An electroplating mold for high-precision selective electroplating

A selective and high-precision technology, applied in the direction of circuits, electrical components, electric solid devices, etc., can solve the problems of inaccurate plating area, unclear plating boundary, missing plating thickness, etc., to achieve clear plating boundary and prevent plating thickness The effect of unevenness and fast plating speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention is described in detail below in conjunction with accompanying drawing:

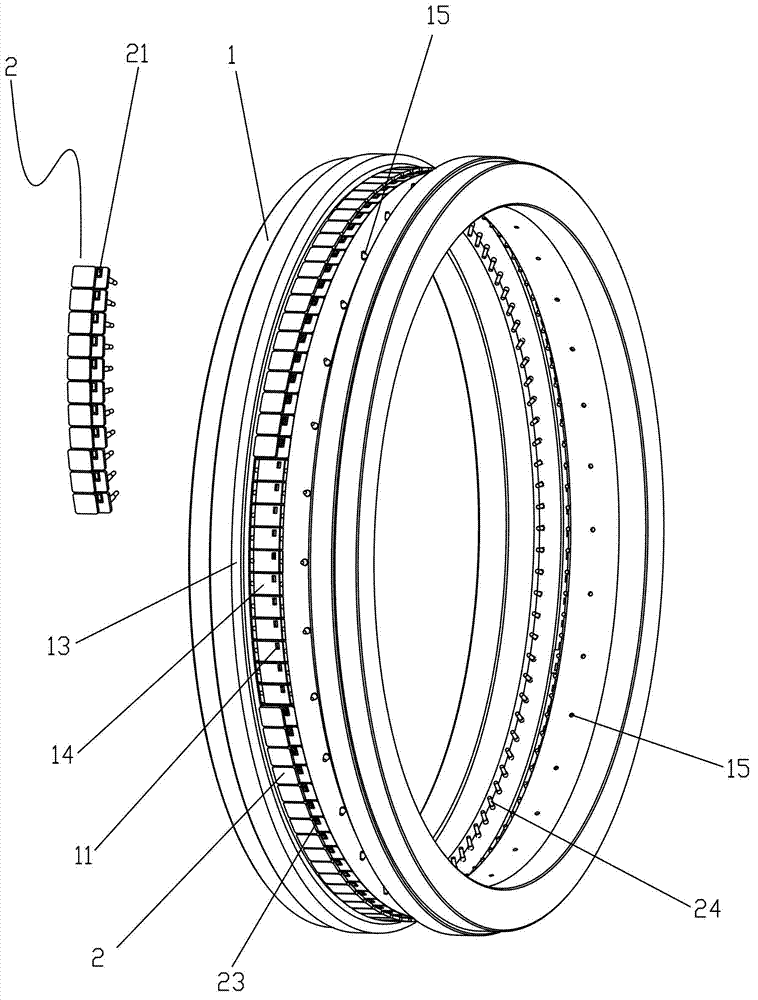

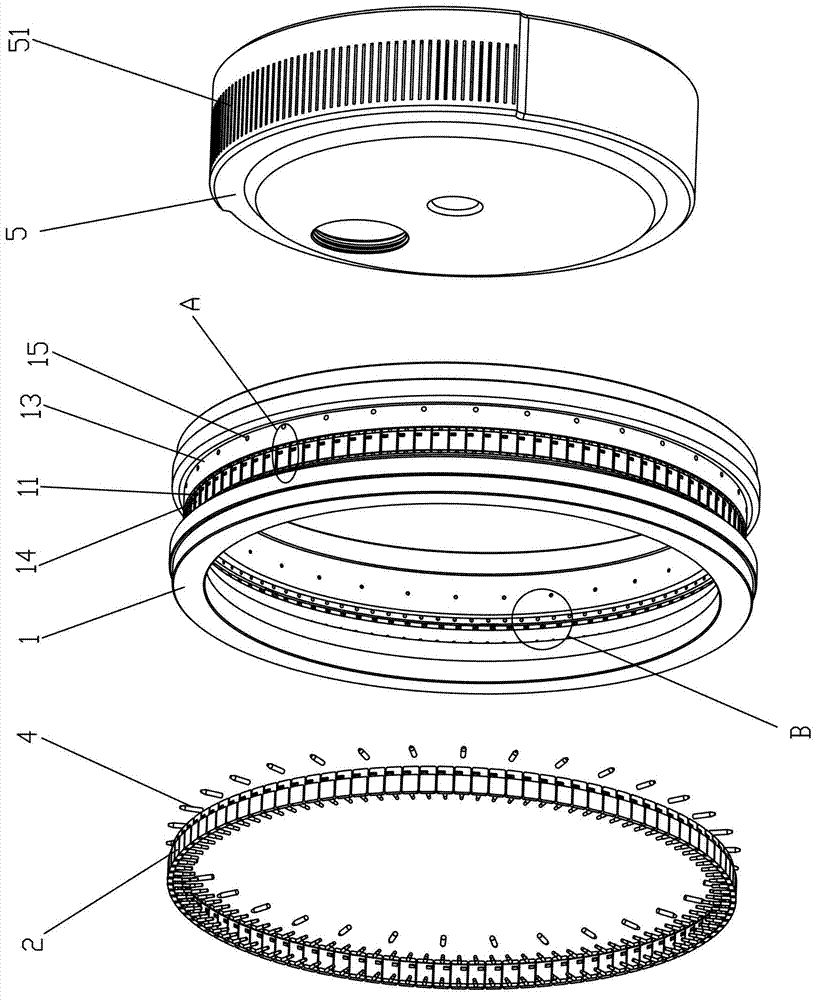

[0031] Such as Figure 1-9 Shown, a kind of electroplating mold that is used for high-precision selective electroplating, comprises roller type mold body 1 and is arranged on