Pressure tester for detecting compression performance of valve

A pressure testing machine and performance technology, which is applied in the testing of mechanical components, testing of machine/structural components, and by measuring the rate of increase and deceleration of fluids, etc., can solve the problems of low comprehensive utilization of machine parts, limited valve specifications, and valve sideslip Sealing and other issues to achieve the effect of improving test efficiency, avoiding lateral offset, and stable force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

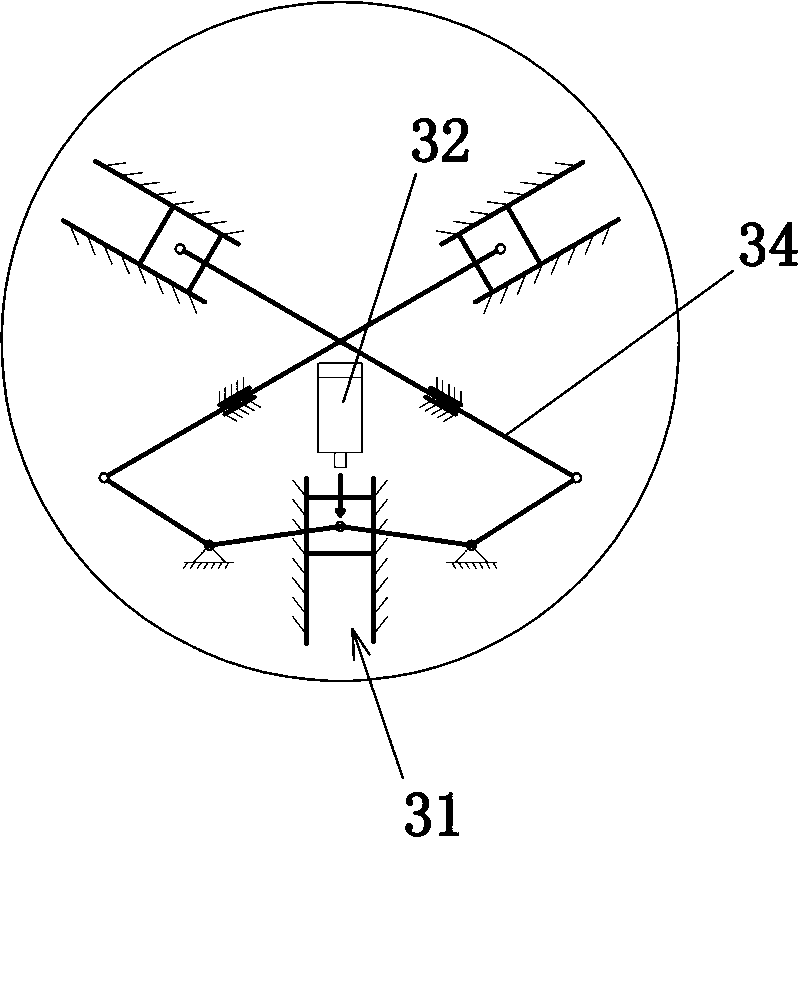

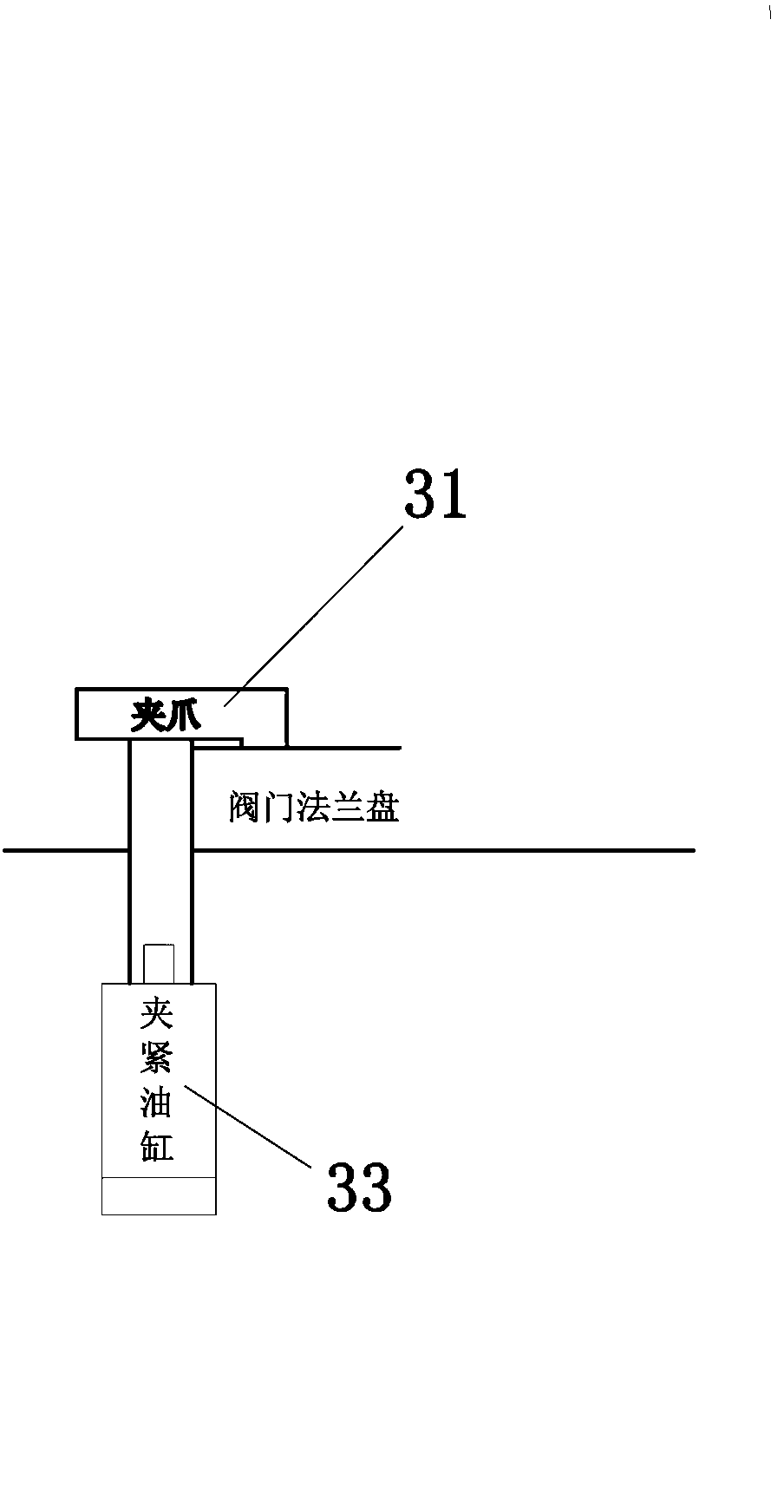

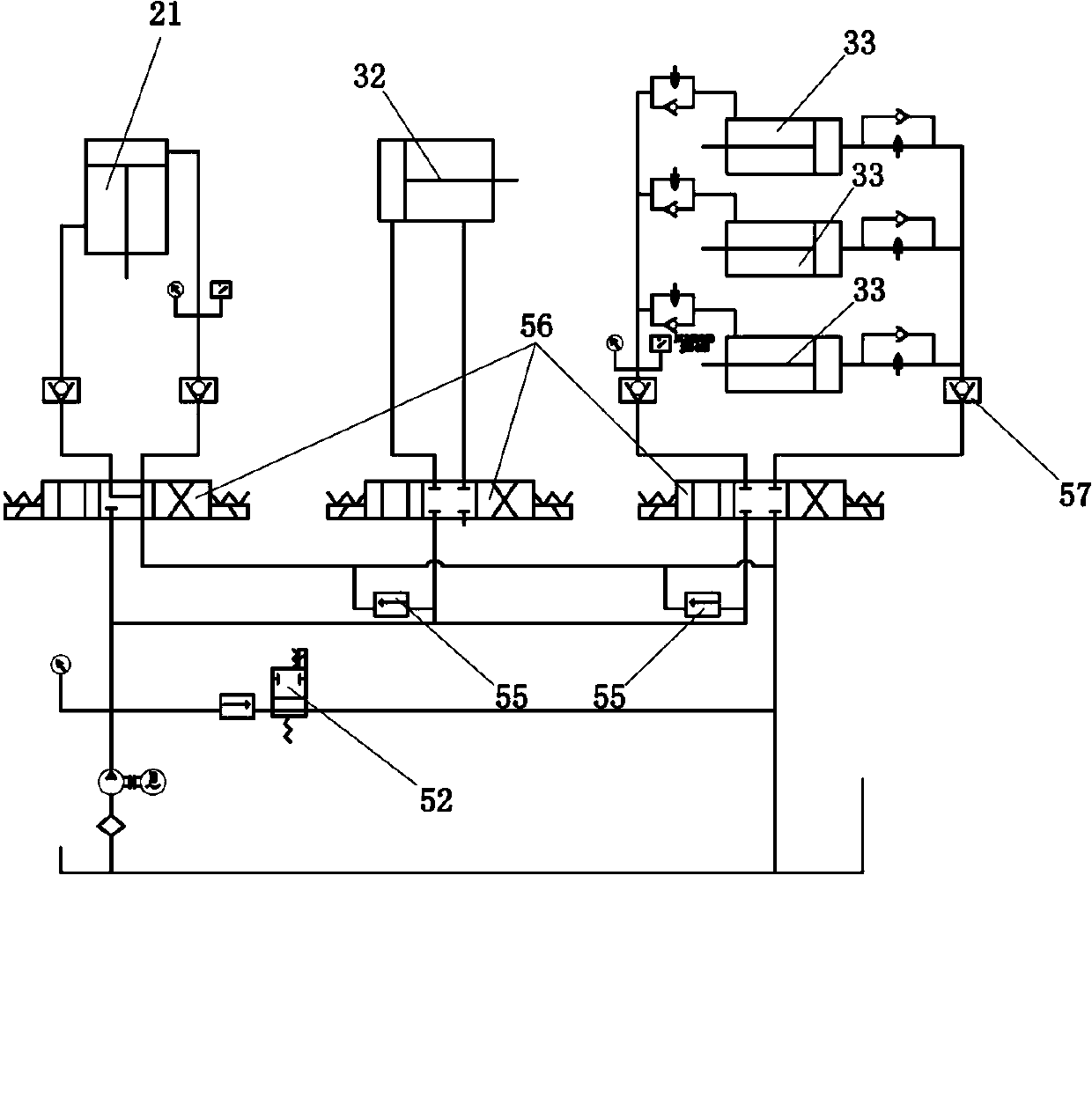

[0030] Refer to attached figure 1 , figure 2 , image 3 , Figure 4 with Figure 5 . A pressure testing machine for testing the pressure performance of valves, including a control console 1, a top-pressure test