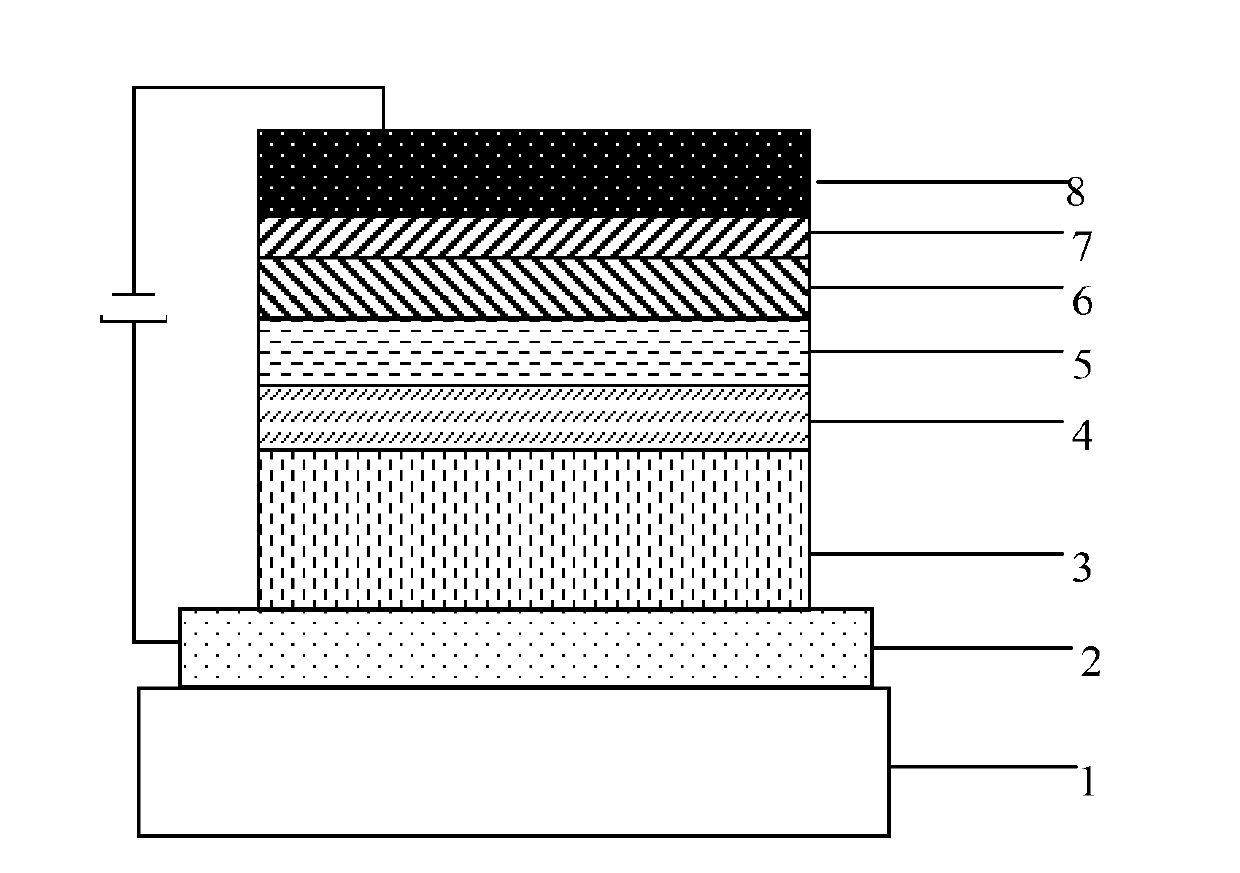

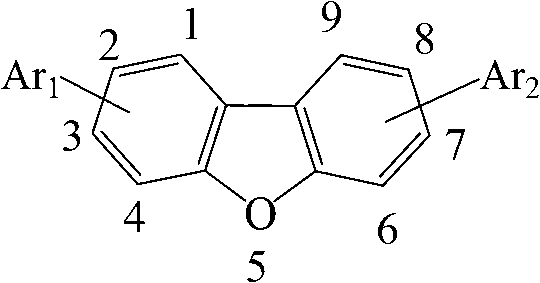

Derivative compound treating dibenzofuran as core framework, and its application in OLED (organic light emission diode)

A technology of dibenzofuran and compound, which is applied in the field of derivative compounds, can solve the problem of inability to produce high-performance light-emitting devices, and achieve the effect of increasing driving life, improving efficiency and life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

