Fluidized bed powder dipping robot

A technology of fluidized bed and manipulator, which is applied in the direction of manipulator, program control manipulator, and device for coating liquid on the surface. The effect of dust and smooth appearance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

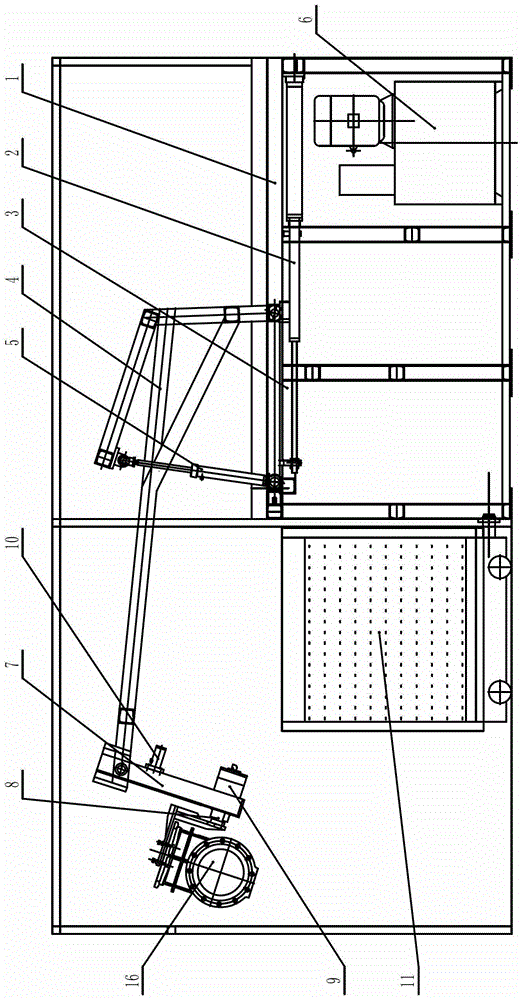

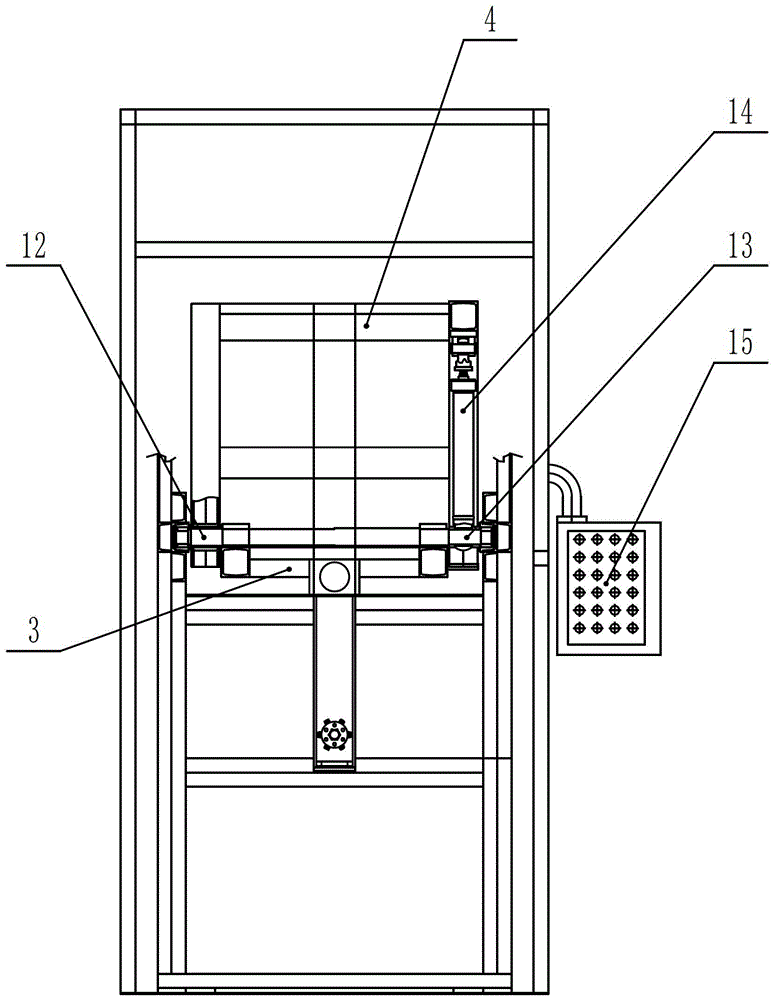

[0023] Such as figure 1 Shown, a kind of fluidized bed powder dipping manipulator comprises frame assembly 1, is provided with multistage oil cylinder 2 below frame assembly 1, and the cylinder body of multistage oil cylinder 2 is fixed on the frame assembly 1; Mobile support 3 is located at On the frame assembly 1; the piston rod of the multi-stage oil cylinder 2 is hinged with the mobile bracket 3; the end of the pendulum assembly 4 is hinged on the mobile bracket 3; the cylinder body of the lifting cylinder 5 is connected with the mobile bracket 3, and the lifting cylinder The piston rod of 5 is connected to the middle part of the swing frame assembly 4; a hydraulic system 6 is provided under the frame assembly 1, and the multi-stage oil cylinder 2 and the lifting cylinder 5 are connected to the hydraulic system 6 through pipelines; The top is equipped with a rotating headstock assembly 7, and the end of the rotating headstock assembly 7 is provided with a fixture assembly ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com