Lower die of bending machine and auxiliary mechanism of lower die

A technology of auxiliary mechanism and bending machine, which is applied in the direction of metal processing equipment, forming tools, manufacturing tools, etc., can solve the problems of affecting the appearance of the product, the decline of the process performance of the aluminum plate, and the surface indentation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

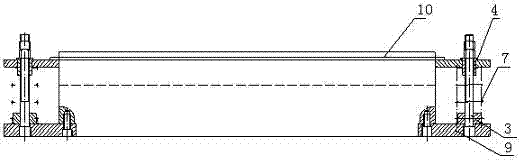

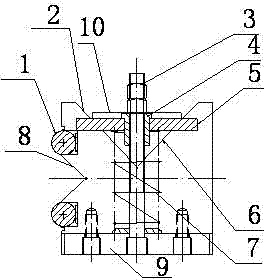

[0014] Such as Figure 1-2 As shown, the lower mold has two V-shaped grooves, and the auxiliary mechanism is fixed on both sides of the first V-shaped groove 6. The mechanism includes a movable positioning plate 5, a spring 7, a bushing 4, a lead screw 3 and a base 9. The guide screw 3 is vertically connected to the movable positioning plate 5, a bushing 4 is arranged between the guide screw 3 and the movable positioning plate 5, the guide screw 3 passes through the spring, and the spring 7 is pressed under the movable positioning plate 5, and the bottom of the guide screw 3 is fixed on the on base 9.

[0015] The auxiliary mechanism also has rollers 1 arranged on both sides of the top of the second V-shaped groove 8 , and the slope of the second V-shaped groove 8 is tangent or intersected with the peripheral surface of the roller 1 .

[0016] The two sides of the second V-shaped groove 8 of the lower mold 2 have grooves for placing the rollers 1. The rollers 1 can rotate aro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com