Construction method of underground deep foundation concrete by reverse formworks

A construction method and concrete technology, which can be used in infrastructure engineering, excavation, construction, etc., can solve the problems of not being able to withstand lateral pressure, collapse, deformation, etc., and achieve the effect of reliable quality and prevention of quicksand and soil collapse.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

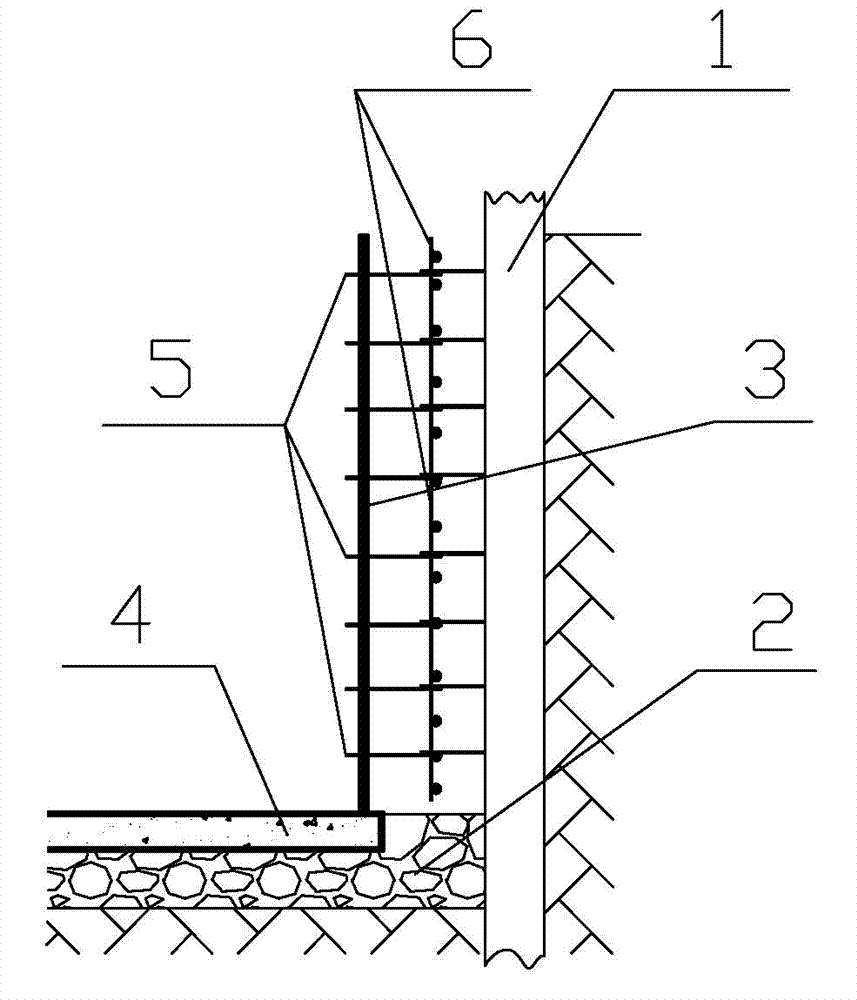

[0037] A kind of underground deep foundation concrete antiform construction method of the present invention is characterized in that comprising the following steps:

[0038] a. Construction support piles

[0039] The foundation is positioned and laid out according to the coordinate size of the drawing, and then concrete support piles are constructed near the periphery of the foundation so that the edge distance is 300-500mm. The concrete support piles are concrete pouring piles or concrete continuous retaining walls.

[0040] b. Excavation of the foundation pit support counter-model, which includes the following steps:

[0041] (1) Excavate the foundation pit when the supporting piles reach the health-preserving strength;

[0042] (2) Excavate to the level of the bottom of the foundation pit to lay a cushion;

[0043] (3) Accurately position and lay out the foundation on the cushion;

[0044] (4) Set up the anti-mold according to the setting-out support;

[0045] Among the...

Embodiment 2

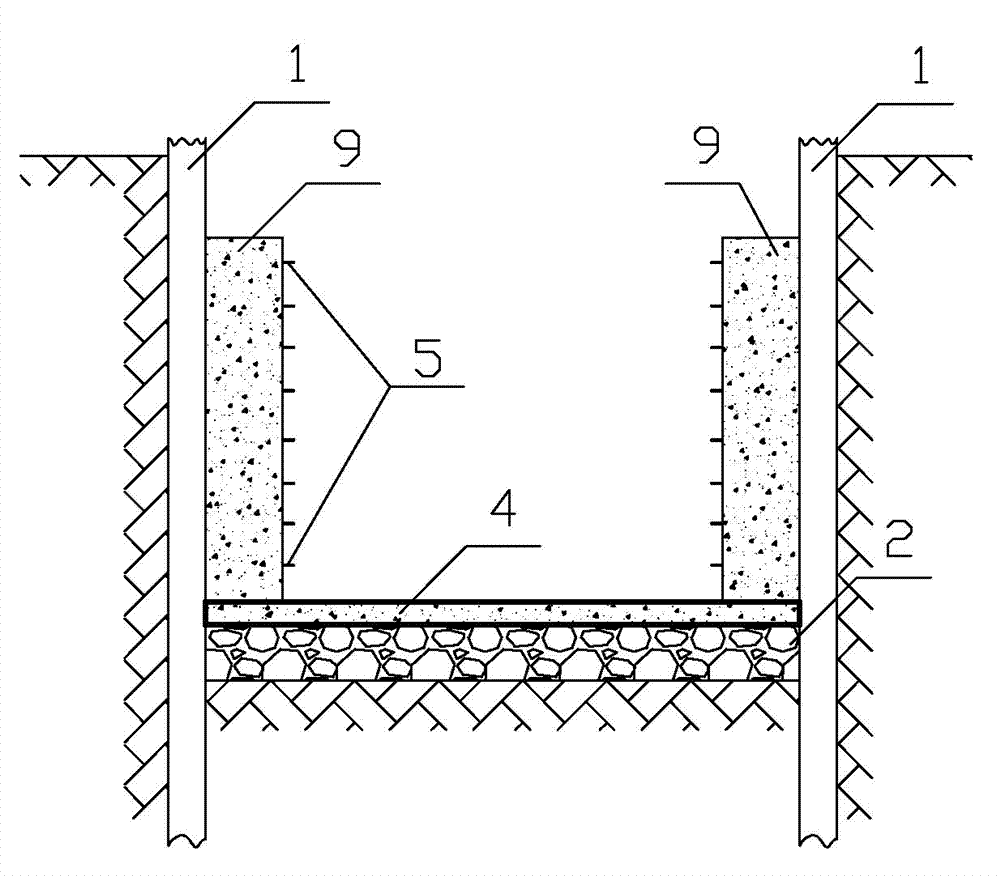

[0051] figure 2 It is a schematic diagram of another supporting mode of the counter-form in the embodiment of the present invention, except that the supporting mode of the counter-form uses scaffolding steel pipes to support the formwork: the support system is set up with wooden squares, scaffolding steel pipes, fasteners, etc. on the inside of the foundation, and the rest are implemented in the same way. example 1.

[0052] The anti-formwork construction method for underground deep foundation concrete of the present invention is widely used in the No. 4 and No. 6 oriented silicon steel projects of Qiangang No. 2 Cold Rolling of Shougang. There are more than 40 underground cable tunnels in this project, and the depth of the foundation pits is -5m~-7m. Between them, there are criss-crossing, compact layout, and dense equipment foundations, resulting in a narrow foundation pit and no operating space for supporting forms; the civil construction stage is catching up with the rare...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com