Yellow water circulation and fermentation method and yellow water circulation device

A fermentation method and water circulation technology, applied in the preparation of alcoholic beverages, can solve the problems of limiting the output of high-quality liquor, without manual intervention in the flow of yellow water in the cellar, shortening the production cycle, improving the uncontrollable fermentation, and improving the quality of liquor. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

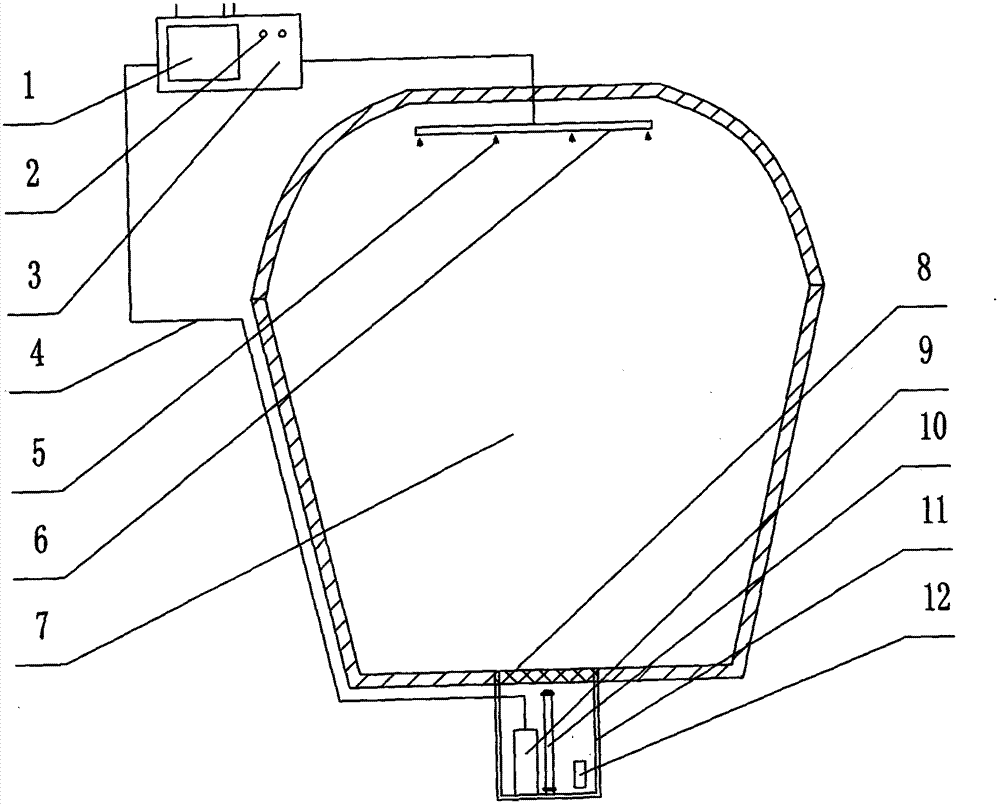

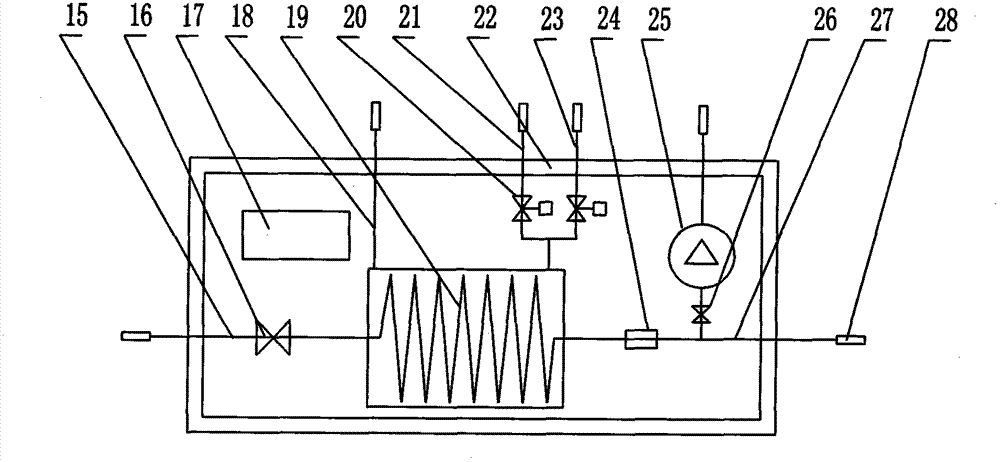

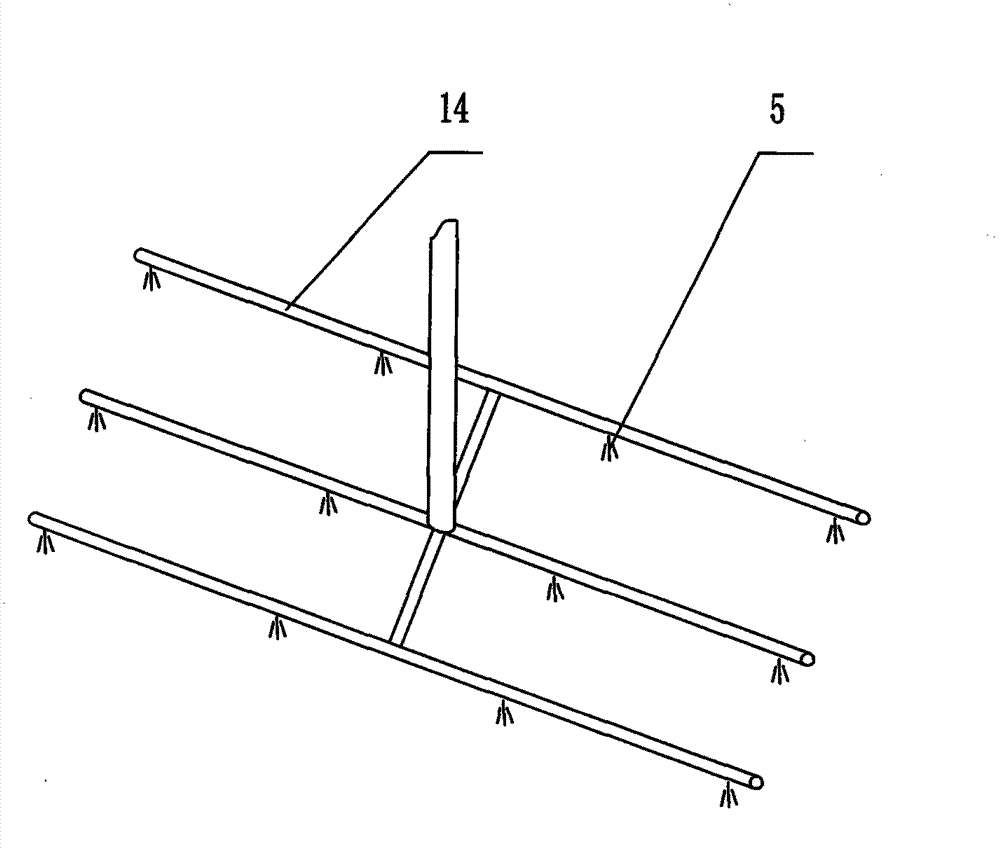

[0018] Three old cellars with better and similar wine production quality were selected. The conventional fermentation time was 70 days. Two of the cellars 7 were equipped with yellow water circulation devices, and one cellar 7 was fermented by the traditional process to compare the fermentation conditions of the two processes. After 50 days of fermentation, the fermentation of one experimental cellar 7 was terminated, and the relevant physical and chemical indicators were tested, and the fermentation of the other experimental cellar 7 and the traditional process cellar 7 was terminated after 70 days of fermentation, and the relevant physical and chemical indicators were tested. The index values are listed in Table 1. The specific operation is as follows: before fermentation, according to the production practice experience, input the fermented grain fermentation temperature curve into PLC 17, and start the timing function. The yellow water enters the yellow water collection ta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com