A kind of method that sodium aminopropionate is converted into aminopropionic acid

A technology of sodium allanylpropionate and aminopropionic acid, which is applied in the field of ion exchange, can solve the problems of long process, long production cycle, and low total yield, and achieve the advantages of small floor area, reduced pipeline shrinkage, and low valve switching frequency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

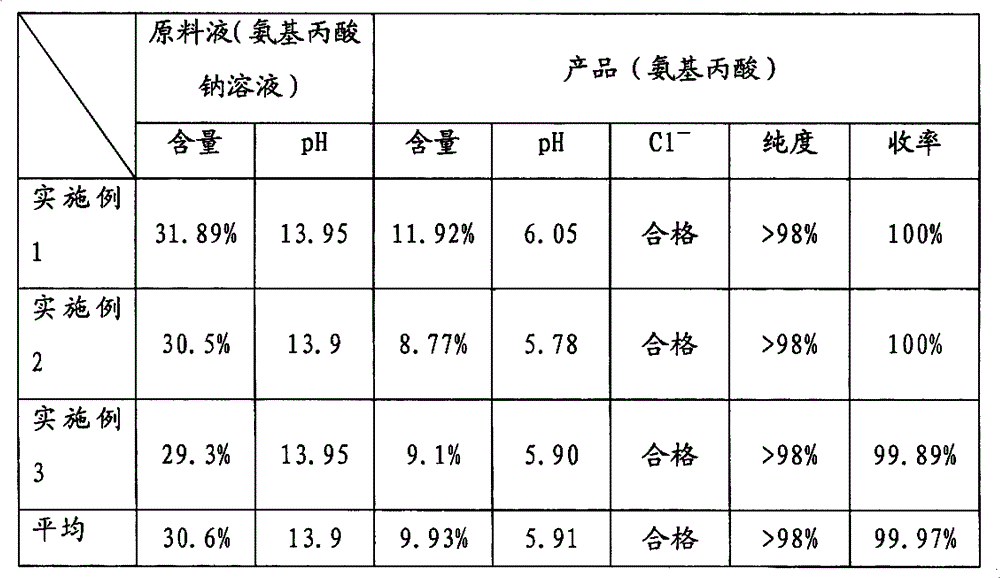

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

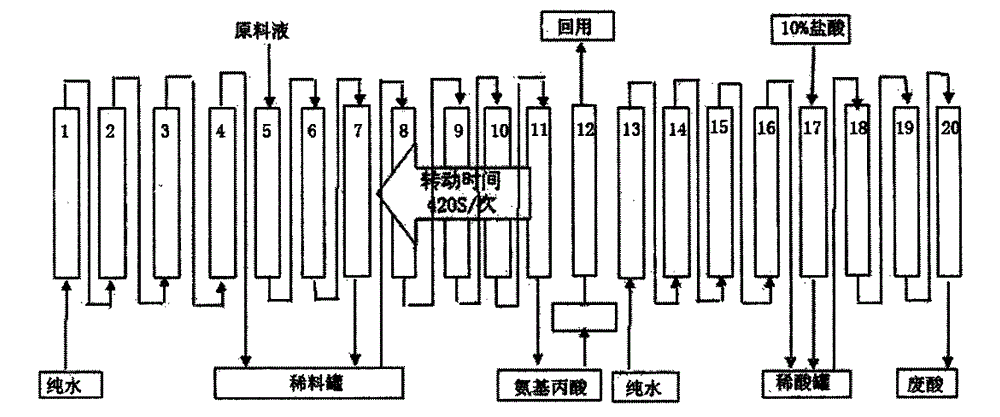

[0024] Such as figure 1 As shown, the method for converting sodium allanate into aminopropionic acid adopts a continuous ion exchange system with 20 separation units built in the system, and each separation unit is filled with a macroporous strong acid resin; the continuous ion exchange system is divided into five Regions, each of which consists of the following:

[0025] Transformation zone (5#-11#): Contains 7 separation units, divided into two sections, the front section contains 5#-7# separation units, the feed is raw material liquid, the rear section contains 8#-11# separation units, It is the mixed liquid of the intermediate tank; after the raw material liquid enters the 5#-7# separation unit in series in forward direction, its effluent and the effluent liquid in the conversion washing area are mixed into the intermediate tank, and the m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com