Double-horizontal-spindle concrete mixing and conveying apparatus

A conveying device and concrete technology, which is applied in the direction of cement mixing device, clay preparation device, mixing operation control device, etc., can solve the problems of unsatisfactory mixing effect, uneven dry and wet concrete, inability to flexibly adapt to narrow space, etc., and reduce the number of workers Labor intensity, good stirring effect, and the effect of reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

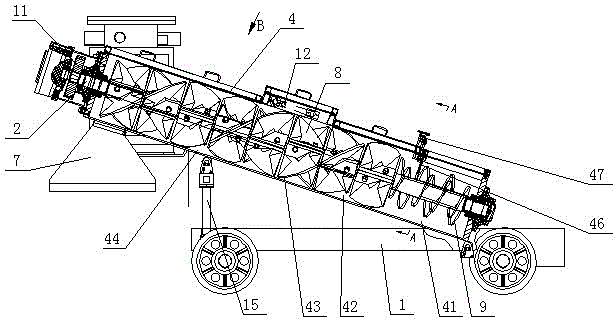

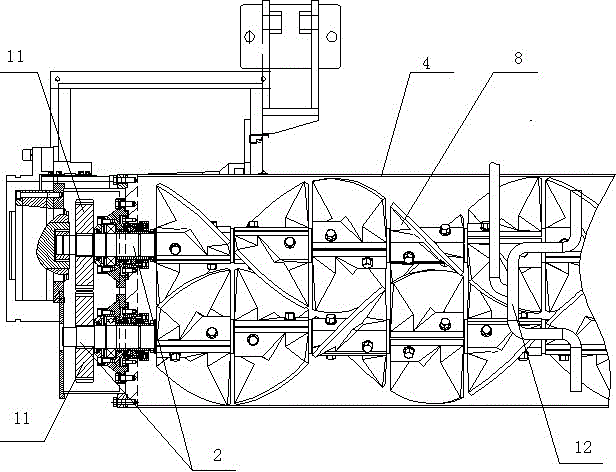

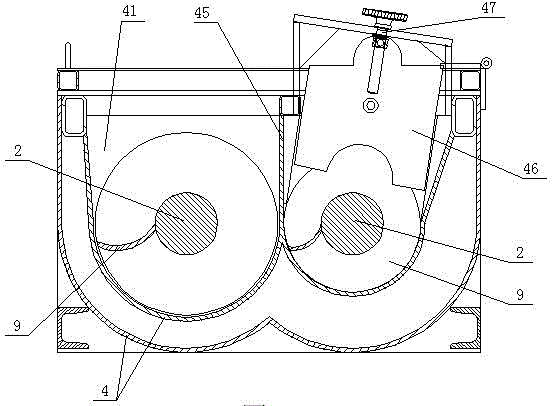

[0022] Such as figure 1 and figure 2 The shown twin-shaft concrete mixing and conveying device, for the convenience of description, takes the feeding part as the rear part of the device, which includes an underframe 1, and the underframe 1 is equipped with a mixing barrel 4 that is inclined from the rear forward and upward. , the rear portion of the mixing drum 4 is hinged on the underframe 1, and the front portion of the underframe 1 is equipped with a retractable push rod 15 that leans against the bottom of the mixing drum 4. Push rod 15 can be hydraulic oil cylinder, also can adopt mechanical mode, and the present invention has adopted following structure: as Figure 5 , Figure 6 and Figure 7 As shown in , the ejector rod 15 includes a lower hinge seat 151 whose lower end is hinged on the chassis 1 and an upper hinge seat 152 whose upper end is hinged with the mixing barrel 4. The upper hinge seat 152 is equipped with a hinge shaft, and the front part of the mixing ba...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com