Inclined core-pulling mechanism of plastic injection mold

An injection mold and oblique core-pulling technology, which is applied in the fields of injection mold oblique core-pulling mechanism and injection mold opening mechanism, can solve the problems that the inclined top mechanism cannot solve the problem of smooth product ejection, affecting the quality of injection molding products, and low production efficiency. Achieving good economic benefits, simple structure, and quality assurance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

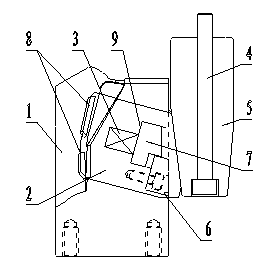

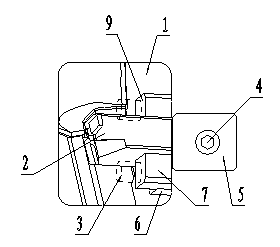

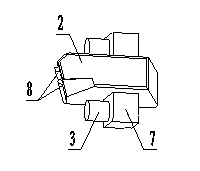

[0018] See Figure 1, Figure 2, image 3 , the present invention includes a movable mold insert 1, an inclined slider 2, a wedge-shaped pressing block 5 and a slider limiter 6, the movable mold insert 1 is fixed on the movable template by screws, and it is provided with an injection molding cavity and A cavity for the inclined core-pulling mechanism, the inclined slider 2 is located in the cavity of the movable mold insert 1, and a lateral core 8 matching the injection molding workpiece is arranged on its top end, and the tail of the inclined slider is a wedge-shaped surface structure, Both sides of the oblique slider are provided with stoppers 7, the upper end of the stopper 7 is equipped with a compression spring 3, and the bottom surface of the stopper 7 is matched with the slider limiter 6; It is fixed on the fixed plate of the injection mold, and the wedge-shaped pressing surface at the lower half matches the wedge-shaped surface at the tail of the inclined slider; the sli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com