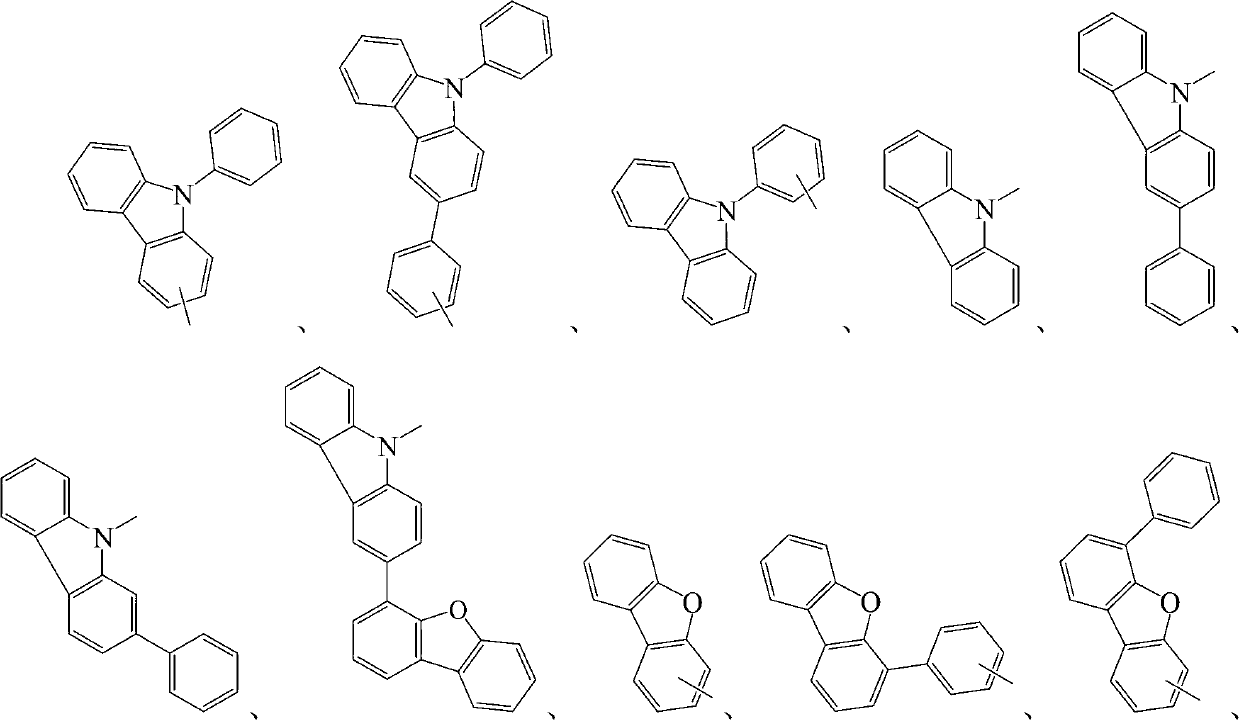

[0063] Synthesis of 2,8-bis(N,N-biphenylamino)dibenzofuran

[0064]

[0065] 100 ml four-necked bottle under nitrogen protection, add about 1.99 g of raw material 1, about 4.3 g of raw material 2, 1.3 g of sodium tert-butoxide, Pd 2 (dba) 3 0.2 g, P(t-Bu) 3 0.5 milliliters, 70 milliliters of solvent toluene, heat up to reflux, reflux temperature 115 degrees, reflux for one hour, point plate detection, the reaction is complete, turn off the heating, cool the reaction solution and spin dry, the spin-dried solids are washed twice with 50 ml water respectively , filtered, washed twice with 50ml water, filtered, the filter cake was washed twice with 50ml ethanol, filtered, and the filter cake was dried to obtain 5.9 grams of crude product, yield 98%, crude product purity 89.79%.

[0066] The above crude material was passed through a silica gel column, the eluent ratio was petroleum ether:dichloromethane=5:1, and after sublimation and purification, a product with a purity of 99...

Embodiment 2

[0074] 2,8-bis(4-dibenzofuryl)dibenzofuran

[0075]

[0076] 100 ml of four-necked bottle under nitrogen protection, sequentially add about 1.63 g of raw material 1, about 2.33 g of raw material 2, 0.15 g of catalyst tetrakis(triphenylphosphine) palladium, 2.4 g of sodium carbonate, 25 ml of solvent toluene, ethanol, and water each, and heat up To reflux, the reflux temperature is 80 degrees, reflux for three hours, spot the plate, the raw materials are basically reacted completely, turn off the heating, cool naturally, filter after cooling, and wash the filter cake twice with 30ml water and twice with 30ml ethanol. The filter cake was dried to obtain about 2 grams of off-white solid, with a yield of 80% and a purity of 94.87%. The above crude material was passed through a silica gel column, the eluent ratio was petroleum ether:dichloromethane=3:1, and after sublimation and purification, a product with a purity of 99.87% was obtained. The product was used for chemical analy...

Embodiment 3

[0084] 2,8-bis((3,5-diphenyl)phenyl)dibenzofuran

[0085]

[0086] 100 ml four-necked bottle under nitrogen protection, add about 0.52 g of raw material 1, about 0.97 g of raw material 2, 0.05 g of tetrakis(triphenylphosphine) palladium, 0.77 g of sodium carbonate, solvent toluene, ethanol, water, 10 ml each, and heat up To reflux, the reflux temperature is 79 degrees, and after 12 hours of reflux, the board is spotted. The raw material 1 has reacted completely, but there are three product spots, indicating that there may be intermediate products. Add 0.05 grams of catalyst, and then reflux for 12 hours, and the board is tested. Basically After the reaction was complete, turn off the heating, filter after cooling, wash the filter cake twice with 10 ml of water and twice with 10 ml of ethanol, and dry the filter cake to obtain about 0.88 g of a gray solid with a crude yield of 88% and a purity of 90%. The above crude material was passed through a silica gel column, the eluen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com