Method for solving problem of high-frequency driving acoustic resonance of high voltage sodium lamp

A high-pressure sodium lamp and acoustic resonance technology, applied in the field of lighting, can solve the problems of lamp extinguishing and blasting, arc bending, acoustic resonance, etc., and achieve the effects of saving electric energy, prolonging service life and improving light efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

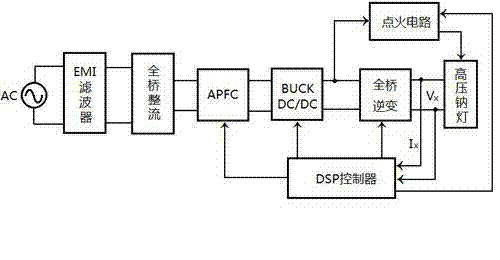

[0020] The present invention needs to be used in an electronic ballast adopting embedded control, and its core components are preferably DSP or single-chip microcomputer with timer, AD converter, PWM output controller and the like. The electronic ballast has conventional rectification, PFC (power factor correction), constant current or constant power control of the load (high pressure sodium lamp), DC / AC frequency conversion control. The present invention is added therein as a link of frequency conversion control.

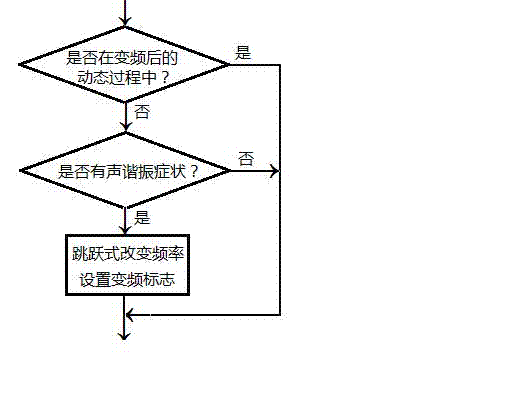

[0021] The realization method of the present invention is to continuously detect the acoustic resonance phenomenon during normal operation, once the initial symptom of the acoustic resonance is detected, it immediately jumps to work at another frequency. The specific method is that the embedded controller continuously rea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com