bench 2, a gripper-type test bench 3, and a supply medium that cooperates with the top-pressure test bench 2 and the gripper-type test bench 3 respectively Pressure device and oil pressure driving device 5, the supply medium pressure device is a water supply pressure device 4, and the water supply pressure device 4 and oil pressure driving device 5 are all controlled by the console 1. The jaw-type test bench 3 includes a jaw test bench 30, an active gripper 31 installed on the gripper test bench 30, and two driven grippers (not shown in the figure) that act synchronously with the active gripper 31 , a push-pull oil cylinder 32 located inside the jaw test bench 30 and used to push the active jaw 31 to move horizontally, and three clamping oil cylinders 33 respectiv...

Embodiment 2

[0037] Refer to attached figure 1 And attached Figure 9 . The implementation of this embodiment is basically the same as that of Embodiment 1, the difference is that the medium supply pressure device is an oil supply pressure device 4', which includes an oil pump 40' and a sealed oil storage tank 41 communicated with the oil pump 40' ', the sealed oil storage tank 41' is provided with two-way oil outlet pipes 410', 411', and the two-way oil outlet pipes 410', 411' correspond to the top pressure test bench 2 and the jaw type test bench 3 respectively. The medium outlet ports are connected, and each oil outlet pipe is equipped with a pressure reducing valve 42' for adjusting the oil pressure.

[0038]This testing machine is suitable for testing valves used on oil pipelines. It supplies constant oil pressure to the inside of the valve through the oil pressure device 4' to detect its oil pressure resistance, and observes the oil pressure gauge on the console 1 to display its in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com