the mold body 1 peripheral wall and is used for covering the elastic mold belt 2 of non-plating area on the lead frame 3, on the mold body 1 A plurality of liquid spray holes 11 are arranged in the circumferential direction, and spraying openings 21 corresponding to the liquid spray holes 11 are provided on the elastic mold belt 2 .

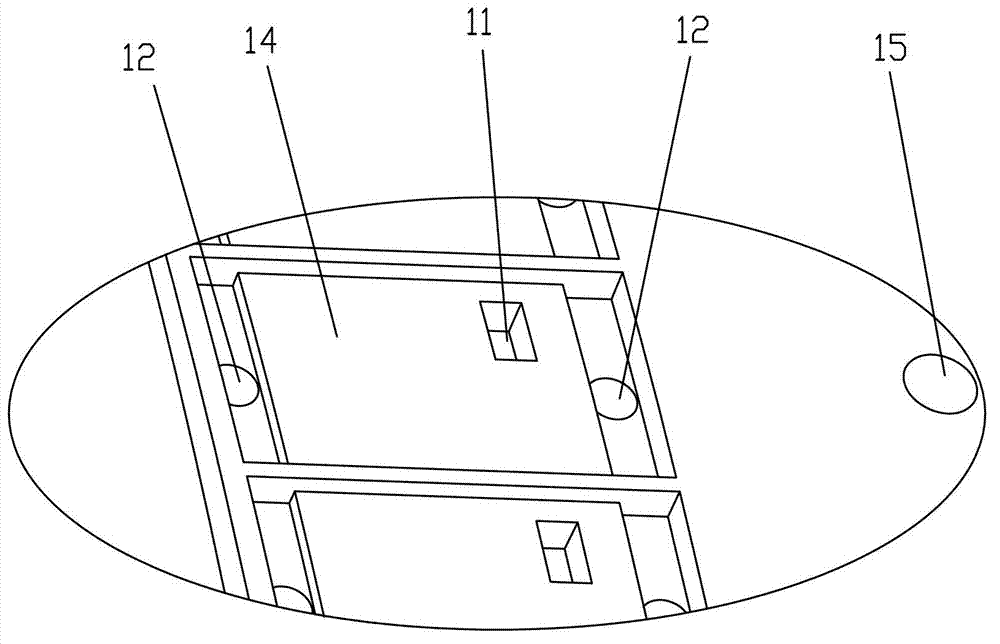

[0032] The mold body 1 is annular, and an annular groove 13 is arranged in the circumferential direction of the mold body 1, and a mold belt cavity 14 is arranged in the ring groove 13, and the liquid spray hole 11 is arranged in the mold belt cavity 14, and each liquid spray hole 11 both sides are provided with mold belt positioning hole 12, mold belt cavity 14 and mold be...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com