Self-assembly preparation method of colloid microsphere single-layer film

A technology of colloidal microspheres and single-layer films, which is applied in nanostructure manufacturing, nanotechnology, nanotechnology, etc., can solve the problems of difficult to form close-packed structures, low film-forming quality, and small film-forming area. High film quality, simple and controllable operation, and shortened time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

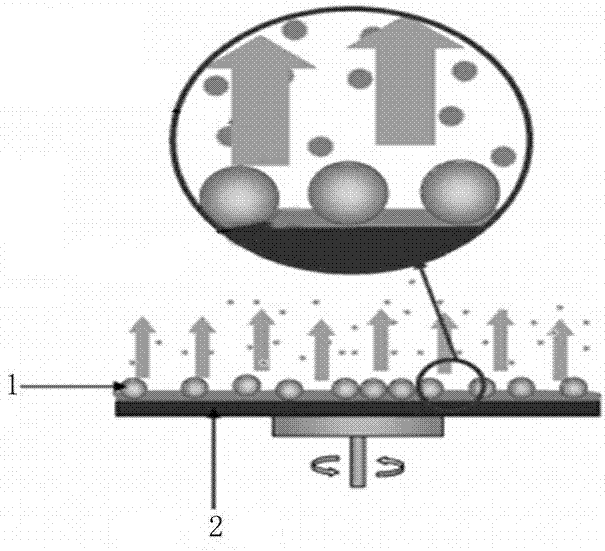

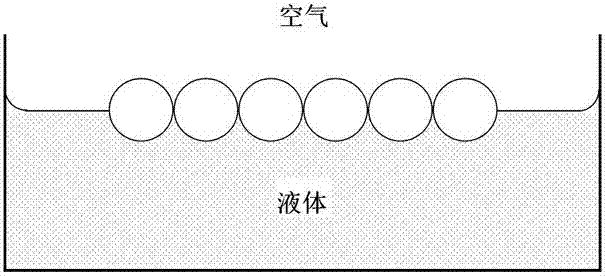

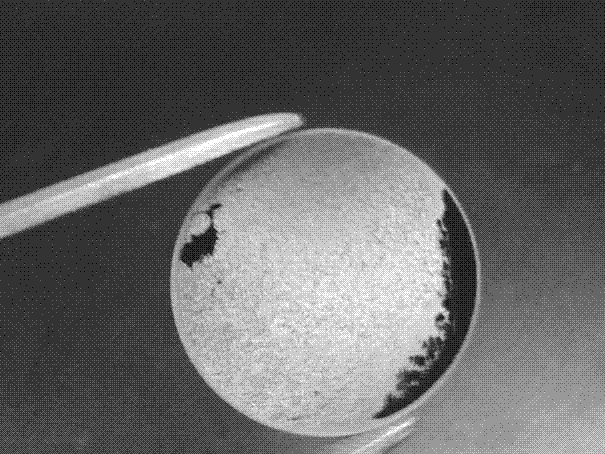

[0026] A self-assembly preparation method of a colloidal microsphere monolayer film. After the colloidal microsphere monolayer film with a large area and high coverage is obtained by using the spin coating method, the colloidal microsphere is extruded by the surface tension of the liquid by the vapor-liquid interface method Close-packed array of hexagons. First, draw 40 μL of the colloidal microsphere mixed solution with a quantitative dropper, drop it on the surface of the substrate, and spin-coat the colloidal microsphere mixed solution on the substrate, first at low speed and then at high speed, and the relatively tightly arranged colloidal microspheres are obtained on the substrate. Spherical monolayer film, the low speed speed is 900rpm / min, the high speed speed is 1500rpm / min, and the time is 6s and 30s respectively; secondly, the substra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com