Construction method of thermoplastic composite die of short tie track bed

A composite material and thermoplastic technology, which is applied in the field of rail transit engineering, can solve the problems of polluting the color of the concrete surface of the track bed, the heavy weight of the steel formwork, and affecting the line shape of the track bed, and achieve the effect of saving manpower and materials, saving formwork costs, and low cost input

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

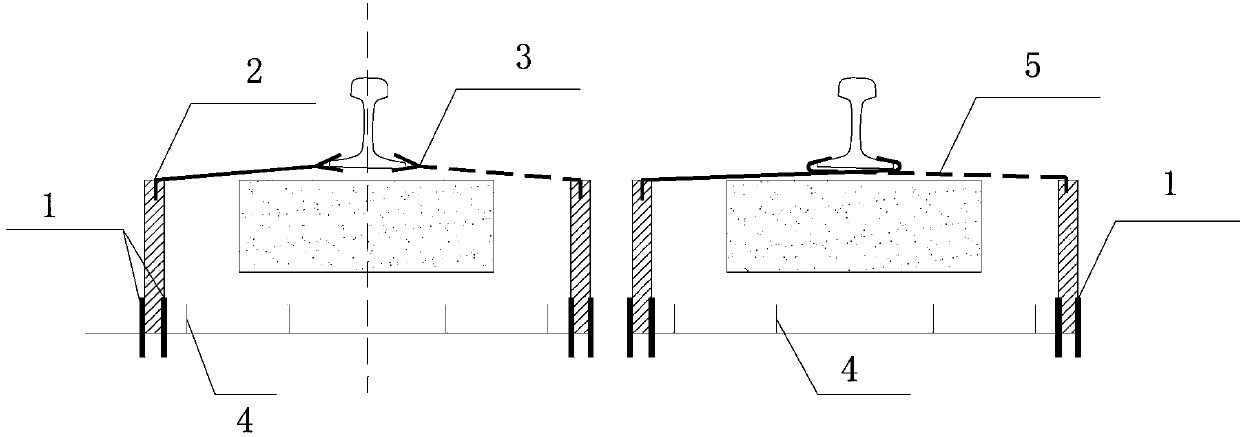

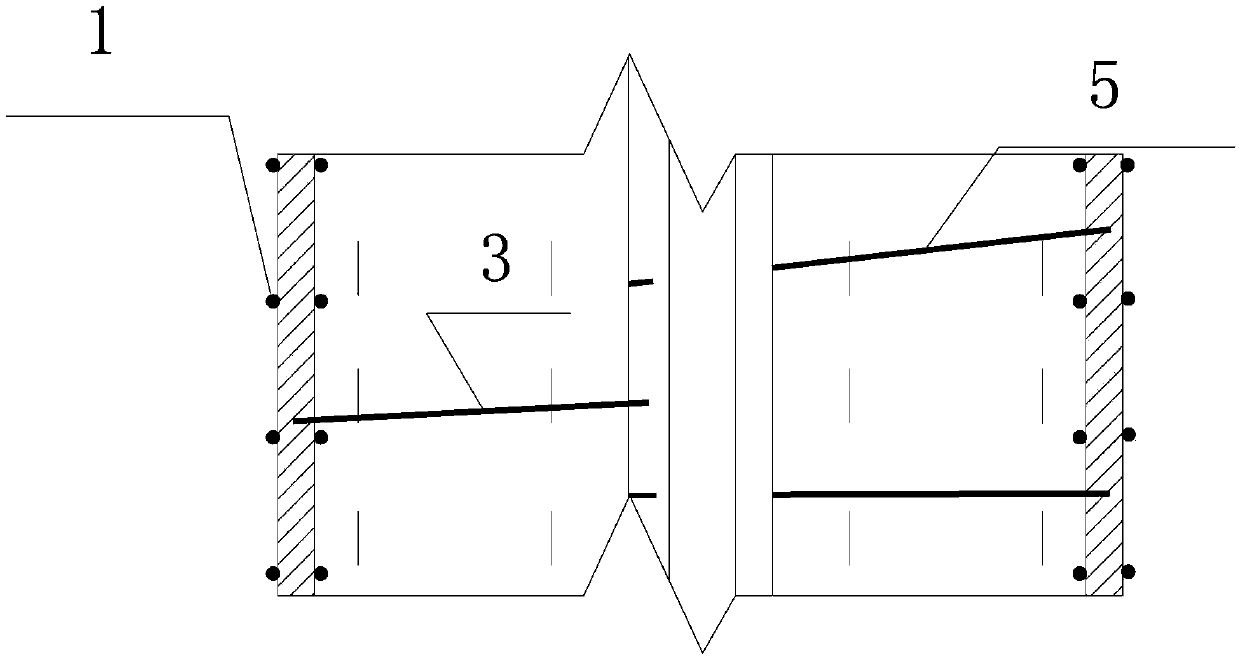

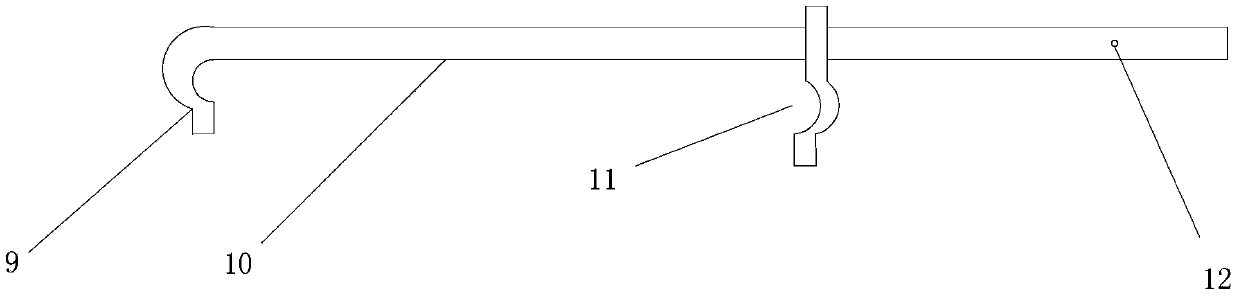

[0034] Below, the present invention will be further described in conjunction with accompanying drawing, and the steps and principle of this method are very clear to those skilled in the art. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

[0035] In the present invention, after the thermoplastic composite template is positioned by steel bars, square logs, etc., the template is fixed by step-by-step tightening, and then the concrete of the track bed is poured.

[0036] 1. Selection of thermoplastic composite formwork: the new thermoplastic composite formwork generally has a height between the top surface of the rail of the short sleeper track bed and the structural surface between 480 and 540mm, and the height of the track bed is less than 300mm. In this embodiment, a composite material with a width of 150mm and a length of 1500mm is selected. Two pieces of formwork are com...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com