Methods for detecting section shape and radial profile degree of cellulose acetate fibers

A technology of cross-sectional shape and acetate fiber, which is applied in the detection field of acetate fiber cross-sectional shape and radial irregularity, can solve the problems of low efficiency and data representation, and achieves the advantages of shortening test time, solving low efficiency and improving sample preparation speed. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

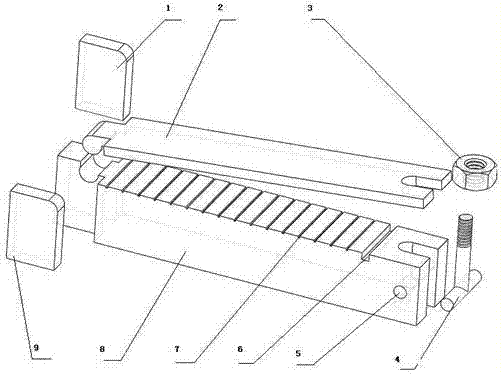

[0030] Such as figure 1 As shown, the sampler for tow prefabrication of the sample of the present invention is composed of: a sampler base 8, a strand pressing plate 2, a front positioning stopper 9 and a rear positioning stopper 1. There are several wires on the sampler base 8. The strand fixing groove 7 and the ribbon fixing groove 6, the sampler base 8 and the wire strand pressing plate 2 are connected by pressing bolts 4, and the front positioning stopper 9 and the rear positioning stopper 1 are respectively on both sides of the tail end of the sampler base 8. According to the single fiber linear density and the single fiber linear density, the rectangular cross-sectional area of the strand fixing groove in the sampler is set, and the number of strand fixing grooves is set according to the number of strands to be detected.

[0031] Set the size of the strand fixing groove 7 according to the cross-sectional area of the number of fibers. The shape of the groove is square or ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com