Method for preparing WO3 film

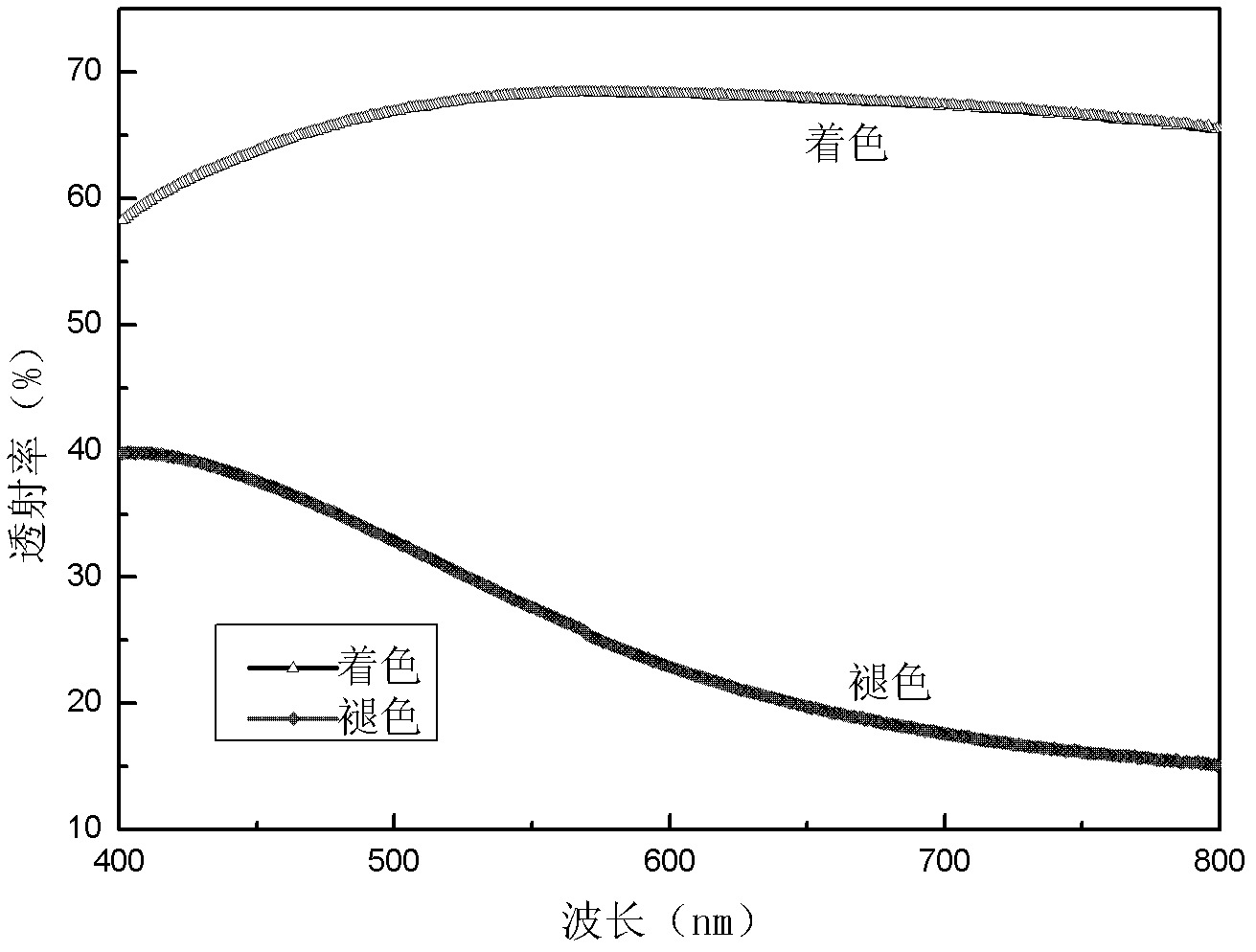

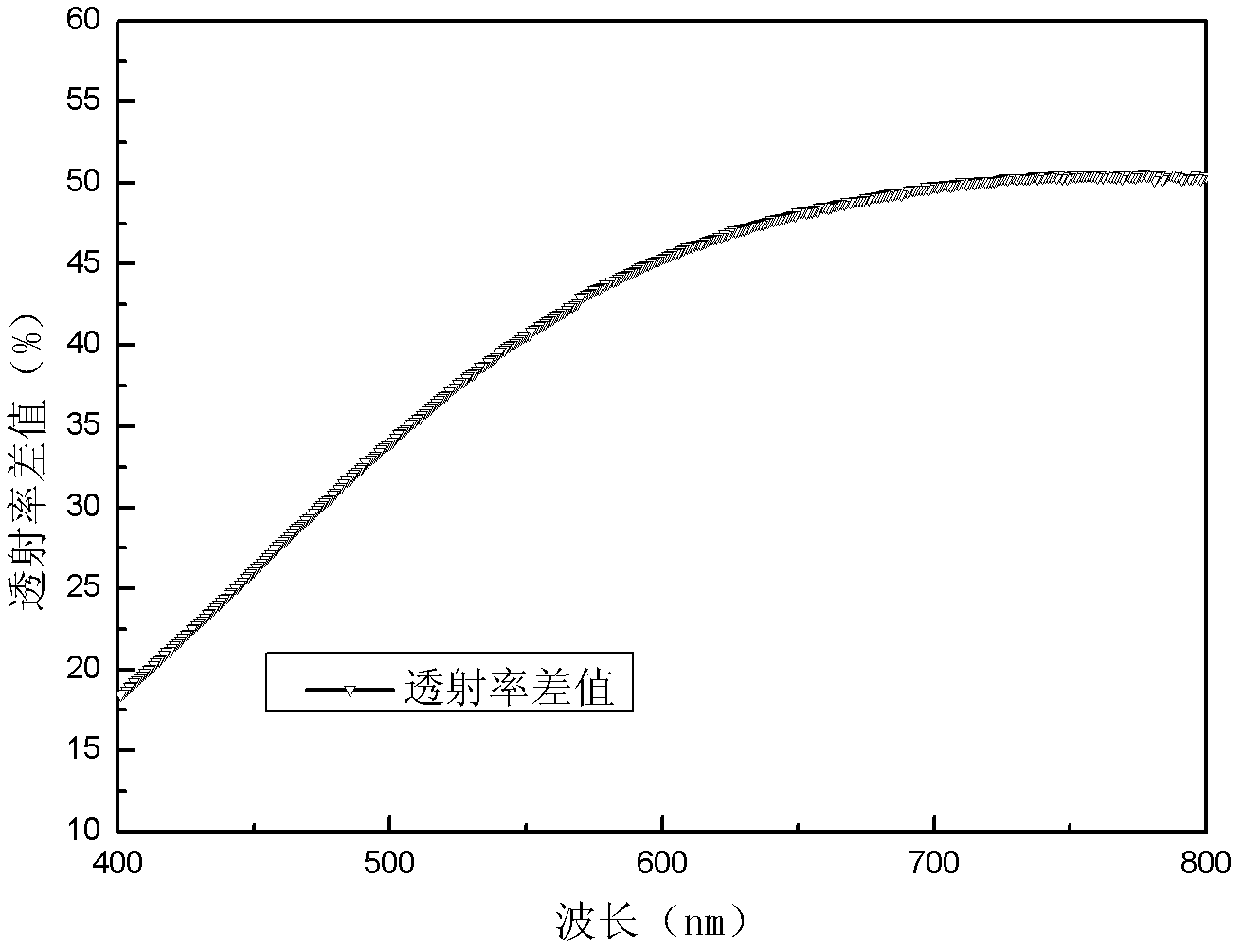

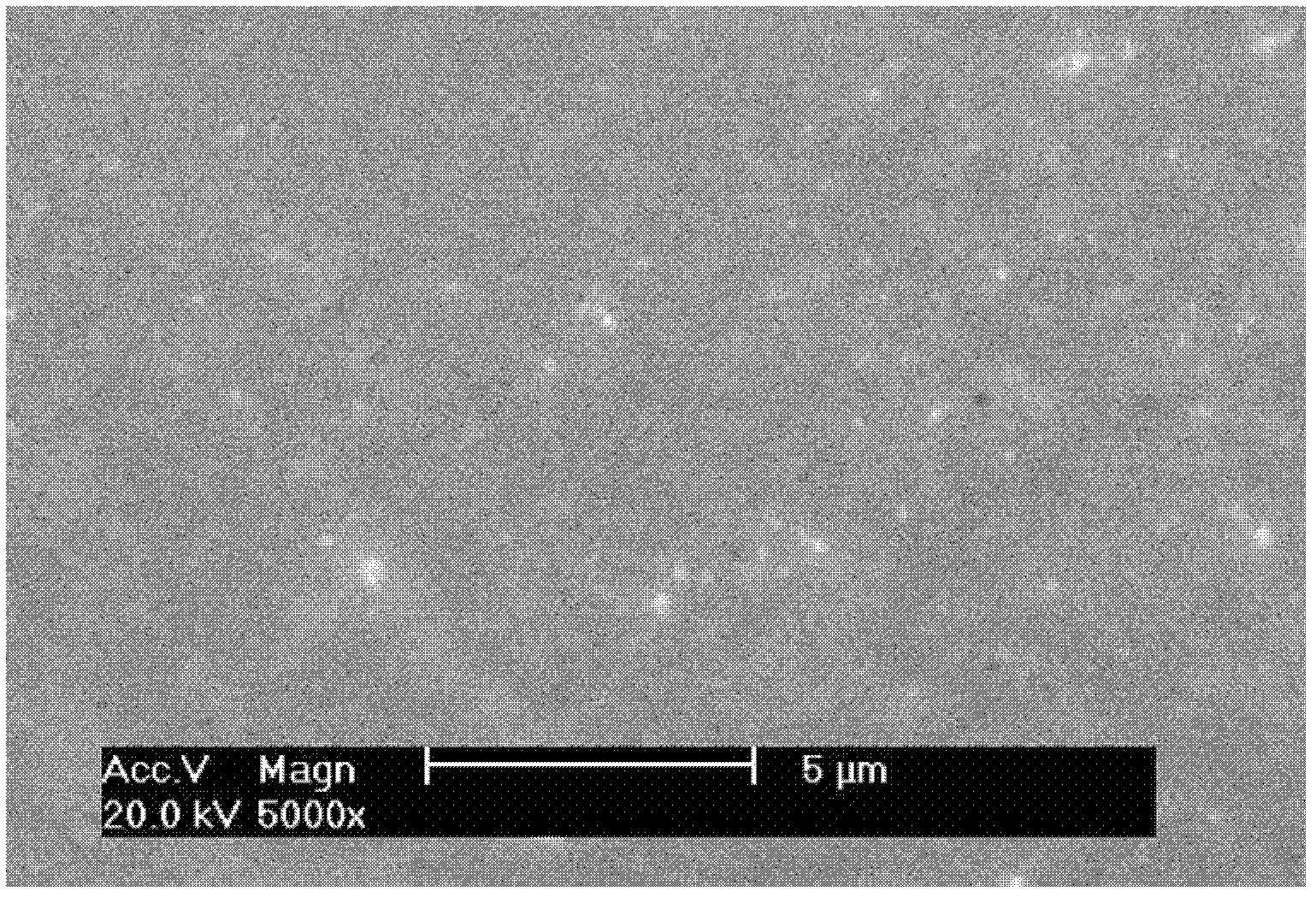

A technology of thin film and tungsten powder, which is applied in the field of preparing WO3 thin film, can solve the problems of complex preparation process, high cost of alkoxide, unstable sol, etc., and achieve the effect of simple process, smooth and dense surface, and good electrochromic performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] A kind of WO 3 Film formulation and preparation of WO according to the formulation 3 A thin film method comprising the steps of:

[0026] (1) Weigh 18.85g of tungsten powder, take a small amount of tungsten powder and slowly add it to 100ml of hydrogen peroxide, the violent reaction will generate air bubbles, keep stirring with a glass rod to dissipate heat; when the reaction in the solution gradually weakens, continue to add a small amount of tungsten powder into the hydrogen peroxide. Repeat the above operations until the solution no longer produces violent reactions and there are fewer bubbles in the solution. (2) The solution obtained in step (1) was stirred and