Preparation method of cationic styrene-acrylic microemulsion

A cationic, microemulsion technology, applied in the field of new materials, can solve the problems of low monomer conversion rate, high gel content, poor emulsion stability, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

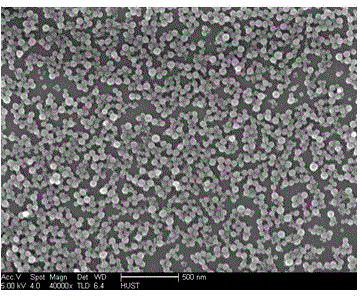

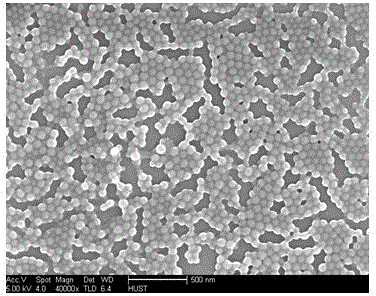

Image

Examples

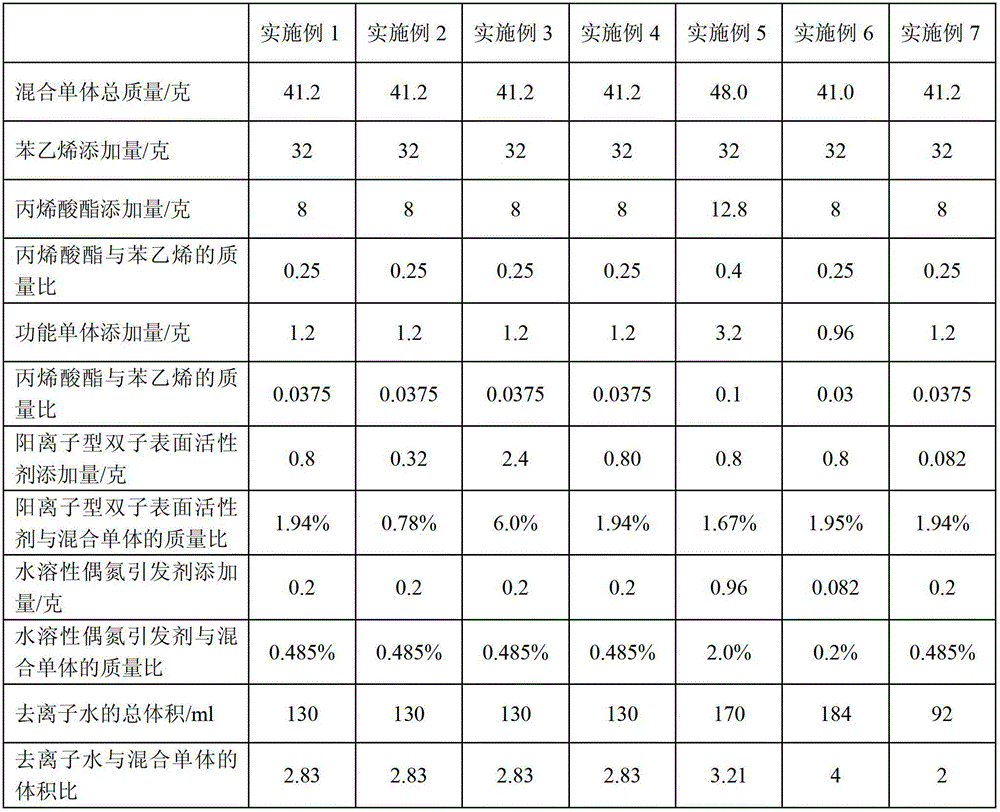

Embodiment 1

[0024] In a 250mL three-necked flask, add 30ml of deionized water and 0.08g of G16-6-G16 cationic gemini surfactant (accounting for 10wt% of the total amount of surfactants), stir under nitrogen protection, and dropwise add 30.4g of styrene, A mixed monomer of 7.6 grams of butyl acrylate and 1.14 grams of acrylic acid (accounting for 95 wt% of the total amount of monomers), after the monomers were added dropwise in 30 minutes, was stirred and mixed uniformly to obtain a styrene-acrylic pre-emulsion.

[0025] Add 90ml of deionized water, 0.72g of G16-6-G16 cationic gemini surfactant (accounting for 90wt% of the total amount of surfactants), 0.1g of azobisisobutyl Amidine hydrochloride initiator (accounting for 50wt% of the total amount of initiators), under the protection of nitrogen, the stirring rate is controlled at 250rpm, after the temperature is raised to 70°C, 1.6 grams of styrene, 0.4 grams of butyl acrylate, and 0.06 grams of acrylic acid are added. (accounting for 5wt...

Embodiment 2

[0027] In a 250mL three-neck flask, add 30ml of deionized water and 0.03g of G16-6-G16 cationic gemini surfactant (accounting for 9.4wt% of the total amount of surfactants), stir under nitrogen protection, and add 30.4g of styrene dropwise , 7.6 grams of butyl acrylate, 1.14 grams of mixed monomers of acrylic acid (accounting for 95wt% of the total amount of monomers), after the monomers were added dropwise in 30 minutes, they were stirred and mixed uniformly to obtain a styrene-acrylic pre-emulsion.

[0028]Add 90ml of deionized water, 0.29g of G16-6-G16 cationic gemini surfactant (accounting for 90.6wt% of the total amount of surfactants), 0.1g of azobisiso Butyamidine hydrochloride initiator (accounting for 50wt% of the total amount of initiators), under the protection of nitrogen, the stirring rate is controlled at 250rpm. After the temperature is raised to 70°C, a mixture of 1.6 grams of styrene, 0.4 grams of butyl acrylate and 0.06 grams of acrylic acid is added. Monomer...

Embodiment 3

[0030] In a 250mL three-necked flask, add 30ml of deionized water and 0.48g of G16-3-G16 cationic gemini surfactant (accounting for 20wt% of the total amount of surfactants), stir under nitrogen protection, and dropwise add 28.8g of styrene, A mixed monomer of 7.2 grams of butyl acrylate and 1.08 grams of methacrylic acid (accounting for 90 wt% of the total amount of monomers), after the monomers were added dropwise in 30 minutes, was stirred and mixed uniformly to obtain a styrene-acrylic pre-emulsion.

[0031] Add 90ml of deionized water, 1.92g of G16-3-G16 cationic gemini surfactant (accounting for 80wt% of the total amount of surfactants), 0.1g of azobisisobutyl Imidazoline hydrochloride initiator (accounting for 50wt% of the total amount of initiators), under the protection of nitrogen, the stirring rate is controlled at 250rpm, and after the temperature is raised to 70°C, add 3.2 grams of styrene, 0.8 grams of butyl acrylate, and 0.12 grams of methacrylic acid The mixed ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com