Trimming, flanging and side punching compound die

A composite mold, side punching technology, applied in forming tools, manufacturing tools, metal processing equipment, etc., can solve problems such as positioning deviation, affecting product quality, and large vibration and impact, avoiding excessive contact or collision, and improving inspection judgment. The effect of high speed and workpiece machining accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be described in detail below in conjunction with accompanying drawings and specific preferred embodiments, so that the advantages and features of the present invention can be more easily understood by those skilled in the art. range is limited.

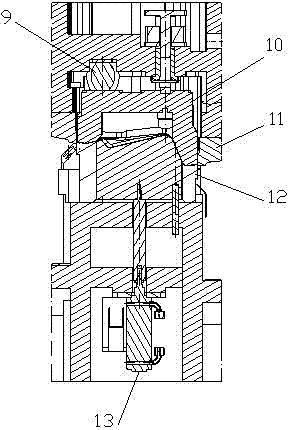

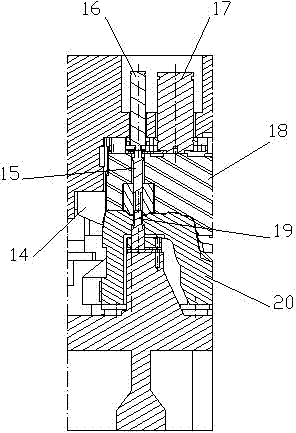

[0024] see Figure 1 to Figure 6 , the trimming and flanging side punching composite mold of the present invention comprises: upper mold 1 and lower mold 2, described upper mold 1 is positioned at described lower mold 2 top, and described upper mold 1 is provided with a plurality of guide sleeves 31, trimming Upper die 3, flanging upper die 4 and side punching upper die 5, described lower die 2 is provided with a plurality of guide pillars 30, a plurality of stop blocks 25, a plurality of nitrogen springs 26, a plurality of wear plates 27, repair Limit lower die 6, flanging lower die 7 and side punching lower die 8, described trimming upper die 3 is provided with Youli glue 9, binder plate 10 and upp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com