Paper pallet packaging cover board

A pallet and cover technology, used in packaging, transportation and packaging, paper/cardboard layered products, etc., can solve the problems of paper damage, heavy wood packaging cover, complicated procedures, etc., to avoid paper damage, strengthen Publicity effect, the effect of simple production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

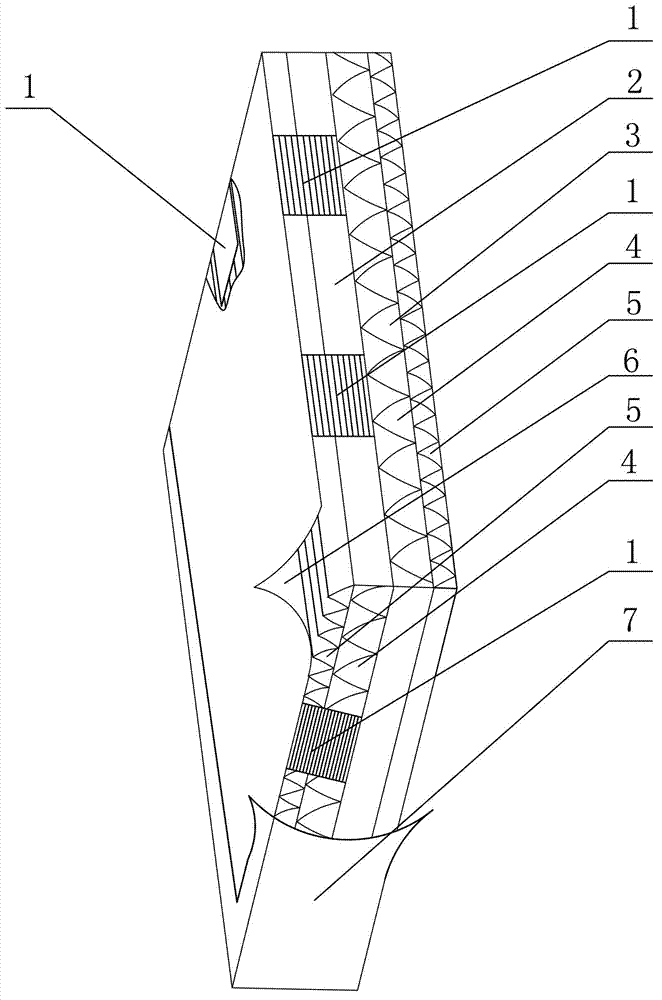

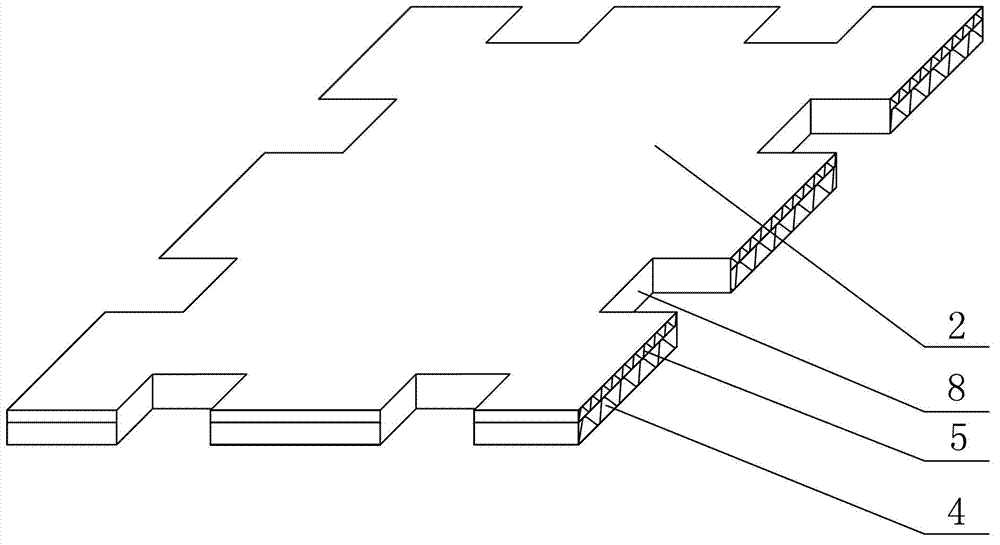

[0019] Embodiment one: if figure 1 As shown, a paper pallet packaging cover plate includes a body, the body includes an upper plate 2 and a lower plate 3, the upper plate 2 and the lower plate 3 are composed of at least two corrugated cardboards of different corrugated types, the upper plate 2 and the lower plate 3 The flute direction of the cardboard on the contact surface of the lower board 3 is criss-crossed. The four sides of the upper plate 2 are provided with a packing liner 1 having the same thickness as the packing liner 1. The packing liner 1 is formed by bonding a plurality of cardboards, and the type of the cardboards can be selected according to different situations.

[0020] The four sides of the upper plate 2 are flush with the four sides of the lower plate 3, and the four sides of the upper plate 2 are provided with a plurality of gaps 8, and the packaging liner 1 matches the shape of the gaps 8, lining each In the notch 8 , the exposed side edge of the packagi...

Embodiment 2

[0025] Embodiment 2: The other parts are the same as in Embodiment 1, the difference is that the packaging liner 1 is in the shape of a strip and surrounds the four sides of the upper plate 2, and the exposed side of the packaging liner 1 is connected to the lower plate. The side edges of 3 are flush, and in this specific embodiment, the width of this packing liner 1 is 5-6cm.

Embodiment 3

[0026] Embodiment 3: Other parts are the same as Embodiments 1 and 2, the difference is that the upper plate 2 and the lower plate 3 are made of B-type corrugated cardboard and E-type corrugated cardboard with staggered and vertical directions.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com