Preparation method of probiotic fermented feed

A technology of fermented feed and probiotics, applied in the field of preparation of probiotic fermented feed, can solve the problems of low quality of raw materials directly used, no effective use, no solutions, etc., so as to shorten the breeding cycle, improve the taste, and improve the investment. small effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

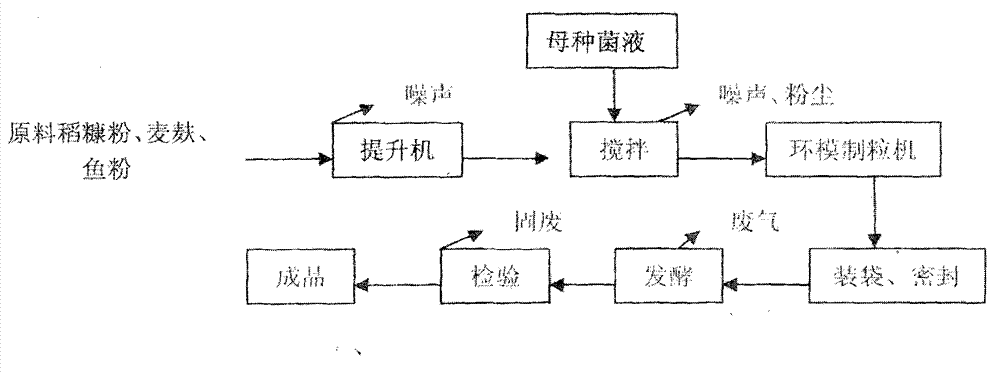

Image

Examples

Embodiment 1

[0020] 50 parts of rice bran powder, 15 parts of bran, 3 parts of fish meal, 30 parts of rice bran, 20 parts of cornmeal, 5 parts of soybean meal, 2 parts of soybean lecithin, 1 part of glutamic acid, 2 parts of methionine, 5 parts of Chinese herbal medicine extract.

[0021] Enter the mixer from the elevator, and then evenly add the mother seed bacteria liquid to the solid feed, so that the water content of the solid feed reaches 35%. Hold it in a state of being clenched by hand and dispersing when touched. After stirring, it enters the ring. The molding granulator squeezes and granulates (produces granular or powdered feed according to user needs), puts it into an inner bag, tightens the mouth of the bag and seals it. The environment temperature is controlled at 35℃ for 7 days and the fermentation is successful if there is an apple fragrance. Ship to the user after passing the inspection.

Embodiment 2

[0023] 70 parts of rice bran powder, 30 parts of bran, 10 parts of fish meal, 30 parts of rice bran, 20 parts of cornmeal, 5 parts of soybean meal, 2 parts of soybean lecithin, 1 part of glutamic acid, 2 parts of methionine, 5 parts of Chinese herbal medicine extract.

[0024] Enter the mixer from the elevator, and then evenly add the mother seed bacteria liquid to the solid feed, so that the water content of the solid feed reaches 45%. Hold it in the state of being clenched by hand and dispersing when touched. After stirring, it enters the ring. The molding granulator squeezes and granulates (produces granular or powdered feed according to user needs), puts it into an inner bag, tightens the mouth of the bag and seals it. The environment temperature is controlled at 25℃ for 7 days, and the fermentation is successful if there is an apple fragrance. Ship to the user after passing the inspection.

Embodiment 3

[0025] Embodiment 3 is the best embodiment, and its matching ratio is as follows:

[0026] 60 parts of rice bran powder, 20 parts of bran, 5 parts of fish meal, 30 parts of rice bran, 20 parts of cornmeal, 5 parts of soybean meal, 2 parts of soybean lecithin, 1 part of glutamic acid, 2 parts of methionine, 5 parts of Chinese herbal medicine extract.

[0027] The specific functions are as follows:

[0028] 1. The feed mixed with probiotics is 20%-30% more nutritious than the general full-price feed at the same price.

[0029] 2. The solid probiotics can decompose the macromolecular organic matter in the feed into small molecular organic matter after being mixed into the feed, which is conducive to the direct absorption of the animal intestines and greatly improves the utilization rate of the feed. In addition, the bacteria itself can secrete and synthesize a large number of active enzymes and other substances, which greatly improves the nutritional value of feed. It has been determine...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com