Production method of fructose diphosphate sodium sterile powder

A kind of technology of sodium fructose diphosphate and production method, which is applied in the direction of preparation of sugar derivatives, sugar derivatives, sugar derivatives, etc., can solve the problems of lack of sterility, product quality decline, high equipment cost, etc., and achieve the goal of reducing contact Opportunity, aseptic quality assurance, and the effect of reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

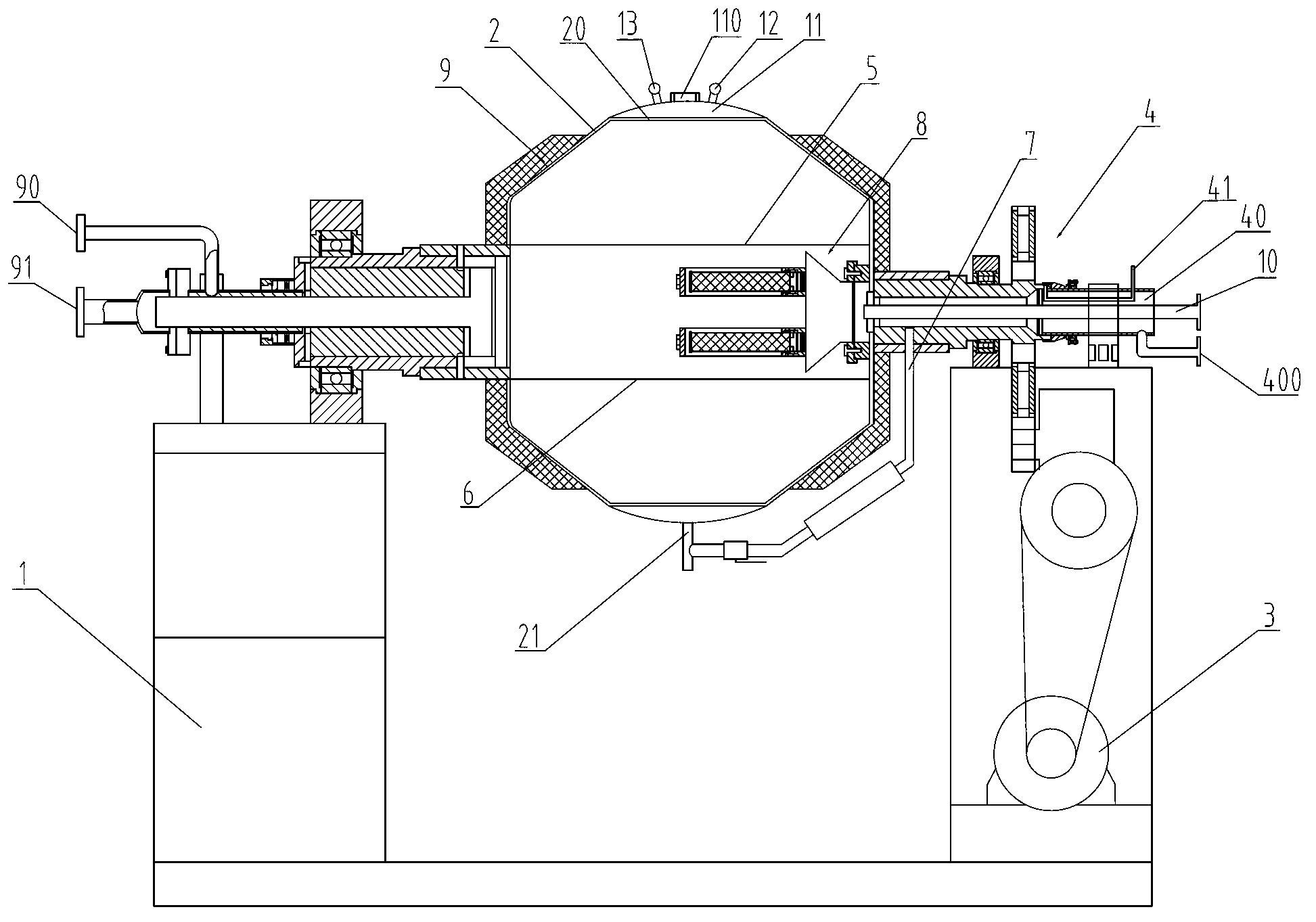

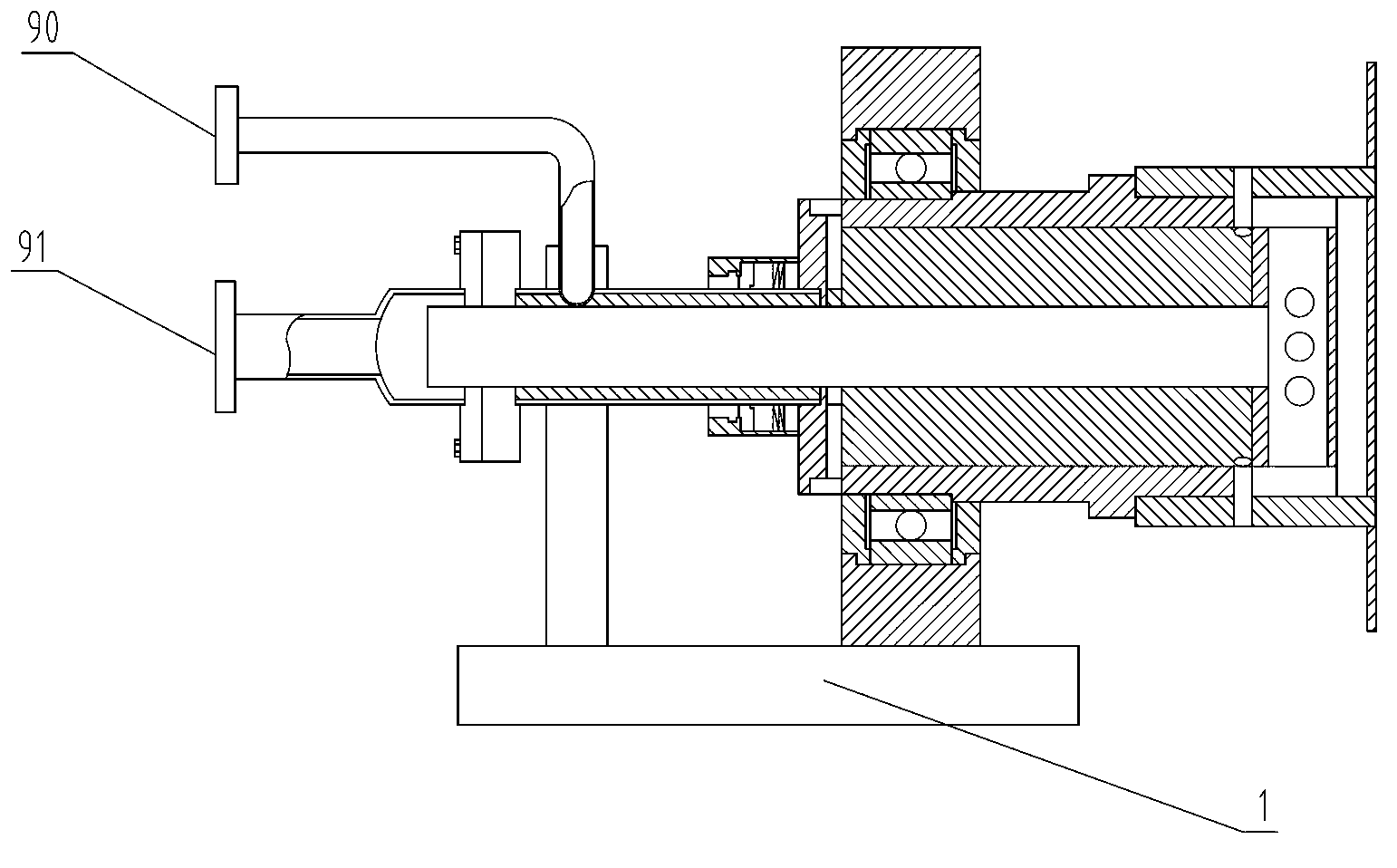

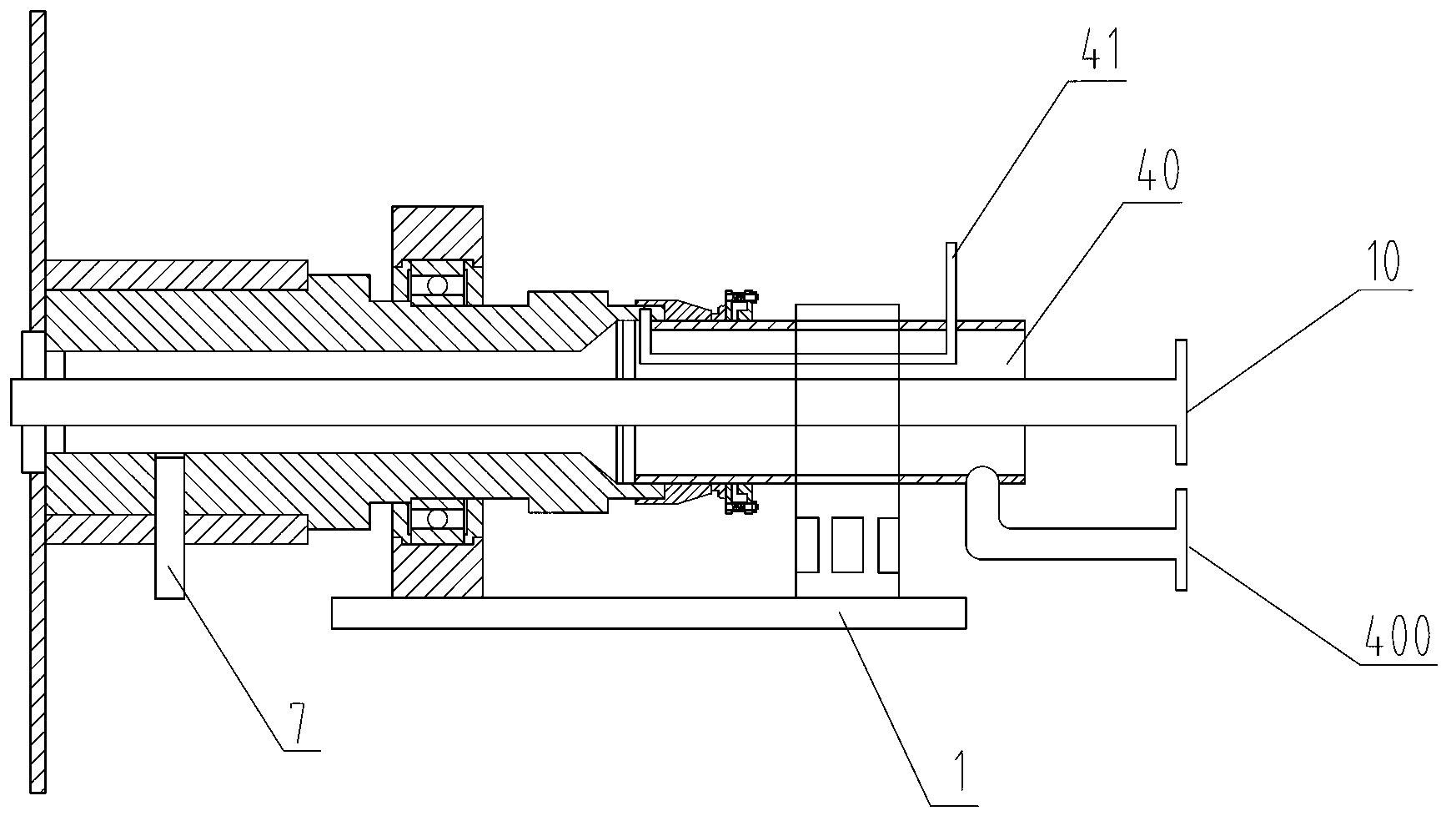

[0031] This embodiment provides a vacuum rotary dryer used in the method of the present invention. Such as Figure 1 to Figure 4 As shown, the vacuum rotary dryer includes a frame 1; a tank body 2 with an inlet and an outlet 20, the tank body 2 can be rotatably arranged on the frame 1, and its axis of rotation is consistent with the horizontal direction; A variable frequency motor 3 used to drive the tank body 2 to rotate; a vacuum device 4 connected to the tank body 2; a drying device for drying materials in the tank body 2; wherein the vacuum device 4 includes a vacuum tube that extends