Method for preparing lifexm1-xpo4/c lithium ion composite cathode material

A technology of positive electrode materials and synthesis methods, applied in battery electrodes, electrical components, electrochemical generators, etc., can solve the problems of long mixing time of precursors, unevenness, poor performance of battery materials, etc., and achieve a controllable stoichiometric ratio, Controllable stoichiometry and low overall cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

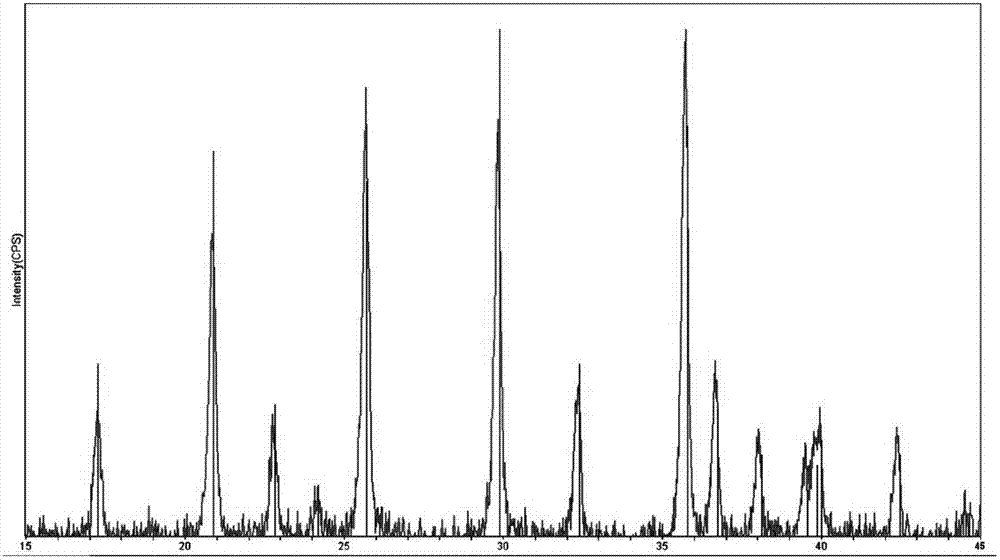

[0043] Example 1 LiFe 0.5 mn 0.5 PO 4 Synthesis of / C Composite Cathode Active Materials

[0044] In a specific embodiment of the present invention, LiFe 0.5 mn 0.5 PO 4 / C can be crafted by:

[0045] Step 1. Generate Fe 0.5 mn 0.5 PO 4 Precursor.

[0046] A co-precipitation reactor with a 5 L jacketed reactor vessel equipped with pH and temperature controllers was used in this experiment and a digital peristaltic pump was used to add the reagents, and the addition of sodium carbonate was automatically controlled by the pH controller. Reaction The contents of the reactor were stirred using an overhead stirrer at a rate of 2000 rpm. Reagents used in this study included iron(II) sulfate (1.0M), manganese sulfate (1.0M), phosphoric acid (1.0M) and sodium carbonate (1.0M). All solutions were prepared using deionized (DI) water degassed by boiling for 10 minutes. 1.0M FeSO prepared in degassed water 4 (0.5L) and 1.0MMnSO 4 (0.5 L) was added to the reactor and stirred ...

Embodiment 2

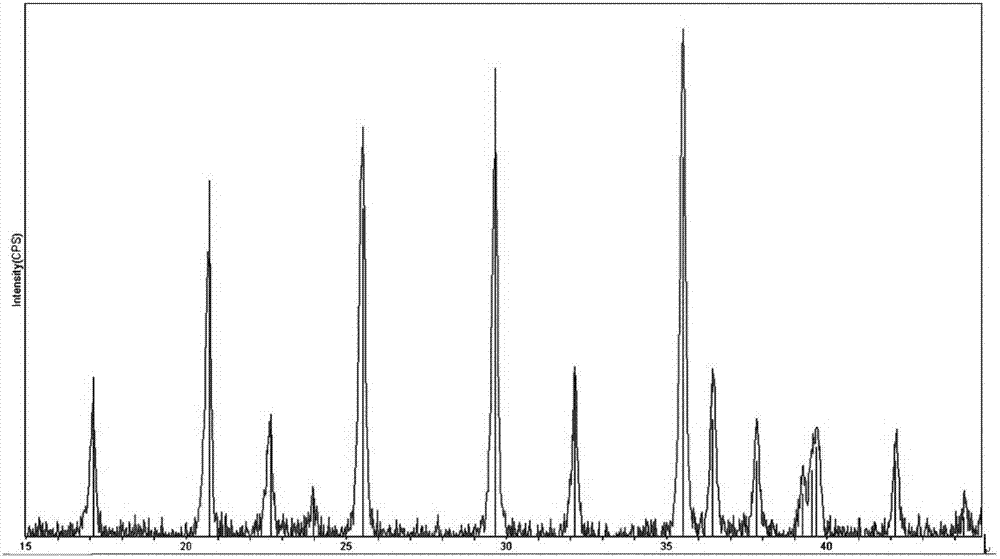

[0051] Example 2 LiFe 0.25 mn 0.75 PO 4 Synthesis of / C Composite Cathode Active Materials

[0052] In a specific embodiment of the present invention, LiFe 0.25 mn 0.75 PO 4 / C can be synthesized in the following ways. Step 1. Generate Fe 0.25 mn 0.75 PO 4 Precursor.

[0053] A co-precipitation reactor with a 5 L jacketed reactor vessel equipped with pH and temperature controllers was used in this experiment and a digital peristaltic pump was used to add the reagents, and the addition of sodium carbonate was automatically controlled by the pH controller. Reaction The contents of the reactor were stirred using an overhead stirrer at a rate of 2000 rpm. Reagents used in this study included iron(II) sulfate (1.0M), manganese sulfate (1.0M), phosphoric acid (1.0M) and sodium carbonate (1.0M). All solutions were prepared using deionized (DI) water degassed by boiling for 10 minutes. 1.0M FeSO prepared in degassed water 4 (0.25L) and 1.0MMnSO 4 (0.75L) was added to the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com