Tunneling, anchoring and supporting integrated machine

An all-in-one machine, anchoring and protecting technology, which is used in slitting machinery, bolt installation, mining equipment, etc., can solve problems such as inability to fold, damage to the tunneling device, and trembling of the anchoring device, and achieve convenient control, compact structure, and work. reliable results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The accompanying drawings disclose the specific structures of the embodiments of the present invention without limitation, and the present invention will be further described below in conjunction with the accompanying drawings.

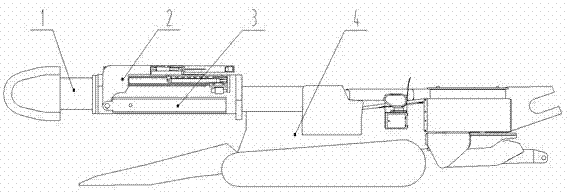

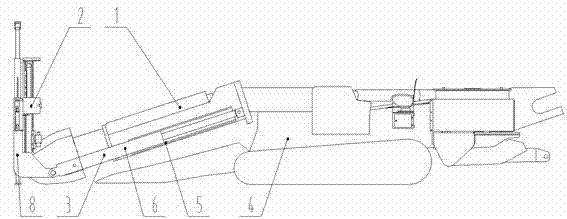

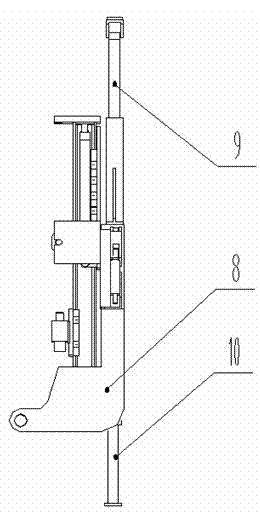

[0022] Depend on figure 1 , figure 2 It can be seen that the present invention includes a tunneling device 1, which is hinged on the body 4, an anchor protection device 2 is provided on the tunneling device 1, and a hydraulic guide device 3 is provided on both sides of the tunneling device 1, and one end of the hydraulic guide device 3 is fixedly connected. At the rear of the tunneling device 1 , the other end is hinged to the frame body 8 of the anchor protection device 2 . In the initial excavation state, the anchor protection device 2 is placed above the hydraulic guide device 3 after being folded along the hinged rotation.

[0023] In this embodiment, the hydraulic guiding device 3 includes a fixed guide 5 and a sliding guide 6 sliding o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com