Mechanical-side drive fork-type roader roller

A technology for driving forks and road rollers, which is applied in the field of road rollers, can solve the problems of poor welt performance of rolling wheels, increased construction cost, poor compaction performance, etc., and achieves the effects of good welt performance, improved work efficiency, and large driving torque.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] In conjunction with the accompanying drawings, the following embodiments of the present invention are given, but the present invention is not limited to the following embodiments.

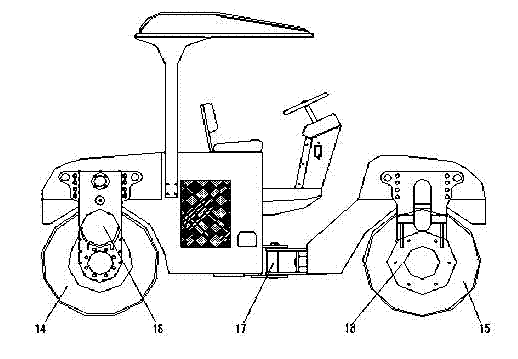

[0013] Such as figure 2 Shown: The machine-side drive fork-leg road roller described in this embodiment is mainly composed of a body 1 , a drive wheel 14 , a vibrating wheel 15 , an articulating frame 17 , fork legs 18 and a transmission mechanism 16 . The transmission mechanism is a mechanical side transmission structure, which is located on the side of the fuselage and the driving wheel.

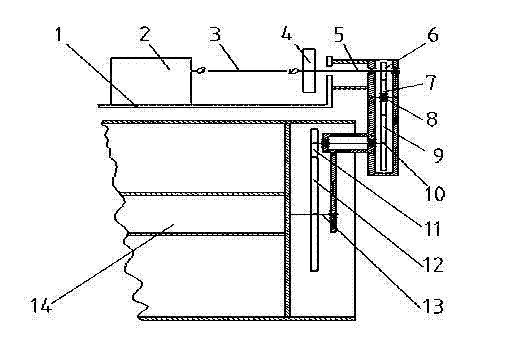

[0014] Such as figure 1 Shown: the power of the driving system - the diesel engine is transmitted to the driving wheel 14 through the gearbox 2, universal joint drive shaft 3, brake hub 4 and transmission mechanism 16 installed on the body 1, so that the road roller can be compacted and driving. The transmission mechanism 16 is located on the side of the fuselage 1 and the driving wheel 14 , and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com