reacted at 51° C. for 26 minutes in order to completely react the hydrogen peroxide, and then the solution was filtered. (3) Add 50ml of absolute ethanol to the filtrate of step (2), then stir and heat at 80°C for 28min. The orange clear sol was left to stand for 4 hours. (4) The ITO glass substrate was ...

Embodiment 2

[0028] A kind of WO 3 Film formulation and preparation of WO according to the formulation 3 A thin film method comprising the steps of:

[0029] (1) Weigh 24.75g of tungsten powder, take a small amount of tungsten powder and slowly add it to 200ml of hydrogen peroxide, the violent reaction will generate air bubbles, keep stirring with a glass rod to dissipate heat; when the reaction in the solution gradually weakens, continue to add a small amount of tungsten powder into the hydrogen peroxide. Repeat the above operations until the solution no longer produces violent reactions and there are fewer bubbles in the solution. (2) The solution obtained in step (1) was stirred and reacted at 51° C. for 30 minutes, in order to completely react the hydrogen peroxide, and then filter the solution. (3) Add 100ml of absolute ethanol to the filtrate of step (2), then stir and heat at 80°C for 30min. The orange transparent sol was left to stand for 5 hours. (4) The ITO glass substrate wa...

Embodiment 3

[0031] A kind of WO 3 Film formulation and preparation of WO according to the formulation 3 A thin film method comprising the steps of:

[0032] (1) Weigh 25.00g of tungsten powder, take a small amount of tungsten powder and slowly add it to 100ml of hydrogen peroxide, the violent reaction will generate air bubbles, keep stirring with a glass rod to dissipate heat; when the reaction in the solution gradually weakens, continue to add a small amount of tungsten powder into the hydrogen peroxide. Repeat the above operations until the solution no longer produces violent reactions and there are fewer bubbles in the solution. (2) The solution obtained in step (1) was stirred and reacted at 55° C. for 26 minutes in order to completely react the hydrogen peroxide, and then the solution was filtered. (3) Add 45ml of absolute ethanol to the filtrate of step (2), then stir and heat at 75°C for 30min. The orange clear sol was left to stand for 4 hours. (4) The ITO glass substrate was ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com