into the tank body 2 at one end 40. Vacuum pump; a filter screen 5 arranged in the tank body 2 for solid-liquid separation, a filtrate container 6 located below the filter screen 5, a filtrate discharge pipe 7 communicating with the filtrate container 6 for discharging the filtrate therein, A vacuum filter 8 arranged at the filtrate outlet of the filtrate container 6 .

[0032] In the dryin...

Embodiment 2

[0035] This embodiment provides a sterilizing filter device used in the method of the present invention. Such as Figure 5 with Image 6 As shown, the sterilizing and filtering device includes a fixed seat 15, two feed pipes 16 respectively arranged on the upper parts of both sides of the fixed seat 15, two discharge pipes 17 respectively arranged on the lower parts of the fixed seats 15 both sides, and two outlet pipes 17 arranged on each side. Five sets of ultrafiltration membrane modules 18 between the feed pipe 16 and the discharge pipe 17. There is a one-to-one correspondence between the five sets of ultrafiltration membrane modules 18 on both sides, and the upper and lower parts of the corresponding two ultrafiltration membrane modules 18 are communicated by connecting pipes 19 . The upper and lower ends of the central pipe 180 of the ultrafiltration membrane module 18 communicate with the feed pipe 16 and the discharge pipe 17 respectively. The structure of the ultra...

Embodiment 3

[0037] The present embodiment provides a kind of production method of sodium fructose diphosphate aseptic powder, specifically as follows:

[0038] Put 350kg of fructose diphosphate sodium bacteria powder raw material into a 1000L dissolving tank, add 300L of water for injection, heat the jacket, control the jacket temperature to 45°C, and filter it with a carbon rod after it is completely dissolved, and pass the filtrate through a 0.22 micron filter in turn After sterilizing and filtering with the sterilizing and filtering device described in embodiment 2, enter the intermediate storage tank, afterward, with the aseptic compressed air through sterilizing, the filtrate is pressed into the crystallization tank, and sterile alcohol (volume ratio 92% ) 780L. By adjusting the temperature of the water in the jacket of the crystallization tank, the temperature of the feed liquid is controlled at 28-30°C. After the temperature is stable, add 300g of qualified sodium fructose diphospha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com