Rear sealing head heat-insulation layer structure for solid rocket engine and forming method of rear sealing head heat-insulation layer structure

A solid rocket and molding method technology, applied in rocket engine devices, machines/engines, mechanical equipment, etc., can solve the problems of interface combination bonding reliability is not as good as direct molding, cannot take into account comprehensive advantages, and has many molding processes. The effect of improving thermal protection performance, excellent comprehensive performance and simple molding method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Embodiment 1 A solid rocket motor rear head heat insulation layer structure and its forming method

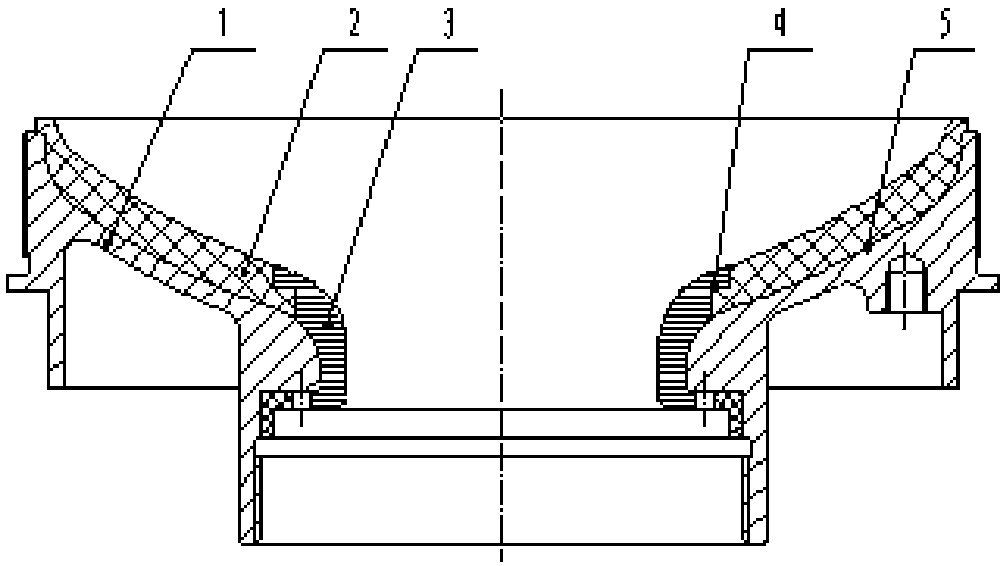

[0026] Such as figure 1 and figure 2 As shown, the heat insulation layer structure of the rear head of a solid rocket motor according to the present invention includes a heat insulation body, a lightweight rubber heat insulation layer 2 and an anti-ablation and anti-scouring heat insulation layer 3, wherein the heat insulation body 1 is used as a structural support, The lightweight rubber insulation layer 2 is arranged and distributed at the converging large end of the heat insulation body, and the anti-ablation and anti-scouring heat insulation layer 3 is arranged and distributed at the convergent narrow passage of the heat insulation body. For lap joints, the light rubber-type heat insulating layer and the anti-ablation and anti-erosion heat insulating layer are respectively preformed and placed on the heat insulating body for one-time thermosetting molding to form a...

Embodiment 2

[0032] Embodiment 2 A solid rocket motor rear head heat insulation layer structure and its forming method

[0033] The structure of the thermal insulation layer of the rear head of the solid rocket motor is the same as that in Embodiment 1. In the present invention, the lightweight thermal insulation material is EPDM rubber thermal insulation material; the anti-ablation and anti-scouring thermal insulation material is ablation-resistant fiber or fabric, and the body is made of metal.

[0034] A method for forming the heat insulation layer of the rear head of the above-mentioned solid rocket motor, which specifically includes the following steps:

[0035] 1) Preform the unvulcanized low-density rubber-type thermal insulation material, the preforming temperature is 50°C, the time is 3min, and the pressure is 5Mpa calculated according to the pressure bearing area of the preforming mold and the pressure of the equipment;

[0036] 2) Preform the uncured thermal insulation materi...

Embodiment 3

[0039] Embodiment 3 A solid rocket motor rear head heat insulation layer structure and its forming method

[0040] The structure of the thermal insulation layer of the rear head of the solid rocket motor is the same as that in Embodiment 1. In the present invention, the lightweight heat insulating material is nitrile rubber heat insulating material; the anti-ablation and anti-scouring heat insulating material is high silica fiber or fabric, and the body is made of metal.

[0041] A method for forming the heat insulation layer of the rear head of the above-mentioned solid rocket motor, which specifically includes the following steps:

[0042] 1) Prefabrication of unvulcanized low-density rubber-type thermal insulation material, the preformation temperature is 90°C, the time is 10min, and the pressure is 20MPa calculated according to the pressure bearing area of the preformation mold and the pressure of the equipment;

[0043] 2) Preform the uncured thermal insulation materia...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com