Preparation method of red-green-blue blended white light phosphor

A phosphor, red, green and blue technology, applied in the field of luminescent material preparation and application, can solve the problems of fluorescence quenching, poor dispersion, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

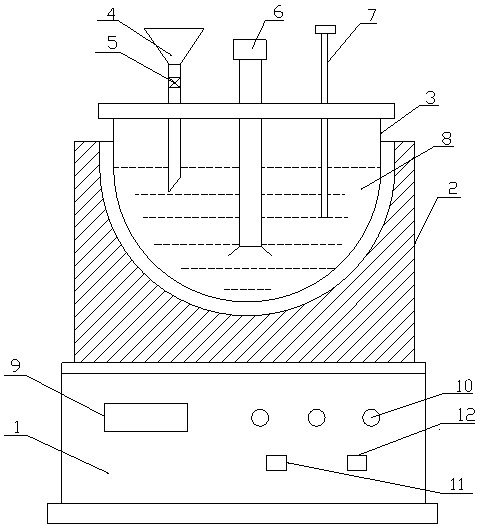

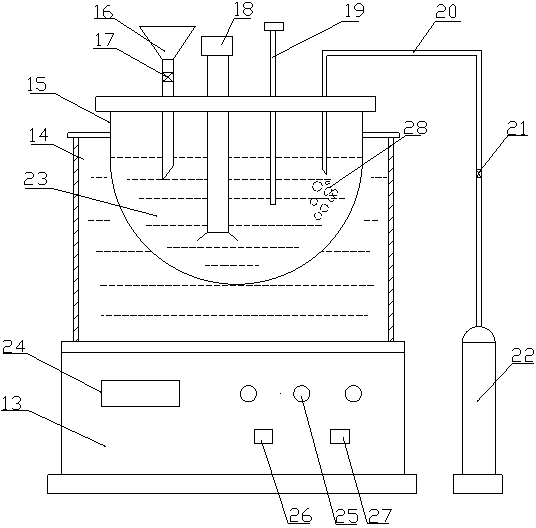

[0149] The present invention will be further explained below in conjunction with the drawings:

[0150] figure 1 As shown, in order to prepare the red, green, and blue rare earth complexes, the position of each part must be correct, proportioning according to the quantity, and operation in order.

[0151] The amount of chemical substances used in preparation is determined according to the preset range, in grams, milliliters, centimeters 3 It is the unit of measurement.

[0152] The preparation of red, green, and blue rare earth complexes is carried out in a three-necked flask, and is completed in the process of heating, stirring and adjusting the pH;

[0153] The upper part of the first electric controller 1 is an electric heating mantle 2. A three-necked flask 3 is placed on the electric heating mantle 2, and a first dropping funnel 4, a first control net 5, and a first stirring are arranged on the three-necked flask 3 from left to right. Device 6, the first pH meter 7; on the front ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com