Centrifugal needle-free electrostatic spinning device

An electrospinning, needle-free technology, applied in textiles and papermaking, filament/thread forming, feeding solution to the spinneret, etc., to improve product quality, reduce power consumption, and reduce production costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Polyvinyl alcohol (PVA) aqueous solution was used for electrospinning. The degree of polymerization of PVA was 1700, the degree of alcoholysis was 99mol%, and the molecular weight was 74800. The spinning solution was prepared by dissolving PVA powder in deionized water for 2 hours at 80°C and standing for 2 hours.

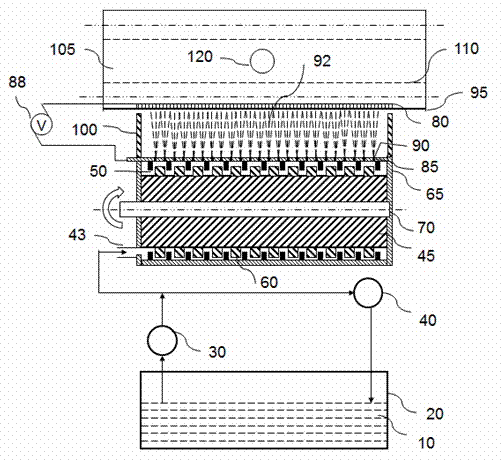

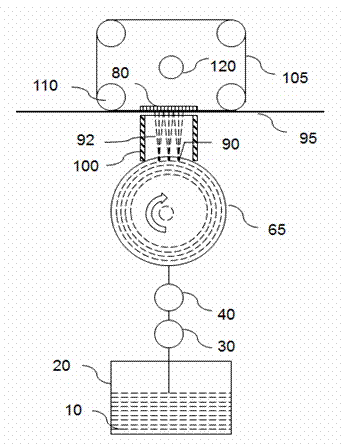

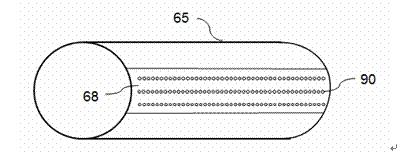

[0034] The receiving electrode 80 is a permeable thin-walled porous aluminum plate, and the base fabric 95 is a melt-blown non-woven fabric. Electrospinning setup (see figure 1 , 2 and 3) the diameter of the inner roller 45 of the spinning system is 200mm, and the rotating speed is 500rev / min; the diameter of the outer cylinder 65 is 300mm, and the synchronous linear motion speed of the inner roller 45 and the outer cylinder 65 along the width direction is 25m / min. min. Outer and inner convex nails 60 and 50 on the inner round roller 45 and outer cylinder 65 are rectangular cross-sections, and its height is 40mm, wherein the height of the outer convex nai...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Wall thickness | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com