Filling compound for submarine optical fiber cables and preparation method of filling compound

An optical fiber cable and composite technology, which is applied in the field of filling compound for submarine optical fiber cable and its preparation, can solve problems such as poor waterproof and water blocking effect, oxidation and hydrogen evolution, etc., so as to improve water seepage problems, improve performance and life, and provide strong water resistance. The effect of water function

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

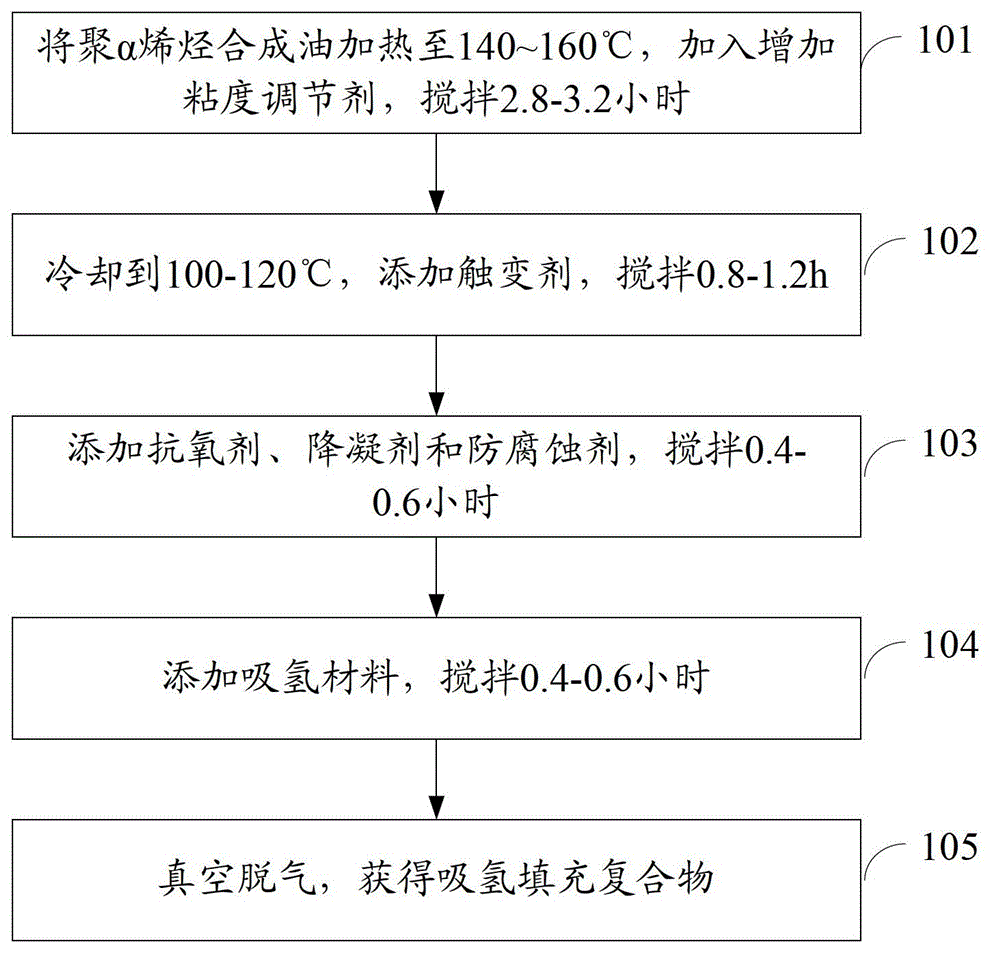

Method used

Image

Examples

Embodiment 1

[0024] Take 810g of polyalphaolefin synthetic oil and heat it up to 150°C, add 100g of ethylene-ethylene-propylene rubber block copolymer, stir for 3 hours, stir well and cool to 110°C, add 50g of meteorological silica, stir for 1h, then add 10g of high temperature The antioxidant, 5g of polymethacrylate pour point depressant and 10g of nonylphenoxyacetic acid anticorrosion agent were fully mixed, stirred for 0.5 hours to make them uniform, and finally 15g of hydrogen absorbing material was added and stirred for 0.5 hours. Then vacuum degassing, and finally a brown translucent paste is obtained.

Embodiment 2

[0026] Take 850g of polyalphaolefin and raise the temperature to 150°C, add 70g of ethylene-ethylene-propylene rubber block copolymer, stir for 3 hours, stir evenly and cool to 110°C, add 55g of meteorological silica, stir for 1h, and then add 7.5g of high-temperature resistant Oxygen agent, 5g polymethacrylate pour point depressant and 7.5g corrosion inhibitor are fully mixed, stirred for 0.5 hours to make it uniform, and finally 10g of hydrogen absorbing material is added and stirred for 0.5 hours. Then vacuum degassing, and finally a brown translucent paste is obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com