheathed cable materials, including batching, kneading, mixing and compression molding, etc., in these steps, except that the batching has been improved, the remaining steps and corresponding processes Conditions are all the same as the prior art.

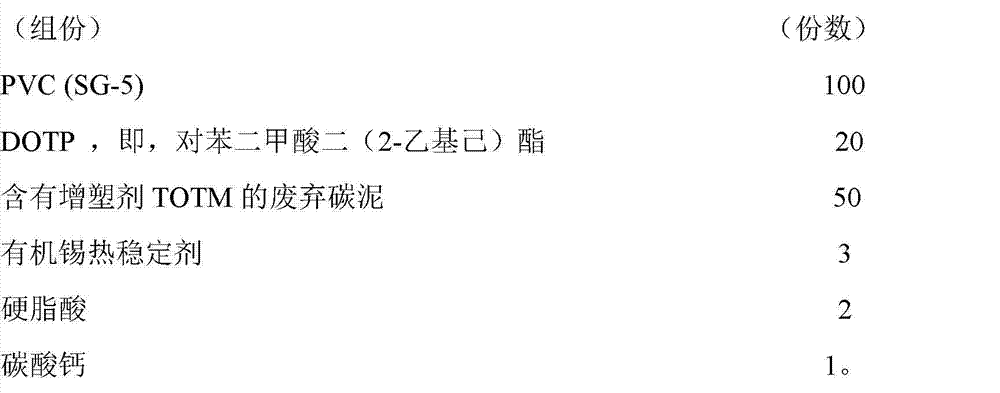

[0043] The batching is: the raw material is composed of the following ingredients in parts by weight:

[0044]

[0045] The calcium-zinc composite heat stabilizer can be selected from the HCZ-1086 calcium-zinc composite heat stabilizer in the HCZ series of Zhejiang Hypton New Materials Co., Ltd.

[0046] The waste carbon mud that contains plasticizer TOTM is the same as embodiment 1.

[0047] Its main performance parameters are described in Table 2 below:

[0048] Table 2. Main performance indicators of 105-degree PVC ordinary sheath cable material

[0049] project name

Embodiment 3

[0050] Embodiment 3: A kind of processing method of dark PVC sole material, comprises batching, kneading, kneading and pressing molding etc., in these steps, except that batching has been improved, all the other steps and corresponding technological conditions are all the same as prior art .

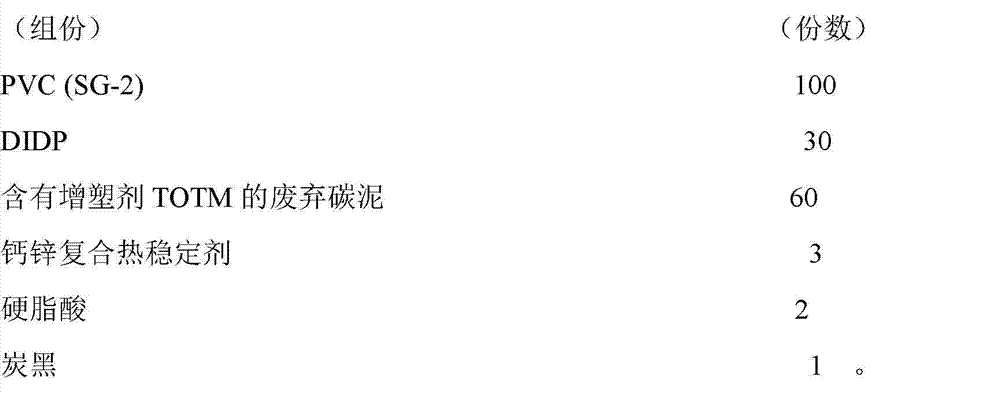

[0051] The batching is: the raw material is composed of the following ingredients in parts by weight:

[0052]

[0053] In the above-mentioned waste carbon mud containing DOP, the weight content of DOP is about 45%, the weight content of activated carbon is 52%, and the weight content of refined adhering agent is about 3%.

[0054] Its performance parameters are shown in Table 3 below:

[0055] table 3

[0056] project name

PUM

| Property | Measurement | Unit |

|---|---|---|

| time | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

| thermal deformation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com