Industrial sewage deep denitrifying and recycling process

A technology for deep denitrification and industrial sewage, applied in the field of environmental protection sewage treatment, can solve the problems of in-depth denitrification treatment of difficult industrial sewage, incomplete denitrification, high total nitrogen in effluent, saving power consumption, good economic and social benefits , The effect of preventing sludge loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

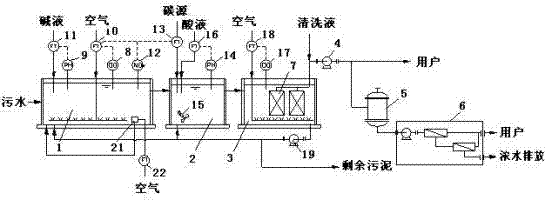

[0016] see figure 1 , The invention discloses a deep denitrification and reuse process of industrial sewage. As shown in the figure: it is processed in a system consisting of the first-stage aerobic pool 1, the anoxic pool 2, the second-stage aerobic pool 3 and the produced water pump 4. The specific process is: the sewage first enters the first-stage aerobic pool 1, the nitrification mixture of the first-stage aerobic pool 1 enters the anoxic pool 2, the mixed liquid of the anoxic pool 2 enters the second-stage aerobic pool 3, and the effluent of the system The produced water is pumped out from the membrane module by the pump 4 and sent to the user. Wherein: the first-stage aerobic pool 1 is provided with the air pipeline of the first air flow controller 10, the alkali adding pipeline of the first lye flow controller 11, the first DO measuring instrument 8 and the first pH meter 9. The first DO measuring instrument 8 automatically controls the first air flow controller 10, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com