Porous part boring method and equipment thereof

A technology for parts and boring, applied in drilling/drilling equipment, turning equipment, boring/drilling and other directions, can solve the problem of increasing boring processing cost, small radial clearance of guide sleeve, unable to ensure processing accuracy, and inability to Repair and other problems to achieve the effect of improving production efficiency, preventing friction and heating, and improving machining accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

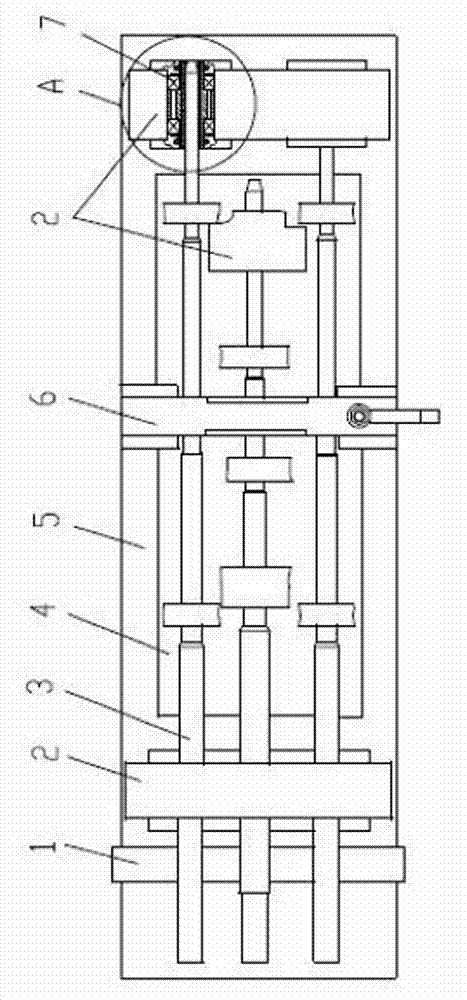

[0015] control figure 1 and figure 2 The operation and use steps of the present invention are further described: a method for boring a porous part, the method comprising: a step of boring a porous part 4 with a horizontal boring machine; The rod 3 is positioned, and the boring bar 2 drives the rotating guide sleeve 8 of the internal bearing 7 of the boring plate 2 to rotate during the cutting process, and at the same time moves horizontally in the rotating guide sleeve 8 .

[0016] The blank of the porous part 4 is fixed on the workbench 5, the boring bar 3 is moved out in the main shaft of the boring machine, one end of the boring bar 3 is connected with the main shaft clamp of the boring machine, and the two ends of the boring bar 3 are located inside the boring template 2 In the rotating guide sleeve 8 of the bearing 7, the bori...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com