Warm white light-emitting diode (LED) and manufacturing method thereof

A technology for light-emitting diodes and a manufacturing method, which is applied to semiconductor devices, electrical components, circuits, etc., can solve the problems of large package structure, mixed light, and high cost, and achieve the effects of reducing the volume of the package structure, optimizing the process flow, and saving manufacturing costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

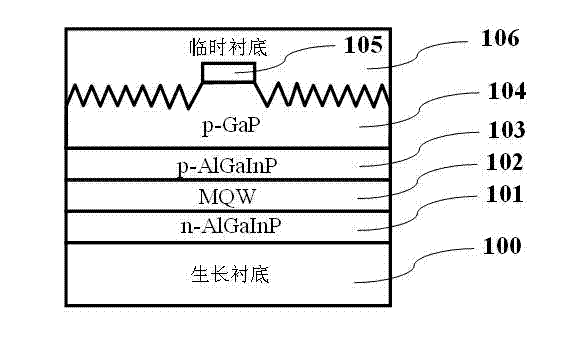

[0033] like Figure 8 and 9 As shown, a warm white LED includes a solder layer 300, which has two major surfaces; a red wafer mirror system located on the first major surface of the solder layer 300; a blue light coated with yellow YAG phosphor 400 The wafer mirror system is located on the second main surface of the bonding layer 300; the area of the lower surface of the red chip occupies one-third of the area of the upper surface of the blue chip.

[0034] The red light wafer mirror system includes a red light wafer and a first reflective layer, the first reflective layer is made of grid-like SiO 2 The dielectric layer 107 and the Ag metal reflective layer 108 are composed; the red light chip is composed of the n-AlGaInP layer 101, the light emitting layer 102, the p-AlGaInP layer 103, the roughened GaP window layer 104 and the N electrode 105 from bottom to top.

[0035] The blue light chip mirror system includes a blue light chip and a second reflective layer 204. The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com