Clamping tool for punching equipment pipe shell

A technology for clamping tools and stamping equipment, which is applied in the field of clamping tools, can solve problems such as poor quality of stamping equipment shells, processing reference errors, and equipment position errors, and achieve high work efficiency, small position tolerances, and small tolerances.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

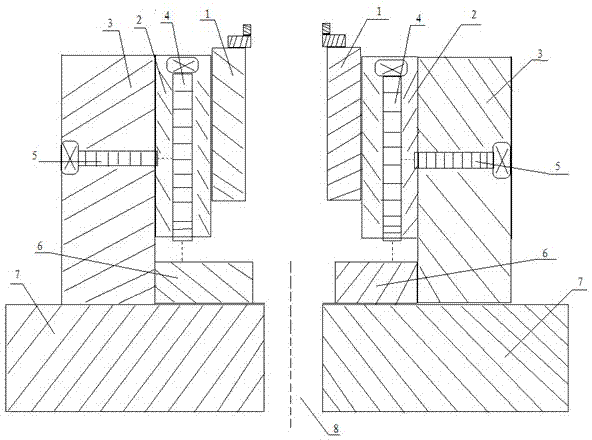

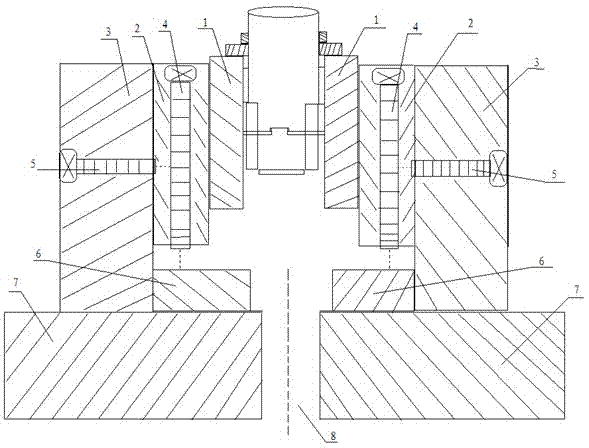

[0018] Such as figure 1 and figure 2 As shown, the clamping tool of the pipe shell of stamping equipment according to the present invention comprises a hollow cylindrical split sleeve (1), an inner ring (2) positioned at the outer periphery of the split sleeve (1), and an outer ring positioned at the outer periphery of the inner ring (2). The outer ring (3) is provided with 4 axial adjustment screws (4) on the inner ring (2), and 4 radial adjustment screws (5) are provided on the outer ring (3), and the inner ring (2) A washer (6) is provided below the washer (6), and a clamp (7) is provided below the washer (6), and a circular hole (8) is provided at the center of the washer (6) and the clamp (7). And the diameter of the circular hole (8) is smaller than the diameter of the open sleeve (1).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com