Adsorption separation device and method for improving base oil viscosity index

A technology of adsorption separation and viscosity index, which is applied in the multi-stage series refining process, etc., can solve the problem of difficult base oil viscosity index, and achieve the effect of improving viscosity index and oxidation stability, convenient use and small investment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

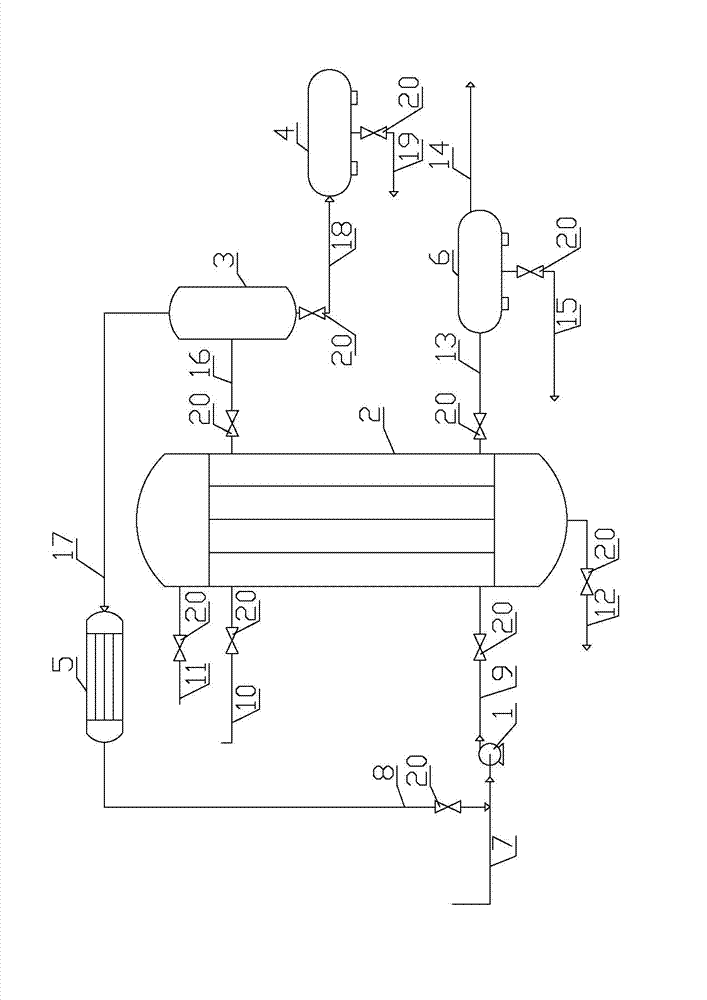

[0018] Embodiment 1, this adsorption separation device that improves base oil viscosity index comprises pump 1, adsorption tower 2, fractionation tank 3, buffer tank 4, condenser 5 and recovery tank 6; Adsorption tower 2, fractionation tank 3, buffer tank 4, The condenser 5 and the recovery tank 6 are respectively fixedly installed on the bracket, and the inlet end of the pump 1 is fixedly connected with a first pipeline 7, and the outlet of the condenser 5 is fixedly connected together through the second pipeline 8 and the first pipeline 7, and the pump 1 The outlet of the outlet is fixedly connected together with the lower shell-side inlet of the adsorption tower 2 through the third pipeline 9, and the fourth pipeline 10 and the fifth pipeline 11 are fixedly connected on the top of the adsorption tower 2, and the shell of the fourth pipeline 10 and the adsorption tower 2 The pipe-side inlet of the fifth pipeline 11 is fixedly connected with the pipe-side inlet of the adsorpti...

Embodiment 2

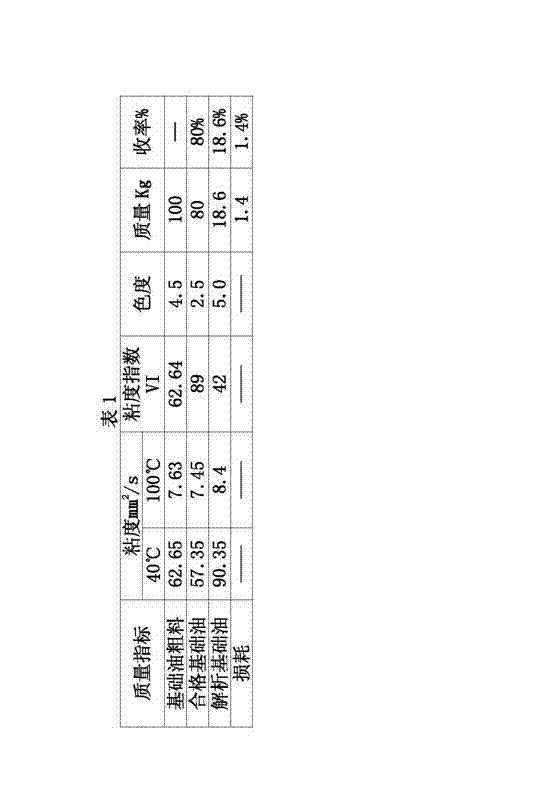

[0021] Embodiment 2, the adsorption separation method that uses the adsorption separation device that improves base oil viscosity index is carried out according to the following steps: the first step, at first the diluent in the second pipeline 8 is added in the first pipeline 7, with the first The crude base oil in line 7 is mixed to reduce its viscosity to 2.0 mm at 40°C 2 / s to 3.5mm 2 / s; In the second step, the steam in the fifth pipeline 11 is passed into the tube in the adsorption tower 2, and the mixed diluent and base oil crude material are delivered to the adsorption tower through the pump 1 and the third pipeline 9 In the shell side of the adsorption tower 2, after being adsorbed by the adsorbent in the shell side of the adsorption tower 2 and exchanging heat with the steam in the tube side of the adsorption tower 2, the temperature reaches 90°C to 130°C to become a vapor-liquid mixed phase; the third step, the vapor The liquid mixed phase enters the fractionating ...

Embodiment 3

[0022] Embodiment 3, the adsorption separation method that uses the adsorption separation device that improves base oil viscosity index is carried out according to the following steps: the first step, at first the diluent in the second pipeline 8 is added in the first pipeline 7, with the first The crude base oil in line 7 is mixed to reduce its viscosity to 2.0 mm at 40°C 2 / s or 3.5mm 2 / s; In the second step, the steam in the fifth pipeline 11 is passed into the tube in the adsorption tower 2, and the mixed diluent and base oil crude material are delivered to the adsorption tower through the pump 1 and the third pipeline 9 In the shell side of the adsorption tower 2, after being adsorbed by the adsorbent in the shell side of the adsorption tower 2 and exchanging heat with the steam in the tube side of the adsorption tower 2, the temperature reaches 90°C or 130°C to become a vapor-liquid mixed phase; in the third step, the vapor The liquid mixed phase enters the fractionati...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com